Safety self-destructive syringe

A syringe and self-destruction technology, applied in the field of medical devices, can solve problems such as unsatisfactory effect, difficult manufacturing process, high material requirements, etc., and achieve the effects of low manufacturing process difficulty, easy promotion, and reduction of process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

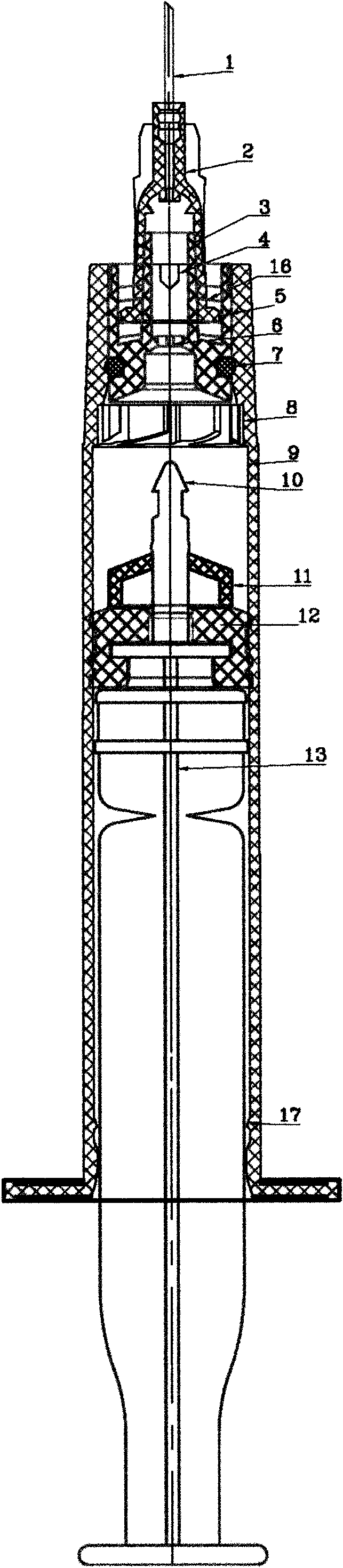

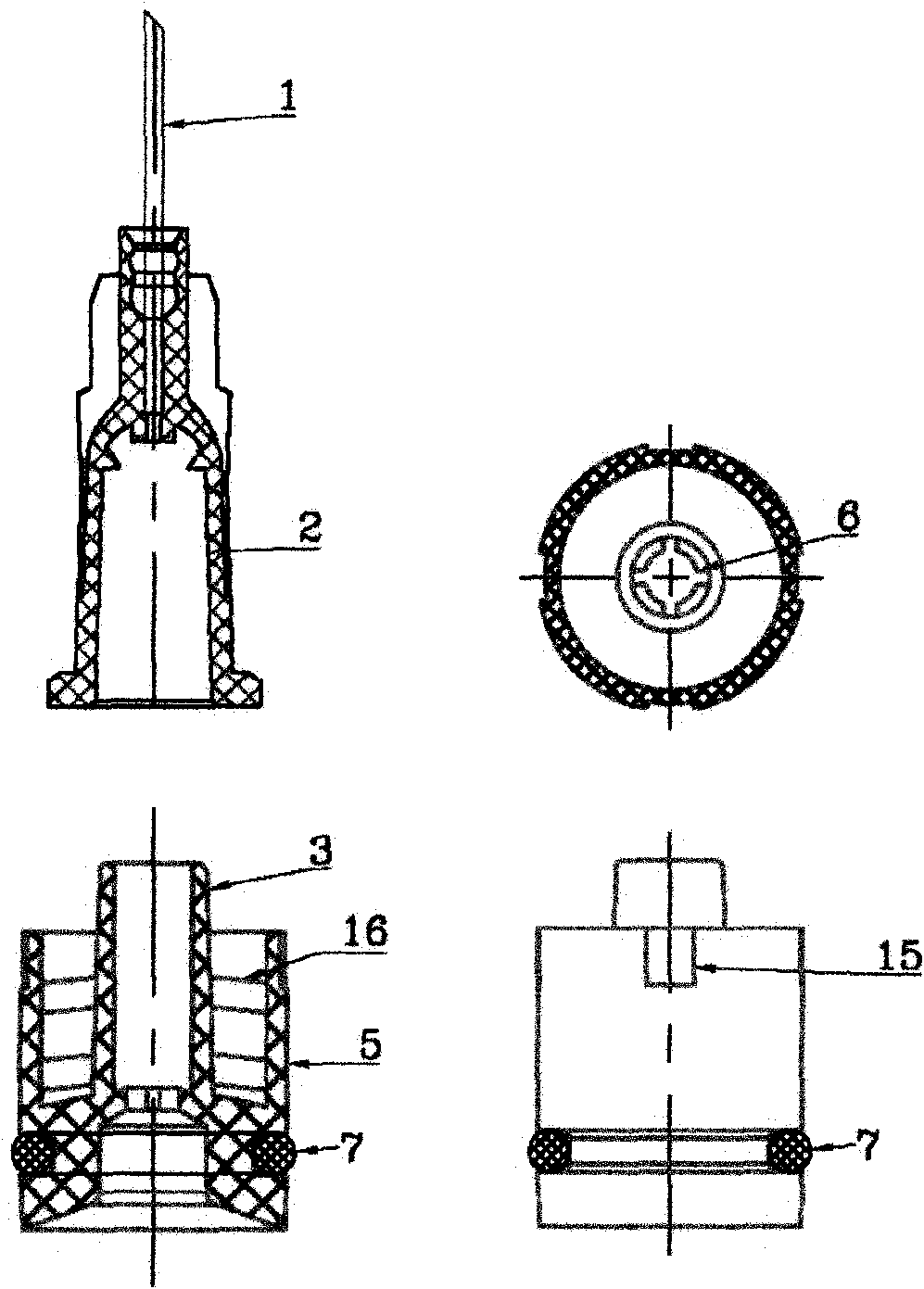

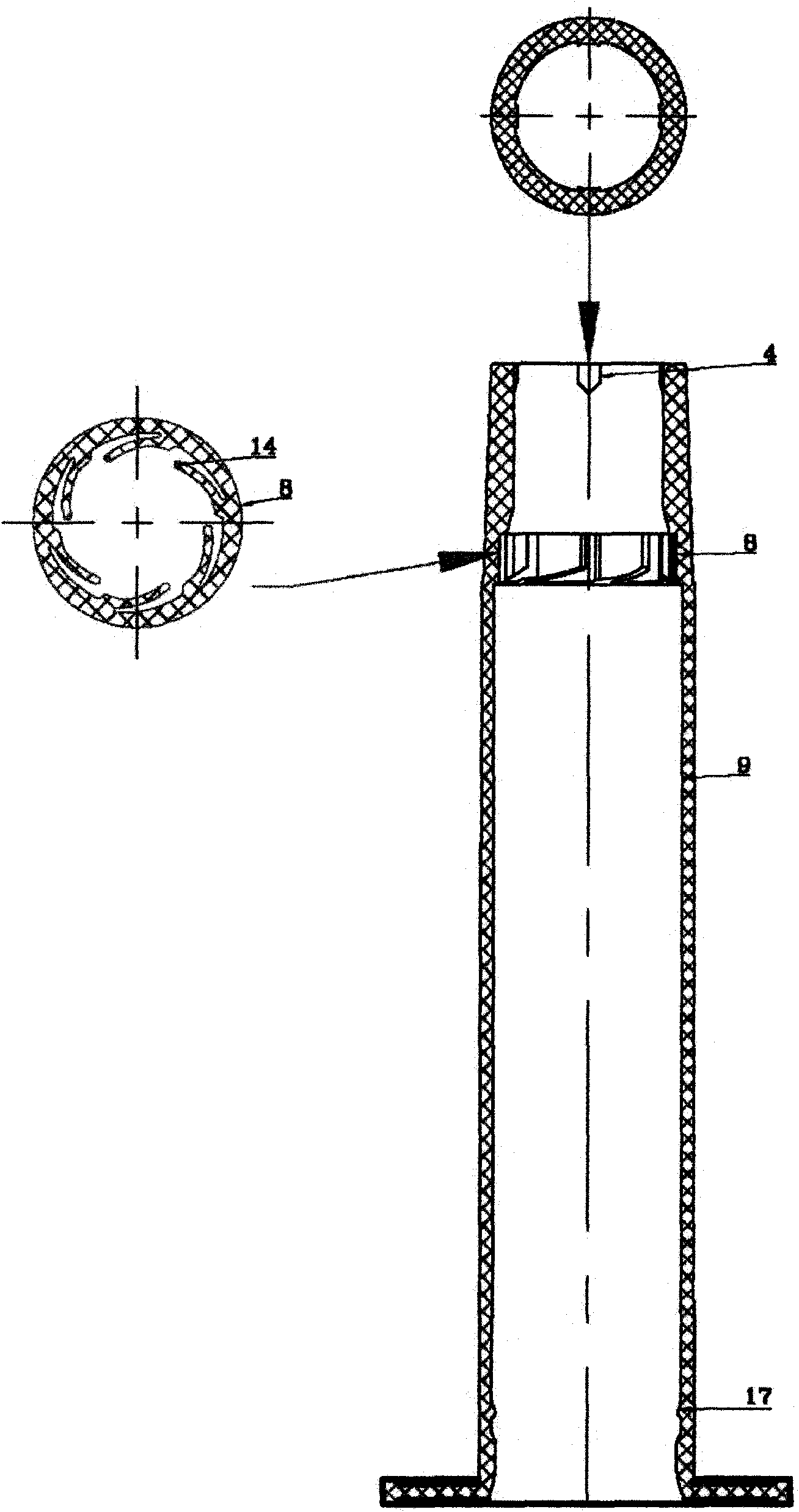

[0018] The patent will be further described below in conjunction with the drawings and embodiments.

[0019] As shown in Figure 1, Figure 2, Figure 3, Figure 4: The present invention mainly includes an injection needle (1); a needle seat (2); a 6:100 taper hole (3) on the replaceable needle seat; a barrel Fixed anti-skid strip (4) on the upper part; replaceable needle holder (5); pull-back tab (6) on the replaceable needle holder; seal ring (7); barrel neck (8); barrel (9); pull back Connecting post (10); Piston fixing seat (11); Piston (12); Core rod (13); Outer shrapnel (14); Fixed anti-skid groove (15) on the interchangeable needle seat; on the interchangeable needle seat The fixed thread (16); the core rod prevention ring (17) on the cylinder body; the threadless replaceable needle seat (18); the fixed needle needle seat (19), which is different from the prior art in that Description:

[0020] (1). The upper neck (8) of the cylinder (9) is provided with an external elastic pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com