Anti-blocking tube heating device for sponge production

A heating device and anti-blocking pipe technology, which is applied in the field of non-ferrous metal smelting, can solve problems such as easy blockage, and achieve the effects of fast heating speed, shortened distillation time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

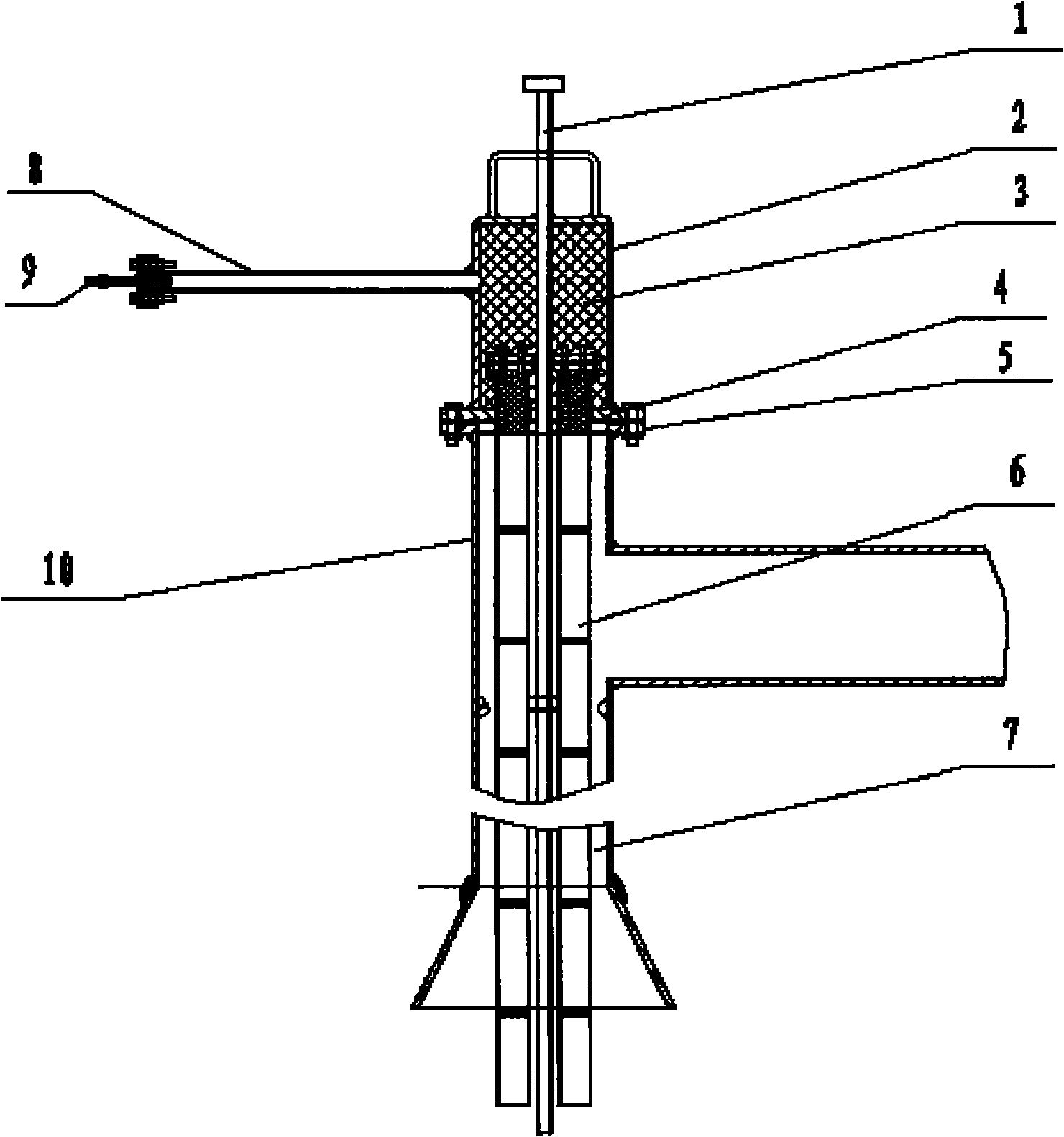

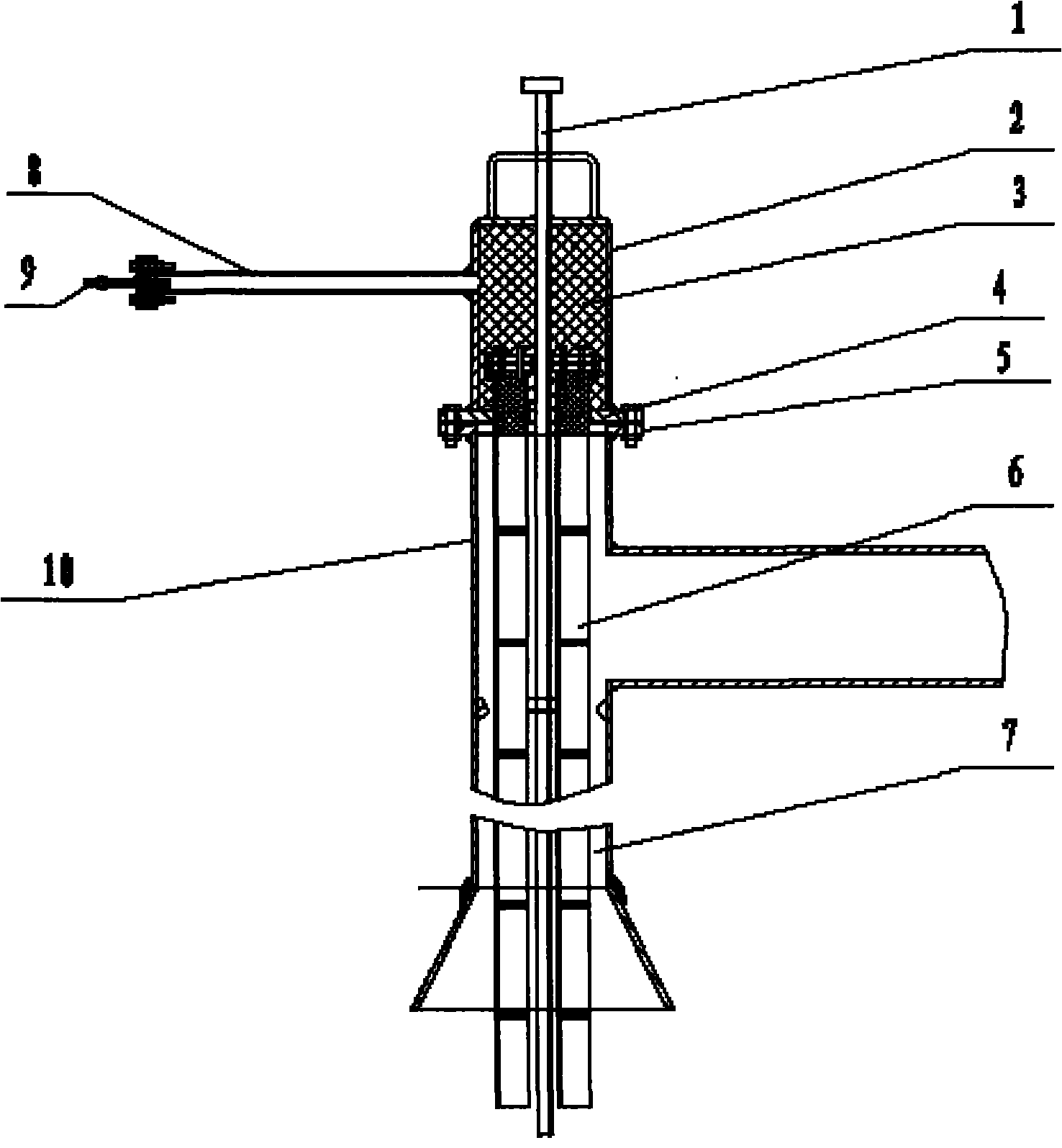

[0021] An anti-blocking pipe heating device for sponge titanium production of the present invention consists of a temperature measuring tube 1, a sleeve 2, a heat insulation layer 3, a sleeve flange 4, an inverted U-shaped connecting pipe flange 5, and a U-shaped resistor Wire 6, two heat radiation sleeves 7, conductive rod sleeves 8, conductive rods 9, and an inverted U-shaped connecting pipe 10, wherein the thermal radiation sleeve 7 is closed at the end, and is close to the inverted U-shaped connecting pipe flange 5 There is a small hole connected to the inverted U-shaped connecting pipe 10 at the position, and the diameter of the small hole is 10mm. The U-shaped resistance wire 6 is installed inside the heat radiation sleeve 7, and the temperature is controlled by the thermocouple in the temperature measuring tube 1. The resistance wire 6 The temperature can be 900-1100°C in the case of continuous power on. The U-shaped resistance wire 6 terminal is enclosed in the sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com