Xanthophyll extraction process

An extraction process, lutein technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problem of no extraction of lutein, shorten the extraction time, reduce the one-time investment of equipment, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

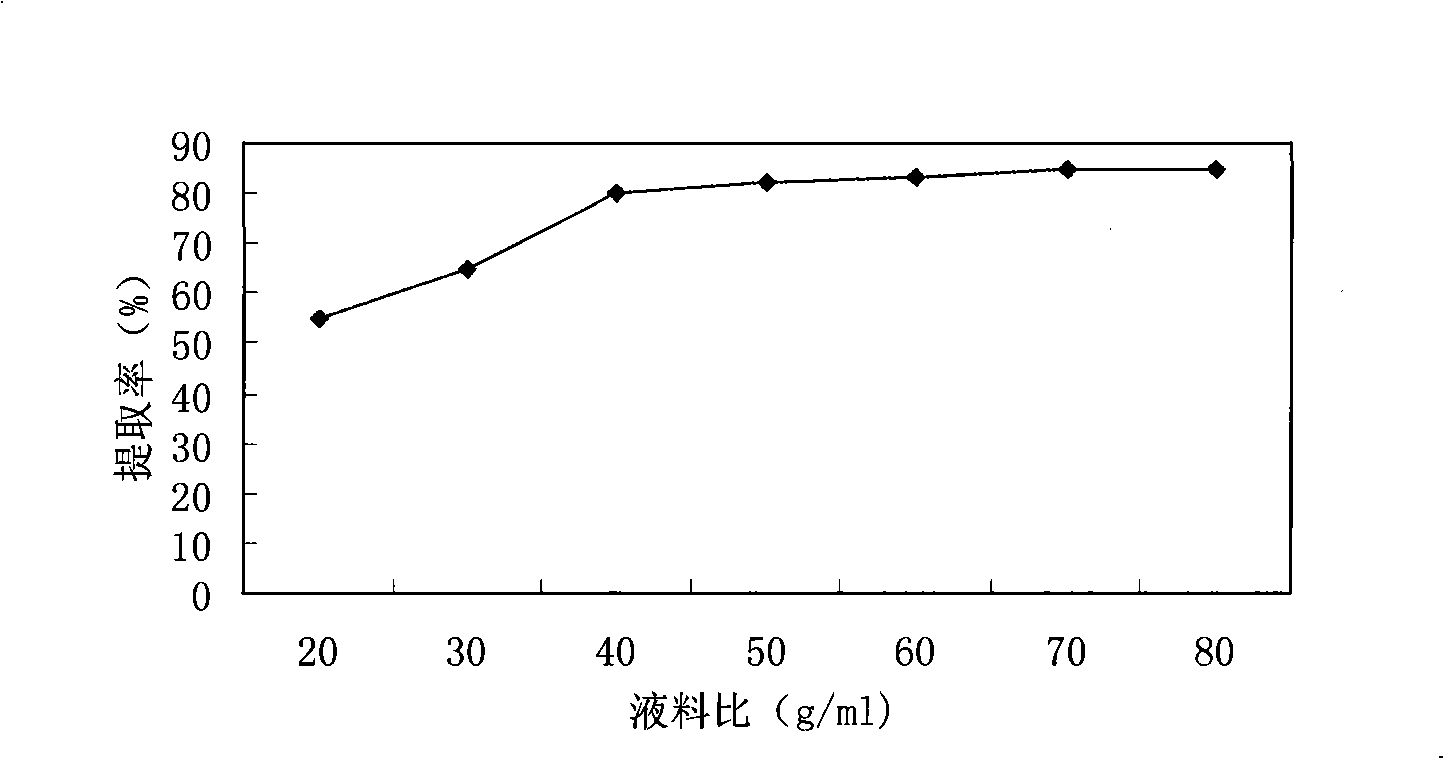

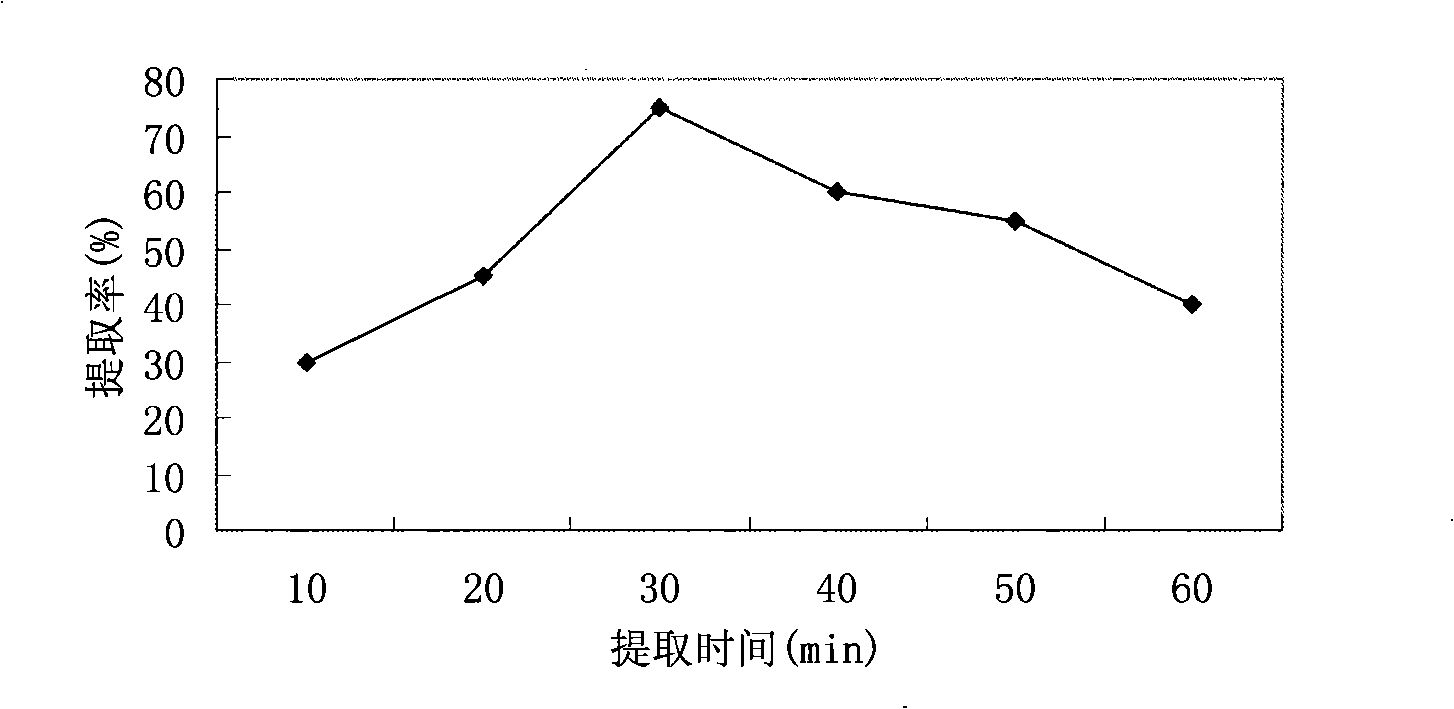

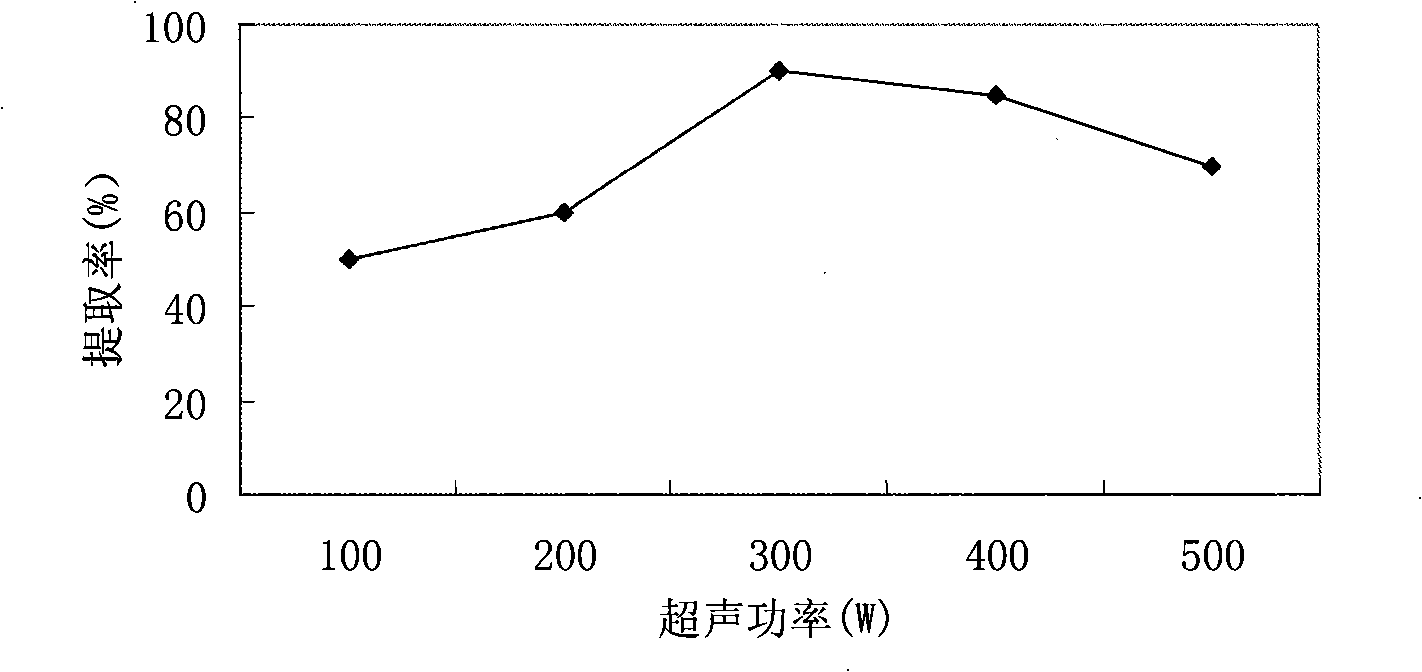

Method used

Image

Examples

Embodiment 1

[0021] Take 1 kg of marigold flower, dry, pulverize, add 20L n-hexane / acetone / methanol (volume ratio is 8:1:1), at 20°C, ultrasonic power 100W, ultrasonic extraction for 20 minutes. Take it out, put it into a centrifuge, and spin and centrifuge at 5000r / min to obtain a clarified lutein supernatant. Add 2 times its volume of 20% (mass concentration) potassium hydroxide ethanol solution to the supernatant, and control the temperature at 50-70° C. to carry out saponification reaction for 30-50 minutes. After the saponification reaction is complete, let stand and cool. The reaction product was fully washed with deionized water until the lutein was crystallized and neutral, and centrifuged to obtain crude lutein crystals. Crude lutein crystals were dissolved in 150 ml of tetrahydrofuran, and 250 ml of deionized water was added for recrystallization. The recrystallized lutein crystals were washed with deionized water and ethanol, and dried to obtain 3.58 grams of finished lutein c...

Embodiment 2

[0023] Take 1 kg of marigold flowers, dry, crush, add 40L n-hexane / acetone / methanol (8:1:1 volume ratio), and extract by ultrasonic wave for 30 minutes at 30°C with ultrasonic power of 300W. Take it out, put it into a centrifuge, and spin and centrifuge at 5000r / min to obtain a clarified lutein supernatant. Add 20% (mass concentration) potassium hydroxide ethanol solution twice the volume of the supernatant to the supernatant, and control the temperature at 50-70° C. for saponification for 30-50 minutes. After the saponification reaction is complete, let stand and cool. The reaction product was fully washed with deionized water until the lutein was crystallized and neutral, and centrifuged to obtain crude lutein crystals. Crude lutein crystals were dissolved in 150 ml of tetrahydrofuran, and 250 ml of deionized water was added for recrystallization. The recrystallized lutein crystals were washed with deionized water and ethanol, and dried to obtain 3.68 g of finished lutein ...

Embodiment 3

[0025] Take 1 kg of marigold flower, dry, pulverize, add 20L n-hexane / acetone / methanol (volume ratio is 8:1:1), at 40°C, ultrasonic power 300W, ultrasonic extraction for 30 minutes. Take it out, put it into a centrifuge, and spin and centrifuge at 5000r / min to obtain a clarified lutein supernatant. Add 20% (mass concentration) potassium hydroxide ethanol solution twice the volume of the supernatant to the supernatant, and control the temperature at 50-70° C. for saponification for 30-50 minutes. After the saponification reaction is complete, let stand and cool. The reaction product was fully washed with deionized water until the lutein was crystallized and neutral, and centrifuged to obtain crude lutein crystals. Crude lutein crystals were dissolved in 150 ml of tetrahydrofuran, and 250 ml of deionized water was added for recrystallization. The recrystallized lutein crystals were washed with deionized water and ethanol, and dried to obtain 3.66 grams of finished lutein cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com