Isothermal pressure-changing secondary refining process for preparing high-quality silkworm chrysalis oil by using reeling silk leftover silkworm chrysalises

A technology for silkworm chrysalis oil and leftovers, which is applied in the directions of fat oil/fat refining, fat oil/fat production, and fat generation, etc., can solve problems such as difficult removal, strong fishy smell, restricting silkworm chrysalis and silkworm chrysalis oil processing and utilization, etc., so as to delay aging. , the effect of preventing atherosclerosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

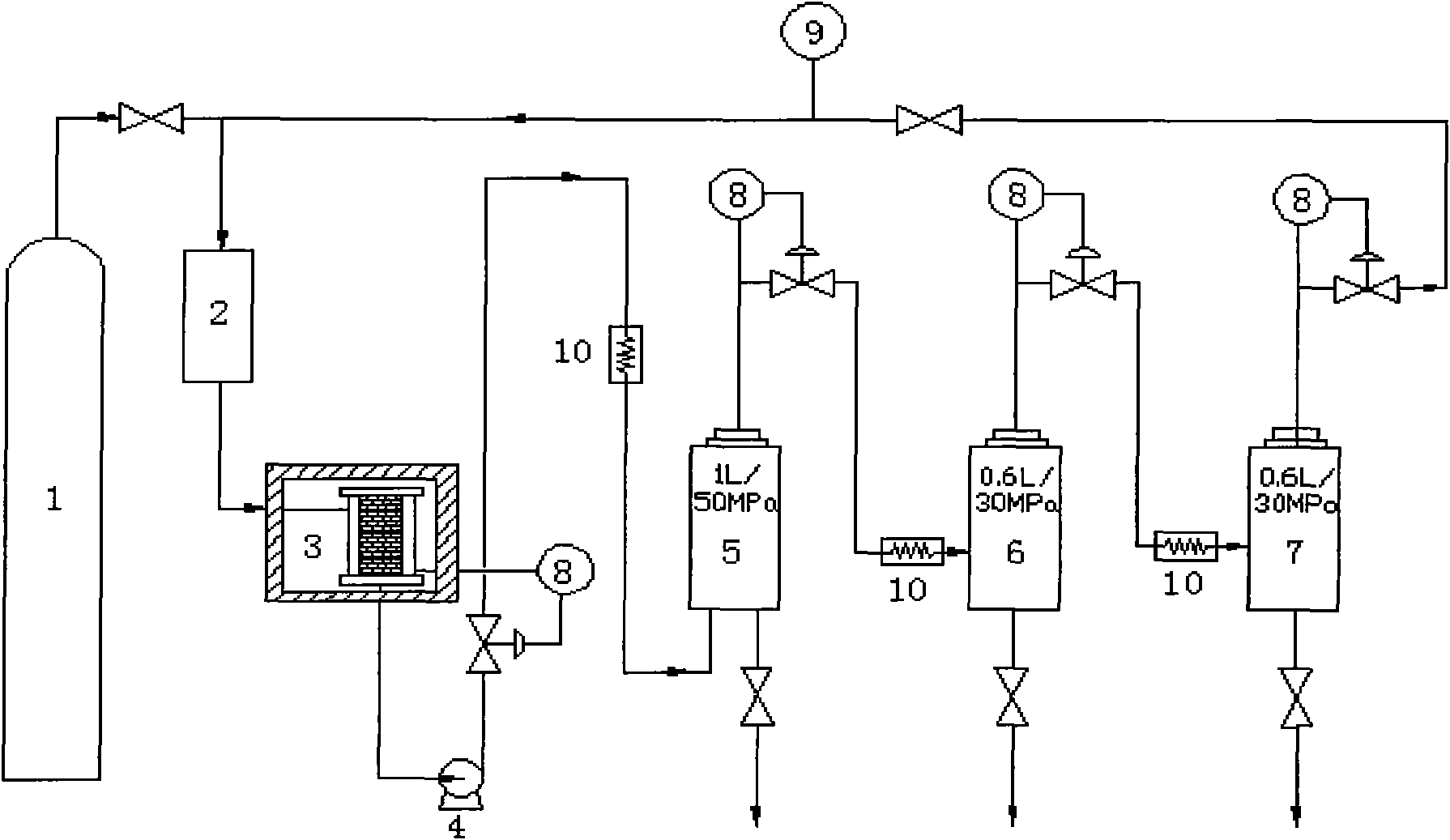

[0033] see figure 1 , (CO2 steel cylinder 1, purifier 2, cold box 3, pump 4, extraction kettle 5, separation kettle I 6, separation kettle II 7, pressure gauge 8, flow meter 9, preheater 10) retrieved from the silk reeling factory The leftover silkworm chrysalis is selected to remove impurities, dried for a certain period of time in an electric heating constant temperature blast drying oven at about 60°C, so that the moisture content is about 3%-10%, and crushed through a 20-mesh sieve. Weigh about 200g of silkworm chrysalis powder, put it in the extraction kettle, open the carbon dioxide cylinder, and open the HA121-50-O1-C supercritical CO 2 A series of valves on the fluid extraction equipment allow carbon dioxide to flow through the extraction tank, separation tank I, and separation tank II to form a loop; the temperature of the extraction tank, the temperature of the separation tank I and the temperature of the separation tank II respectively reach the set 30-50°C , 40-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com