Light-emitting device

A technology of light-emitting elements and light-emitting layers, applied in electrical components, light-emitting materials, electroluminescent light sources, etc., can solve the problems of lack, not bringing brightness and luminous efficiency, unable to achieve sufficient brightness and luminous efficiency, etc. Efficiency, the effect of expanding the recombination area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

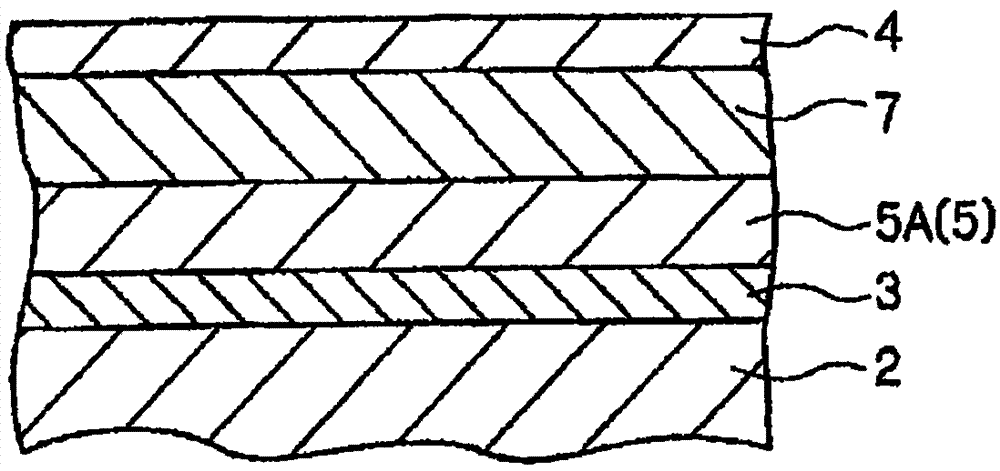

[0087] On a glass substrate, first, a thin film (thickness: 150 nm) of indium tin oxide (ITO) was formed by a sputtering method to form an anode. The substrate on which the anode was formed was cleaned and subjected to UV ozone treatment. Then, in the air, a polyethylenedioxythiophene-polystyrenesulfonate (abbreviation: "PEDOT-PSS") coating solution was applied on the ITO film by spin coating, and dried to form a hollow film. Hole injection layer (thickness: 20 nm).

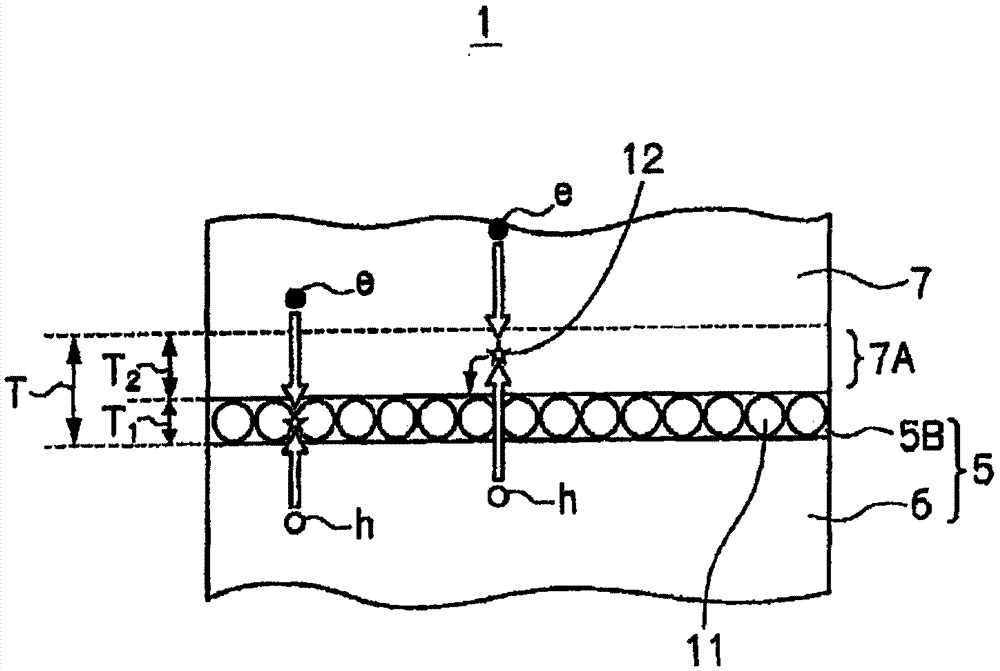

[0088] Next, N,N-diphenyl-N,N-di( 3-methylphenyl)-1,1-biphenyl-4,4-diamine (TPD) and quantum dots (manufactured by Evident Technologies, core: CdSe, shell: ZnS, emission wavelength: 520nm) mixed with toluene The mixed solution was spin-coated on the hole injection layer to form a hole transport layer and a light emitting layer (total thickness: 40 nm). The hole transport layer and light-emitting layer are separated from the quantum dots of TPD, and the light-emitting layer composed of quantum dots is formed as...

Embodiment 2

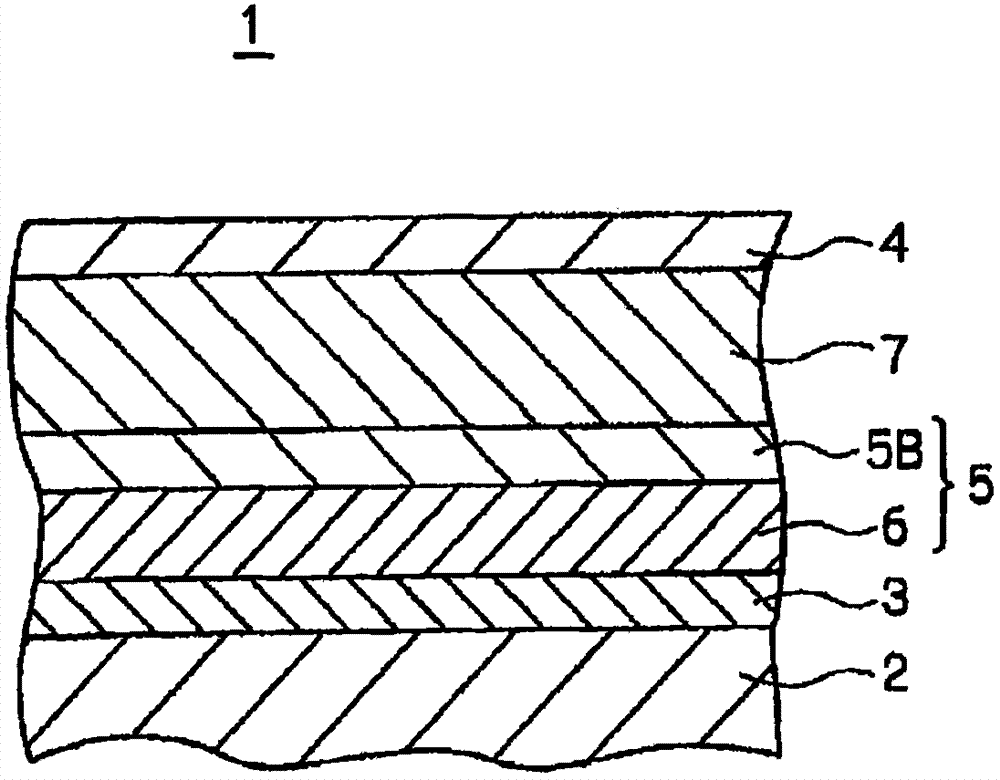

[0096] In Example 1, the hole-transporting layer and the light-emitting layer are formed simultaneously by applying a mixed solution of TPD and quantum dots with a mixing ratio of 9:5 on the hole-injecting layer, and then forming a 60nm-thick layer composed of BAlq2. The light-emitting element of Example 2 was produced in the same manner as in Example 1 except that the electron transport layer composed of BAlq2 was replaced with the electron transport layer.

Embodiment 3

[0098] In Example 2, the light-emitting element of Example 3 was produced in the same manner as in Example 2 except that the thickness of the electron transport layer composed of BAlq2 was changed to 40 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com