Method for observing real topography of nonmetallic inclusion in steel

A technology for non-metallic inclusions and observation of steel, which is applied in the field of characterizing the morphology of non-metallic inclusions in steel, can solve the problems of long electrolysis time, difficult operation, and reduced analysis accuracy, and achieve complete morphology and simple sample preparation Effect

Active Publication Date: 2010-08-25

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(2) Image scanning method (IA); use a high-speed computer microscope to scan the image, and distinguish light and dark areas according to the intermittent grayscale, which is easy to measure a large area and a large number of inclusions, with a high degree of automation, and can obtain volume fraction and particle size Distribution histogram, quantitative and other information, but it is susceptible to interference such as scratches, pits, pits, dust, etc., which reduces the accuracy of analysis

There are many traditional methods for characterizing non-metallic inclusions, but it is not easy to directly observe the real three-dimensional shape of non-metallic inclusions in steel

The metallographic method can only observe the two-dimensional shape of the inclusions. Although the electrolysis method can extract the non-metallic inclusions in the steel, the shape of the inclusions is easily destroyed during the electrolysis and elutriation process, and the chemical composition is easily affected by the anode during the electrolysis process. The influence of the reaction is inaccurate, and there are disadvantages such as long electrolysis time and difficult operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

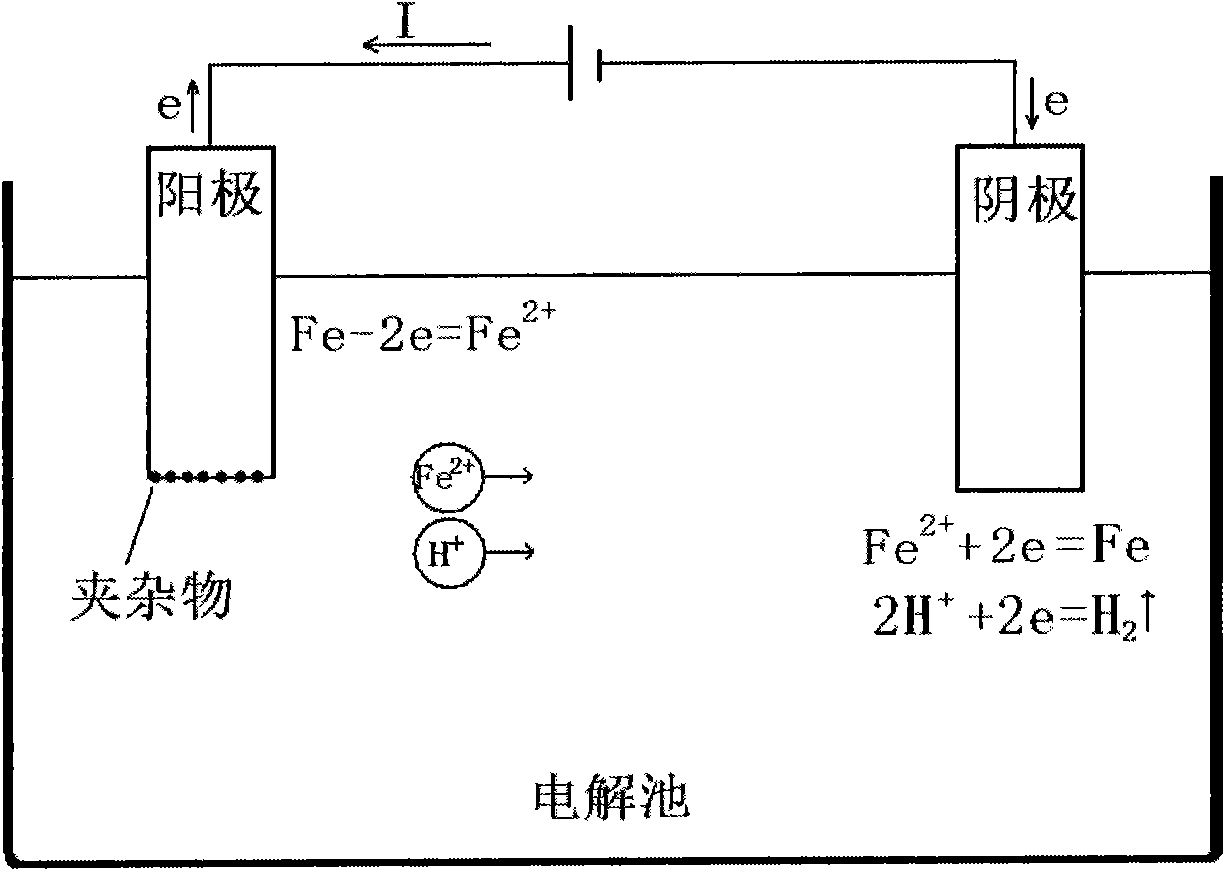

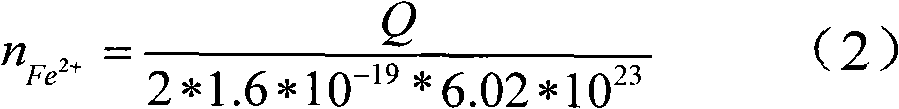

The invention discloses a method for observing real topography of nonmetallic inclusion in steel, which belongs to the technical field of steelmaking and continuous casting. The method comprises the following steps: preparing a metallographic model, then mixing several of organic solves such as bromine water, methanol, ethanol, acetone and the like to form buffer solution, adding KCl or NaCl or HCl solution into the buffer solution to form electrolyte, performing surface electrolysis corrosion on the polished metallographic model by using the electrolyte, and controlling the corrosion thickness by controlling electrolysis current and electrolysis time, wherein the nonmetallic inclusion is highlighted on the mirror face of the metallographic model after the corrosion and the real topography of the nonmetallic inclusion with different dimensions is completely represented. The three-dimensional real topography of the nonmetallic inclusion is observed through a metallographic microscope or a scanning electron microscope or a field emission scanning electron microscope. The application and popularization of the method are favorable for deeper comprehension and development of people on the formation, transformation and removal of the nonmetallic inclusion during the steelmaking and continuous casting, and have great guide significance for high-purity steel production.

Description

technical field The invention belongs to the technical field of steelmaking and continuous casting, and in particular provides a method for characterizing the morphology of non-metallic inclusions in steel, which can control the cleanliness of molten steel and various types of non-metallic inclusions in the steelmaking and continuous casting process. It is of great significance to reveal the real morphology existing in molten steel. Background technique Non-metallic inclusions in steel greatly affect the purity of molten steel. As the requirements for steel quality become more and more stringent, how to effectively understand and improve non-metallic inclusions in steel is becoming more and more important. Only by having an accurate understanding of the shape of non-metallic inclusions in steel can they be well controlled and removed during the smelting process. The traditional methods for characterizing inclusions in steel mainly include: (1) Metallographic Microscopic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25F3/06

Inventor 王敏包燕平吴维双崔衡

Owner UNIV OF SCI & TECH BEIJING

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com