Wind driven generator

A wind turbine and cold air technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of natural ventilation and heat dissipation of generators, affecting the use effect of generators, and increasing local temperature of generators, etc., and achieve good promotion. Value, compact structure, the effect of reducing the cooling air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

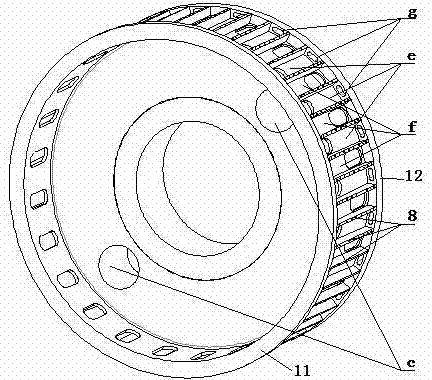

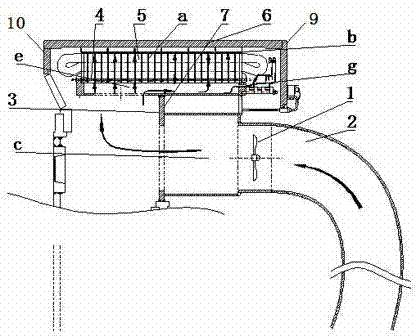

[0018] Such as Figure 1~4 As shown: the present invention is a direct-drive wind generator with a special ventilation and cooling structure, and a rotor 6 and a stator base 3 that cooperate with each other are arranged in the casing of the wind generator. The front end cover 9 of the casing corresponds to the non-driving end of the wind generator, and the rear end cover 11 corresponds to the driving end of the wind generator.

[0019] Both sides of the outer circumferential surface of the stator frame 3 are respectively provided with a front side baffle 11 and a rear side baffle 12, the front side baffle 11 and the rear side baffle 12 are annular, and are fixedly connected to the side of the stator frame 3. Both sides of the outer peripheral surface, and the height of the front side baffle 11 and the rear side baffle 12 are higher than the outer peripheral surface by a certain distance, so that a circle of annular grooves is formed near the outer peripheral surface of the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com