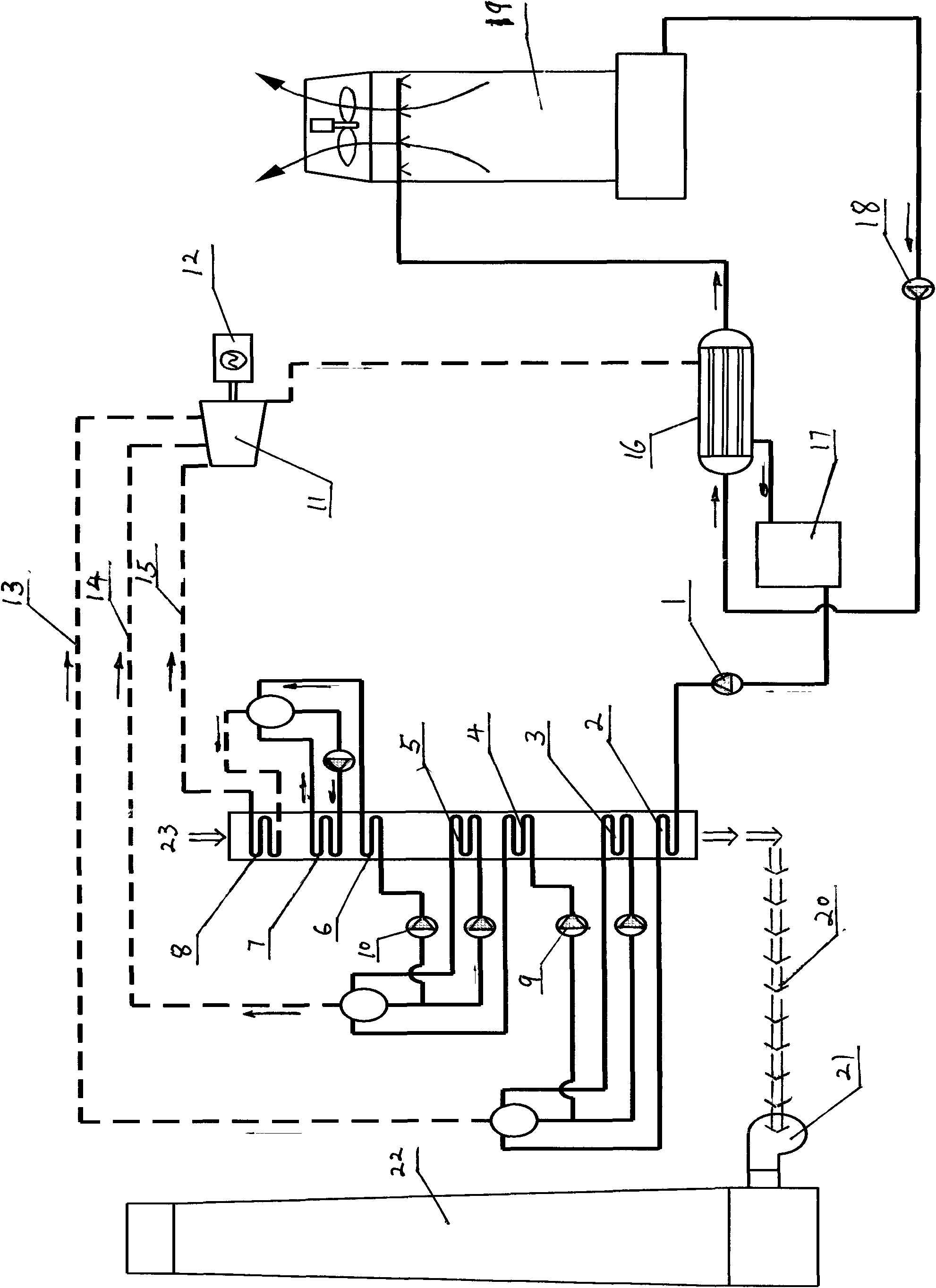

Multistage evaporation organic Rankine cycle waste heat recovery generation system and method thereof

A power generation system and waste heat recovery technology, applied in the fields of resources and environment, can solve the problems of reduced energy utilization, low power cycle efficiency, environmental thermal pollution, etc., and achieve the effects of reducing discharge temperature, improving thermal efficiency, and improving benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: For example, in a sinter cooling process of Kunming Iron and Steel Company, air cooling sinter is adopted, resulting in waste gas emission at about 350°C-400°C (flow rate is about 6x10 5 N m 3 / h), the conventional waste heat recovery power generation system using water as the working medium is now installed, which can obtain a net power generation capacity of 5000Kw, and the annual recoverable electricity is about 2.3x10 7 Kw.h, equivalent to an electricity price of 9.2 million yuan. After adopting the new technology of multi-stage evaporation organic Rankine cycle, the circulating working medium is n-hexane, three-stage evaporation, the evaporation pressure of the low-pressure stage is 1.41bar, and the corresponding evaporation temperature is 80°C. The evaporation pressure of the first stage is 7.44bar, and the corresponding evaporation temperature is 150°C. The evaporation pressure of the high-pressure stage is 24.2bar, and the corresponding evaporation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com