Fire-proof heat insulation composite decorative plate and manufacture process thereof

A technology for fire prevention and heat preservation and production process, applied in ceramic products, other household appliances, applications, etc., can solve the problems of high cost and can not meet the effect of heat preservation, and achieve the effect of low cost, good heat preservation and fire prevention effect, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

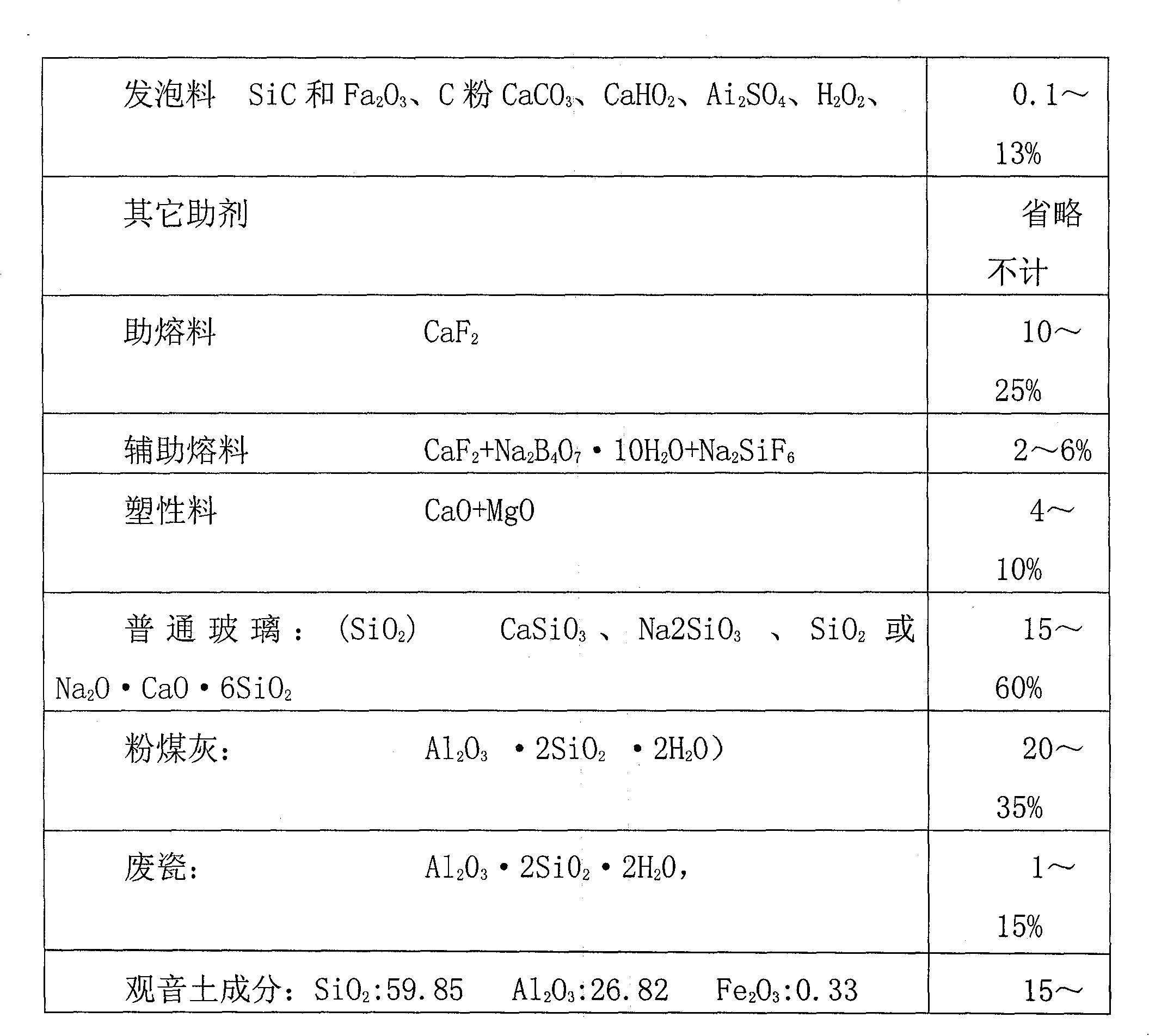

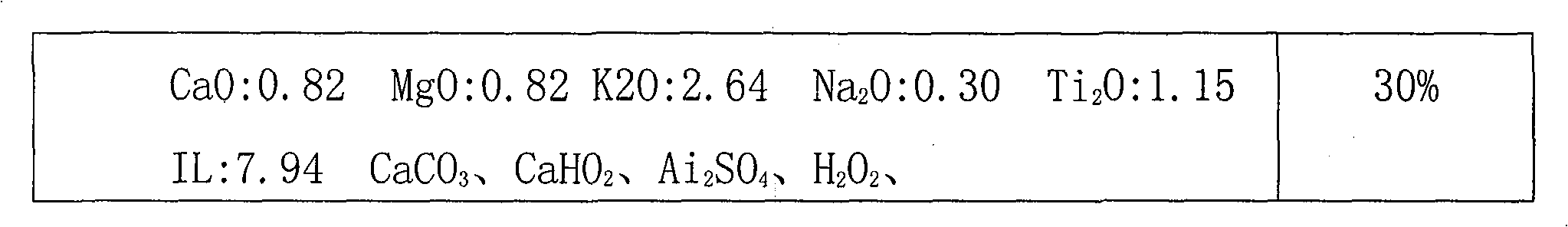

[0025] It includes a veneer and a bottom layer, and foamed ceramics are arranged between the veneer and the bottom layer, and the foamed ceramics include 15-30% of Guanyin soil, 15-60% of broken glass, and 1-15% of broken waste porcelain , Fly ash 20-35%.

[0026] The production process includes material preparation, basic treatment of decorative panels, surface treatment of decorative panels, rolling or spraying paint, inner surface treatment of decorative panels, component installation, cutting or splicing of foam ceramics, installation or bonding on decorative panels, inspection, and finished products.

[0027] The manufacturing process of the foamed ceramics includes

[0028] 1) Avalokitesvara soil 15-30%, pound mud, mud sedimentation, porcelain mud for later use;

[0029] 2) 15-60% of waste glass and porcelain, 1-15% of broken waste porcelain, 20-35% of fly ash, ball milling, dry screening, fine grinding;

[0030] 3) Mixing and stirring, the above materials are mixed an...

Embodiment 1

[0054] The composition of foam ceramics is 10% aluminum oxide, 85% silicon dioxide, 2% waste porcelain, 5% fluorite, 4% feldspar quartz, 3% iron oxide and carbon, and 5% porcelain clay. , fly ash 20%, silicon carbide 0.15% through ball milling, drying and screening, fine grinding, mixing porcelain clay, stirring, cold pressing, billet drying, 1180 ℃ furnace temperature, roller kiln firing, heat preservation and cooling, and discharge The bulk density of the finished product after the kiln (0.265g / cm 3 ) that is 0.8m×0.6m×0.03m / 3.816kg / . Determination of compressive strength 3.35MPa. Thermal conductivity≤0.056(W / m.K)25℃298K. Meet the requirements of exterior wall insulation decorative panels.

[0055] Then we provide an aluminum alloy plate, galvanized plate, inorganic cement plate, plastic plate, etc. with a thickness of 0.5 ~ 8.0mm or more as a decorative surface (roller coating, spraying various fluorocarbon paints, PU, UV, PE and other coating surfaces) Its production...

Embodiment 2

[0057] The composition of foam ceramics is 17% of aluminum oxide, 70% of silicon dioxide, 20% of fluorite, 4% of feldspar quartz, 5% of ferric oxide and carbon, 22% of porcelain clay, and 20% of fly ash. , through ball milling, drying screening, fine grinding, mixing porcelain clay, stirring, cold pressing, blank drying, 1180 ℃ furnace temperature, roller kiln firing, heat preservation and cooling, and the volume density of the finished product after exiting the kiln (0.37g / cm 3 ) that is 0.8m×0.6m×0.03m / 5.328kg / . Determination of compressive strength 4.00MPa. Thermal conductivity≤0.056(W / m.K)25℃298K. Meet the requirements of exterior wall insulation decorative panels.

[0058] Then we provide an aluminum alloy plate, galvanized plate, inorganic cement plate, plastic plate, etc. with a thickness of 0.5 ~ 8.0mm or more as a decorative surface (roller coating, spraying various fluorocarbon paints, PU, UV, PE and other coating surfaces) Its production process: Fold the edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com