Lubricating oil additive based on single-layer or more-layer graphene

A lubricating oil additive, lubricating oil technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of difficult to disperse base oil, expensive carbon nanotubes, etc., achieve excellent stability and dispersibility, improve lubrication and anti-wear performance, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

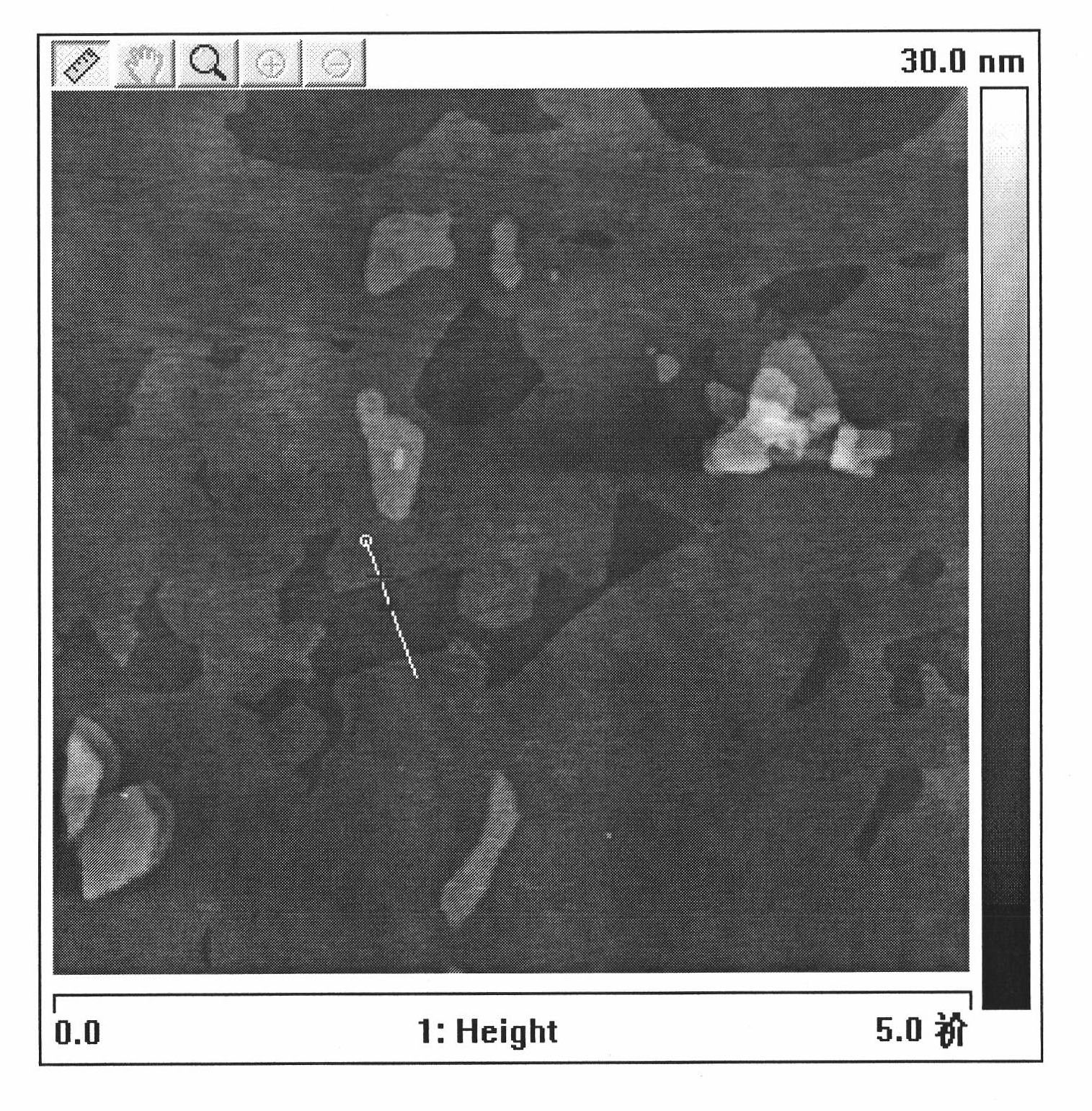

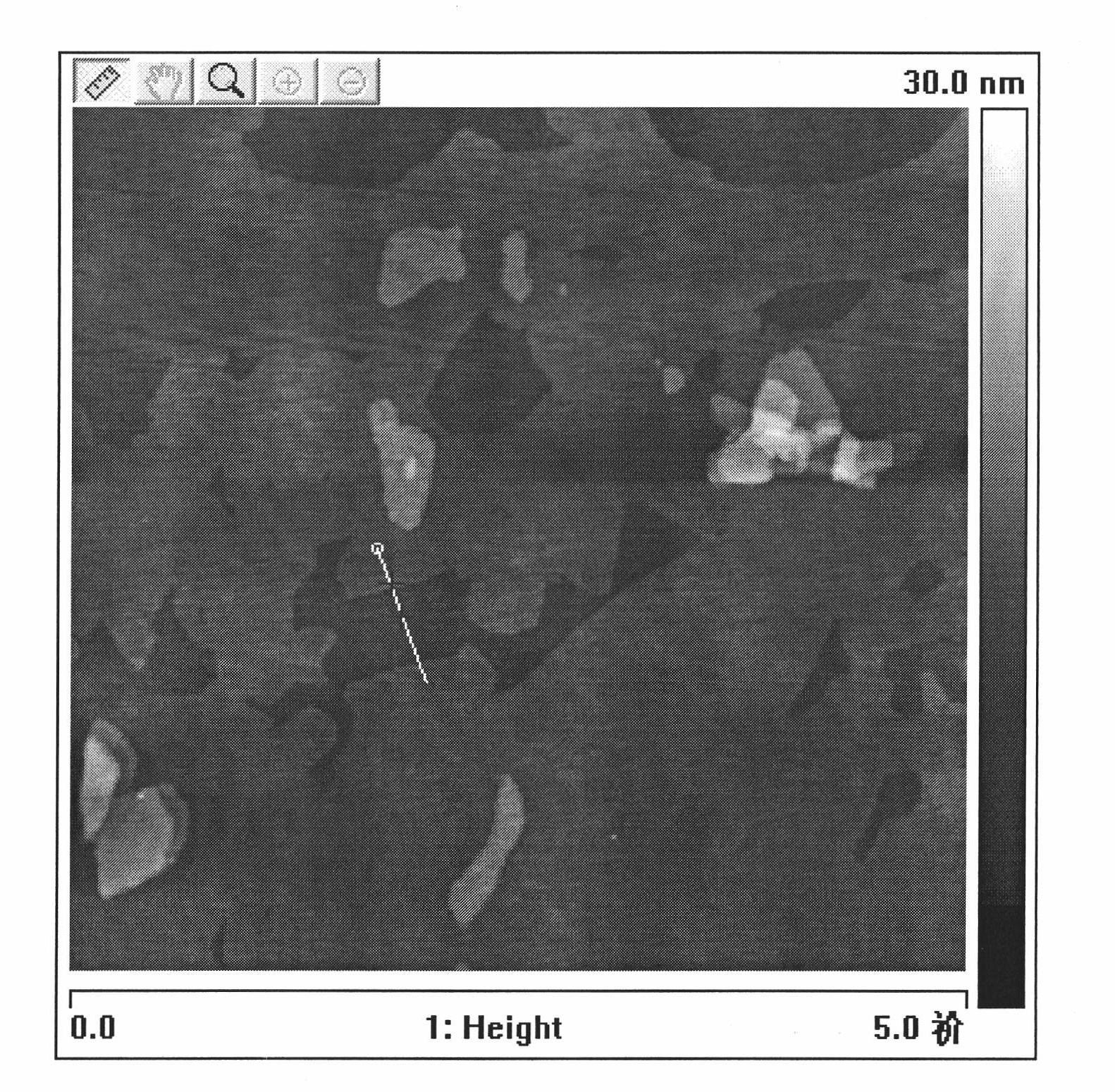

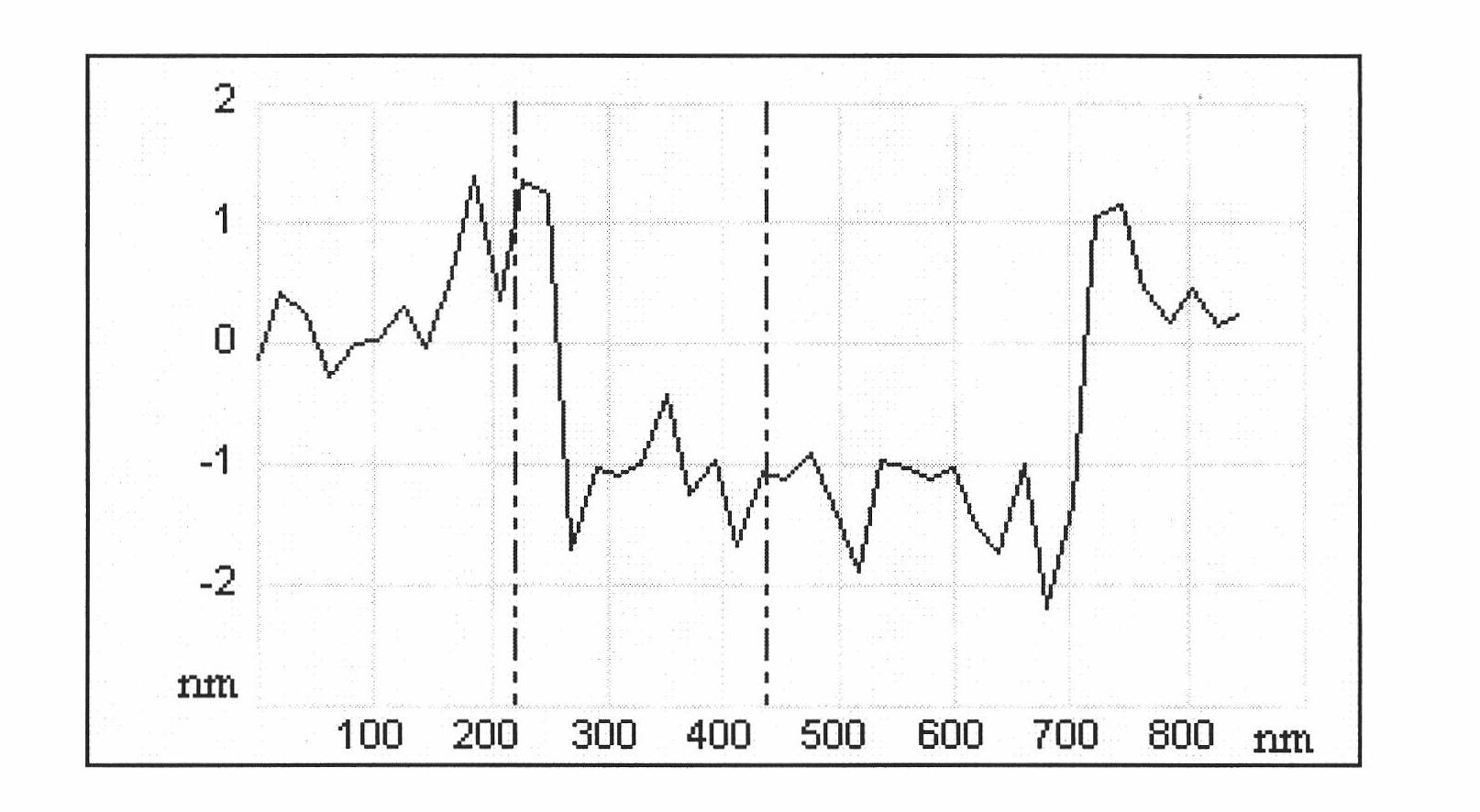

Image

Examples

Embodiment Construction

[0014] Below in conjunction with example, further illustrate the content of the present invention:

[0015] Case number one:

[0016] Preparation of graphene: using improved Hummer method in 98% concentrated sulfuric acid, low temperature cooling, adding natural flake graphite and NaNO during stirring 3 and KMnO 4 , the temperature of the reaction solution is controlled at 0 ~ 10 ° C, and the high temperature reaction is carried out after stirring for 5 hours. The temperature of the reaction solution does not exceed 100 ° C, and the stirring is continued for 30 minutes. The solution after the reaction is diluted with deionized water, and an appropriate amount of H is added. 2 O 2 , filter while hot, and wash the filtered product with deionized water until there is no SO in the filtrate 4 2- , then dried, ground and sieved, and then rapidly heat-treated at 1200 °C to obtain single-layer or several-layer graphene flakes.

[0017] According to mass percentage, 0.01% of singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com