Uniform-cooling cooling roller device and method for amorphous strip preparing

An amorphous strip, uniform cooling technology, applied in the field of amorphous broadband preparation, can solve the problems of difference in performance at both ends of the strip, different temperatures at both ends, uneven temperature field on the surface of the roller sleeve, etc., to achieve uniform temperature field. , the effect of uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

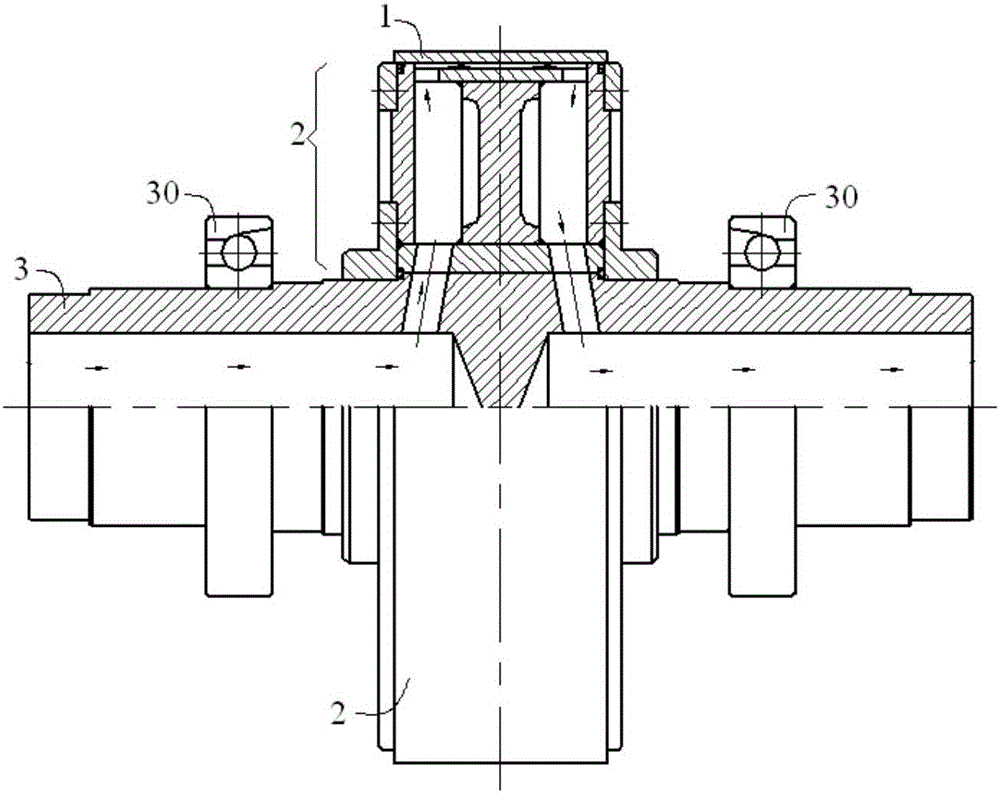

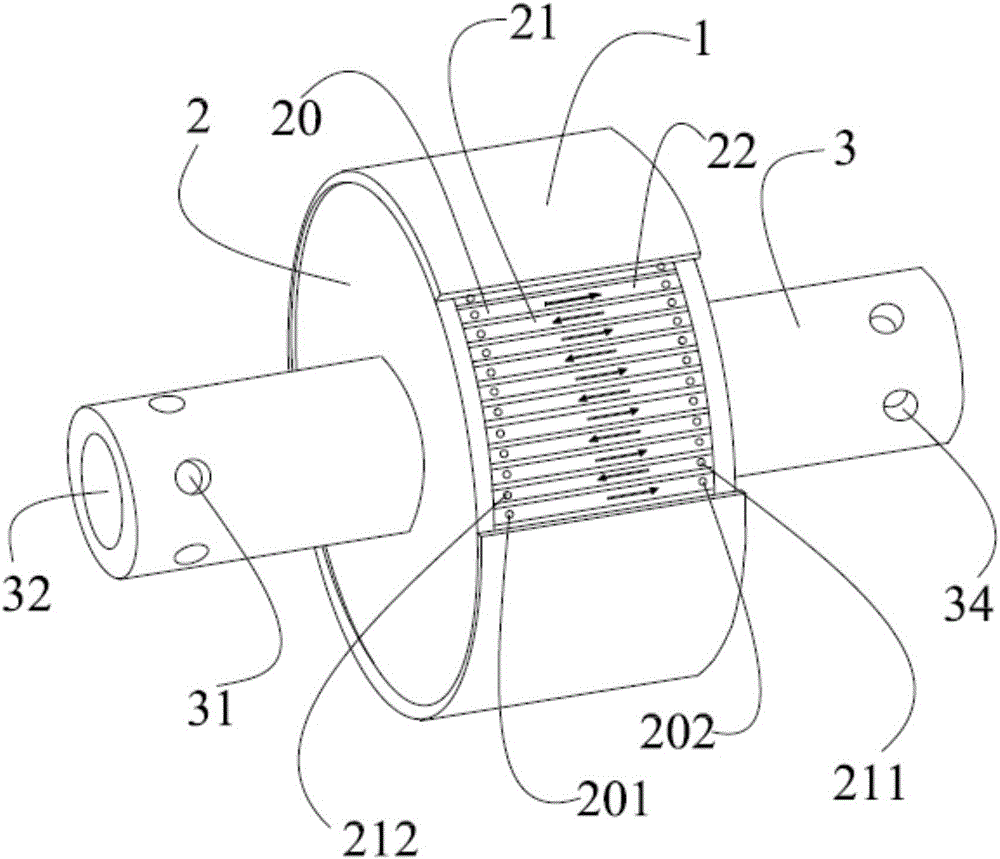

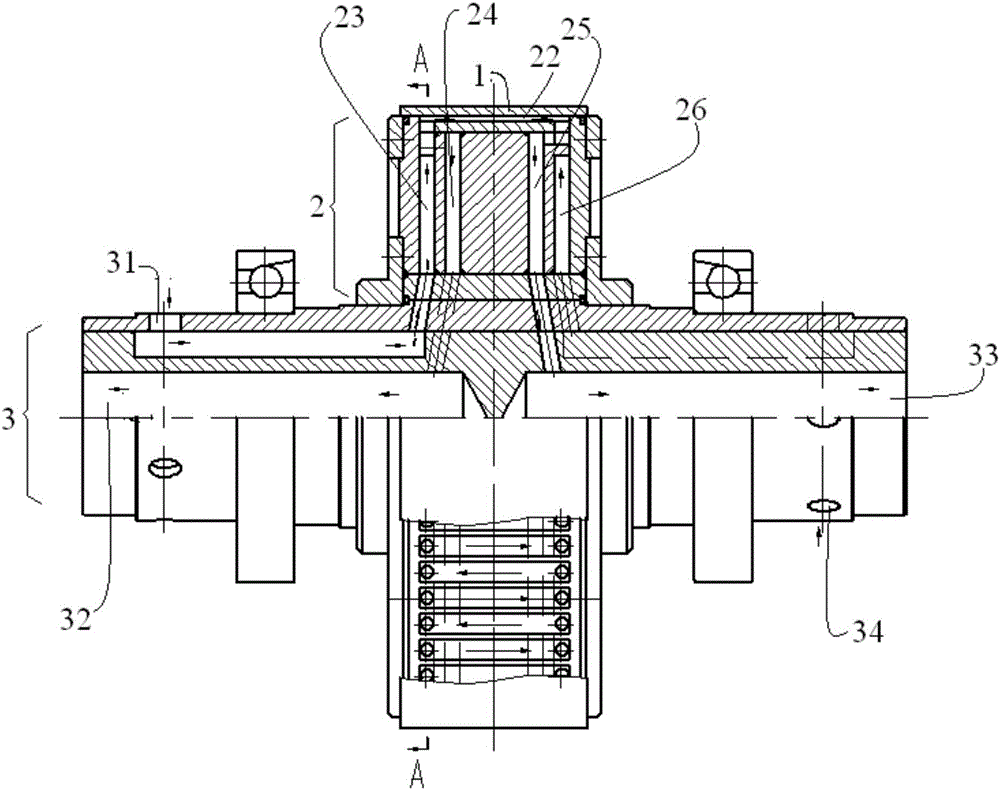

[0024] see Figure 2-6 , the embodiment of the present invention provides a cooling roll device for uniform cooling used in the preparation of amorphous strips, which includes: a support shaft 3 , a roll core 2 and a roll sleeve 1 . The roller core 2 is sleeved on the circumferential outer side of the support shaft 3 , the roller sleeve 1 is sleeved on the circumferential outer side of the roller core 2 , and the roller core 2 and the roller sleeve 1 are driven by the rotation of the support shaft 1 to rotate together. The roller sleeve 1 and the roller core 2, and the roller core 2 and the support shaft 3 are preferably assembled by thermal assembly to realize socketing. A first cooling liquid passage 20 and a second cooling liquid pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com