Magnetron sputtering plating film cathode device

A magnetron sputtering coating and cathode technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of large changes in the magnetic field strength of the magnetic bar, uneven film thickness, and uneven magnetic field. , to achieve the effects of small temperature difference, improved coating uniformity, and uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

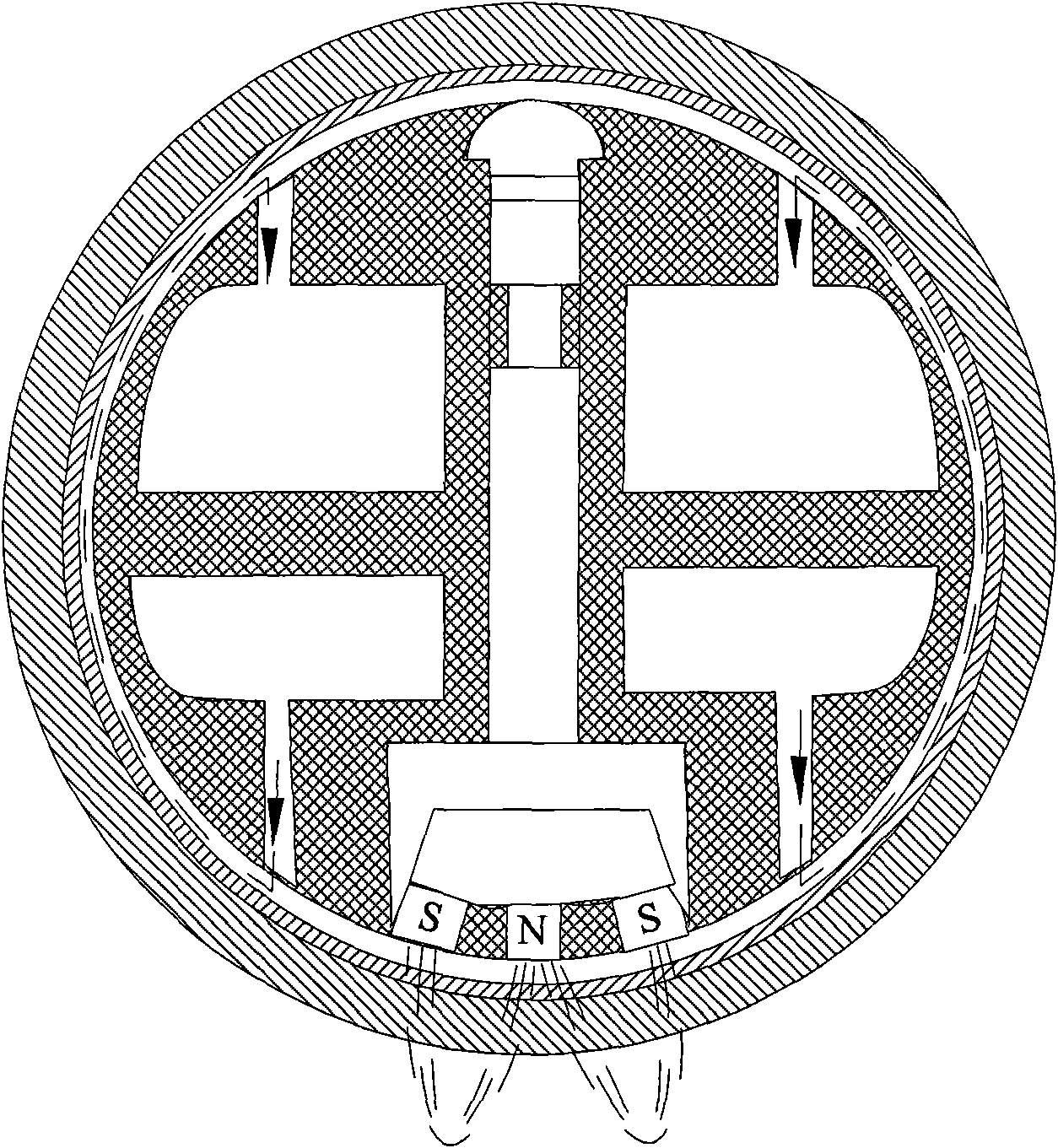

[0018] The structure of the magnetron sputtering coating cathode device (hereinafter referred to as the rotating cathode) will be mainly described below with reference to the accompanying drawings. By uniformly cooling the sputtering area, there is no temperature difference between the two ends of the target, and the magnetic field is stable during the sputtering process, which can make the coating thickness uniform.

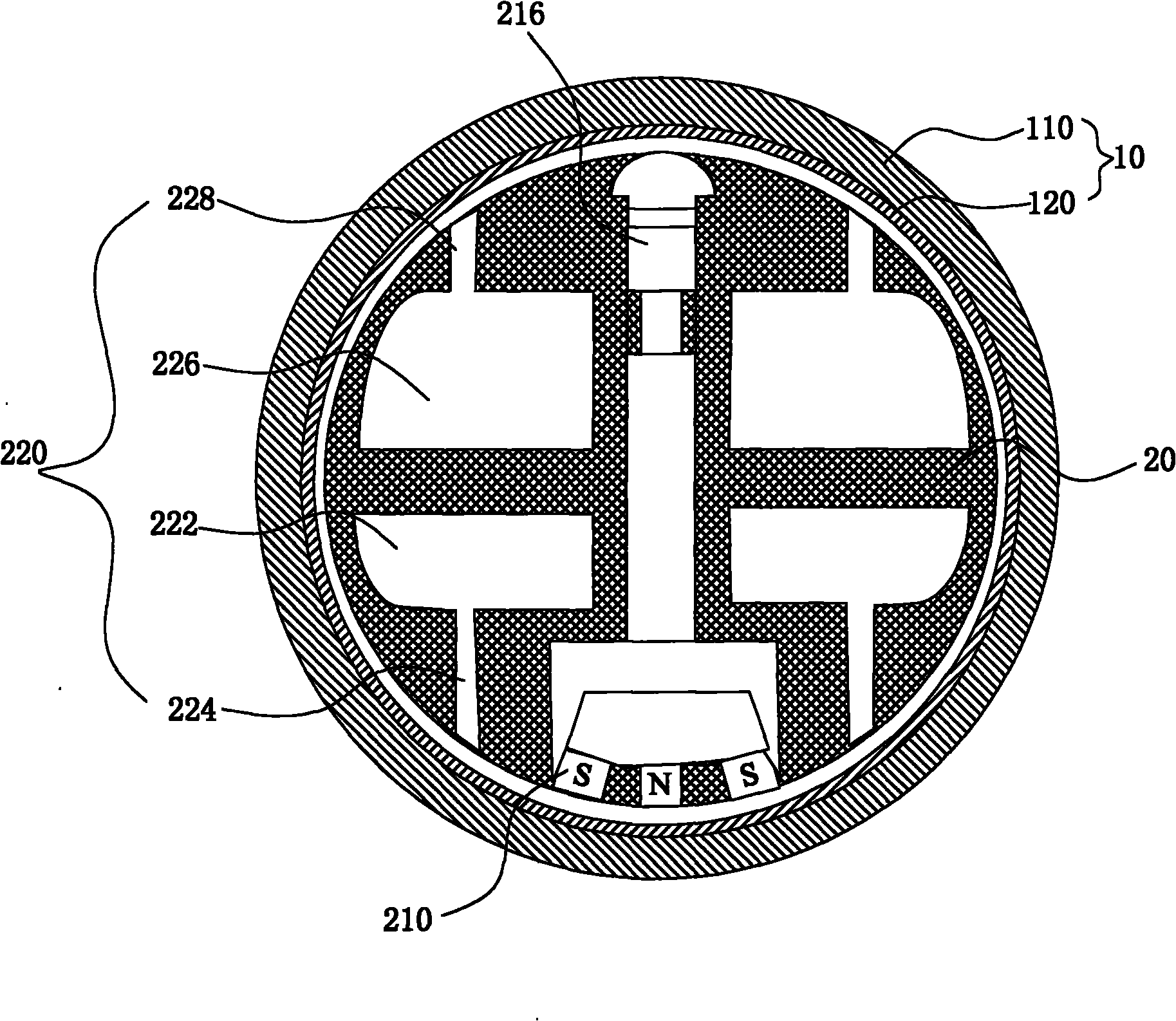

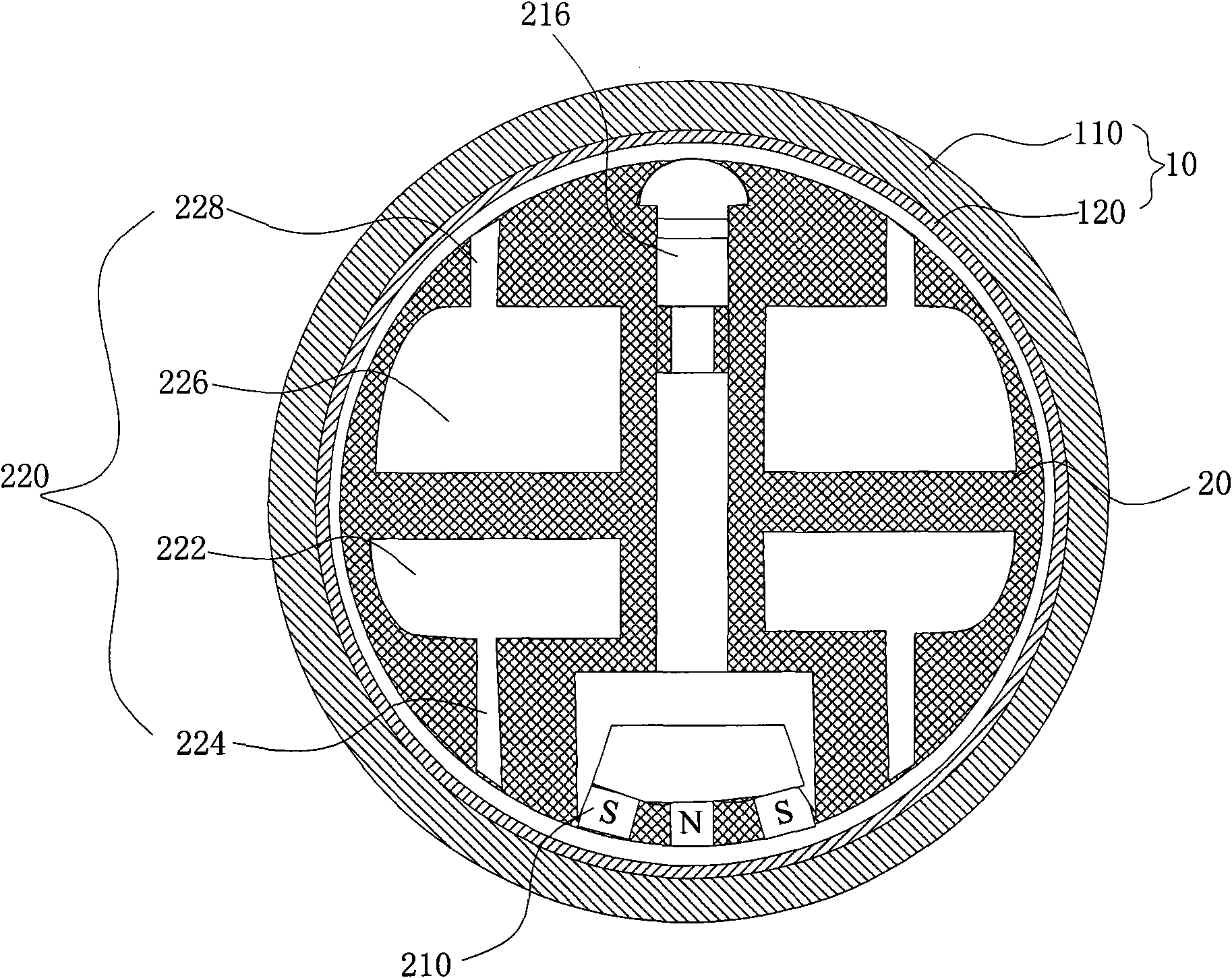

[0019] FIG. 1 is a cross-sectional view of a magnetron sputtering coating cathode device, which includes a target cylinder 10 and a magnetic rod tube 20 . The target cylinder 10 has a cylindrical structure and includes a sputtering target 110 and a target inner cylinder 120 . The sputtering target 110 evenly covers the target inner cylinder 120 and forms an integral body with the target inner cylinder 120 .

[0020] The magnetic rod pipe 20 is located in the target cylinder 10 , and a magnet 210 is installed inside the magnetic rod pipe 20 and a cooling water ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com