Method for extracting chlorogenic acid from Chinese wolfberry

A technology of chlorogenic acid and wolfberry is applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., to achieve the effects of increasing added value, lowering extraction cost, and shortening extraction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

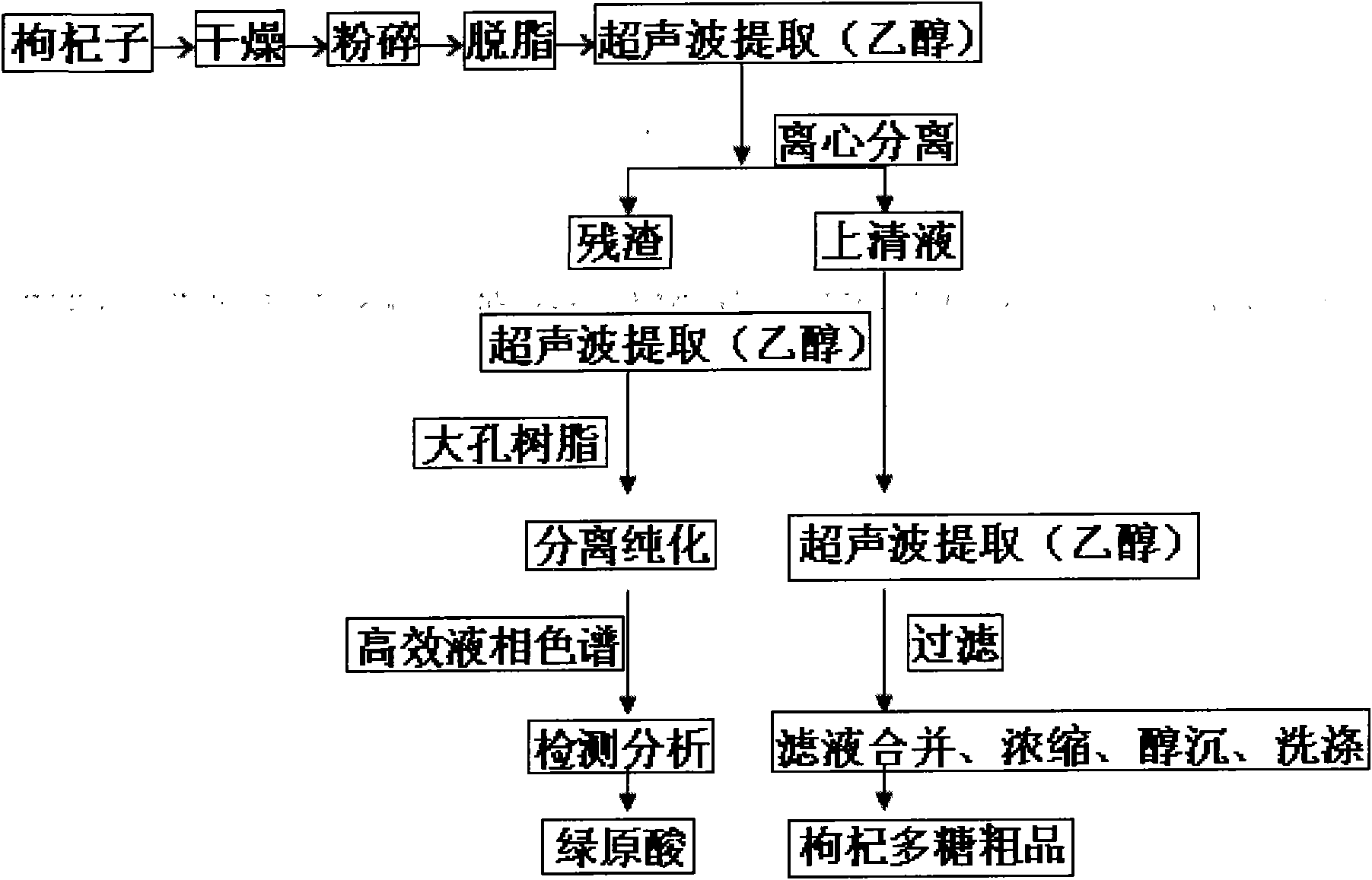

[0028] 1) Lycium barbarum fruit pretreatment step Lycium barbarum fruit is first dried in an oven, taken out and placed in a drying room to stand for 24 hours, crushed and placed in an ordinary reflux device for degreasing, filtering out the solvent, and air-drying the residue for later use.

[0029] 2) The step of extracting Lycium barbarum polysaccharides uses ethanol as a solvent, and adopts an ultrasonic-assisted method. The extract is concentrated, alcohol-precipitated, and dried to obtain Lycium barbarum polysaccharide coarse powder; the process conditions are: the volume fraction of ethanol is 50%, and the ratio of solid to liquid is 1: 20. The extraction time is 50 minutes, and the number of extractions is 2 times;

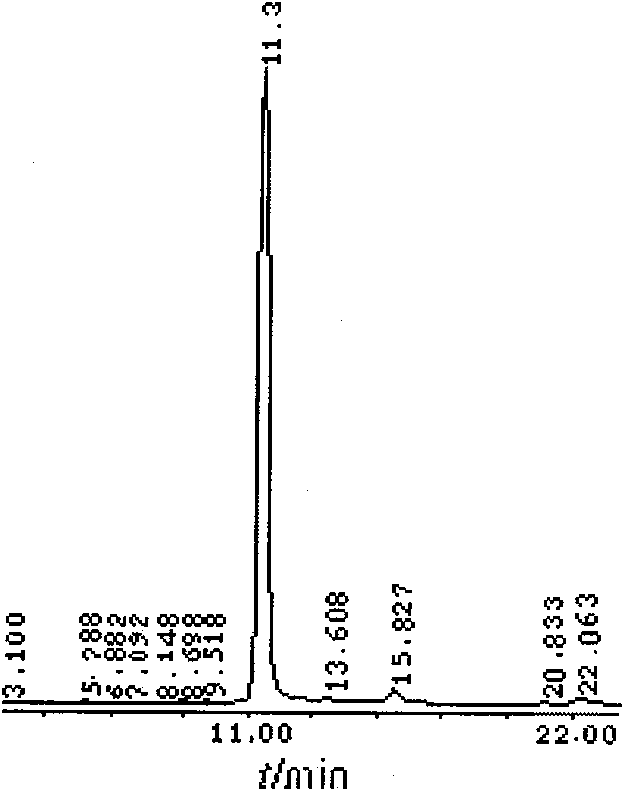

[0030] 3) The step of extracting chlorogenic acid from Lycium barbarum extracts the residue after extracting Lycium barbarum polysaccharides, using ethanol as a solvent, extracting chlorogenic acid from Lycium barbarum by ultrasonic-assisted method, separat...

Embodiment 2

[0033] 1) Lycium barbarum fruit pretreatment step Lycium barbarum fruit is first dried in an oven, taken out and placed in a drying room to stand for 24 hours, crushed and placed in an ordinary reflux device for degreasing, filtering out the solvent, and air-drying the residue for later use.

[0034] 2) The step of extracting Lycium barbarum polysaccharides uses ethanol as a solvent, adopts the ultrasonic-assisted method, and the extract is concentrated, alcohol-precipitated, and dried to obtain Lycium barbarum polysaccharide coarse powder; the process conditions are: the volume fraction of ethanol is 60%, and the ratio of solid to liquid is 1: 30, the extraction time is 60 minutes, and the number of extractions is 3 times.

[0035] 3) The step of extracting chlorogenic acid from Lycium barbarum extracts the residue after extracting Lycium barbarum polysaccharides, using ethanol as a solvent, extracting chlorogenic acid from Lycium barbarum by ultrasonic-assisted method, separa...

Embodiment 3

[0038] 1) Lycium barbarum fruit pretreatment step Lycium barbarum fruit is first dried in an oven, taken out and placed in a drying room to stand for 24 hours, crushed and placed in an ordinary reflux device for degreasing, filtering out the solvent, and air-drying the residue for later use.

[0039] 2) The step of extracting Lycium barbarum polysaccharides uses ethanol as a solvent, and adopts an ultrasonic-assisted method. The extract is concentrated, alcohol-precipitated, and dried to obtain Lycium barbarum polysaccharide coarse powder; the process conditions are: the volume fraction of ethanol is 70%, and the ratio of solid to liquid is 1: 40, the extraction time is 70 minutes, and the number of extractions is 4 times;

[0040] 3) The step of extracting chlorogenic acid from Lycium barbarum extracts the residue after extracting Lycium barbarum polysaccharides, using ethanol as a solvent, extracting chlorogenic acid from Lycium barbarum by ultrasonic-assisted method, separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com