Multi-scale wavelet antivibration design method of high-speed main shaft of machine tool

A technology of high-speed spindle and design method, which is applied in the direction of metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention are described in further detail below in conjunction with accompanying drawing:

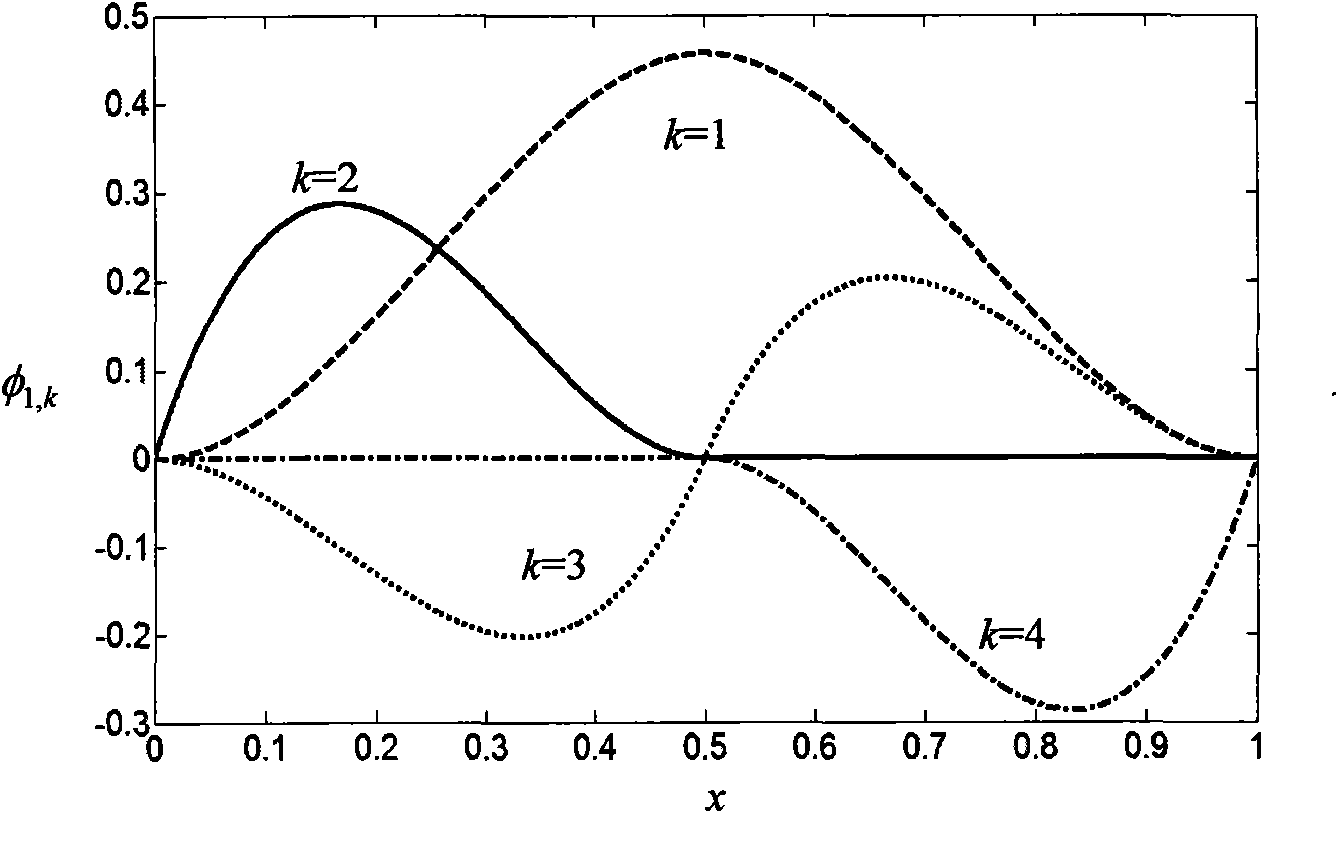

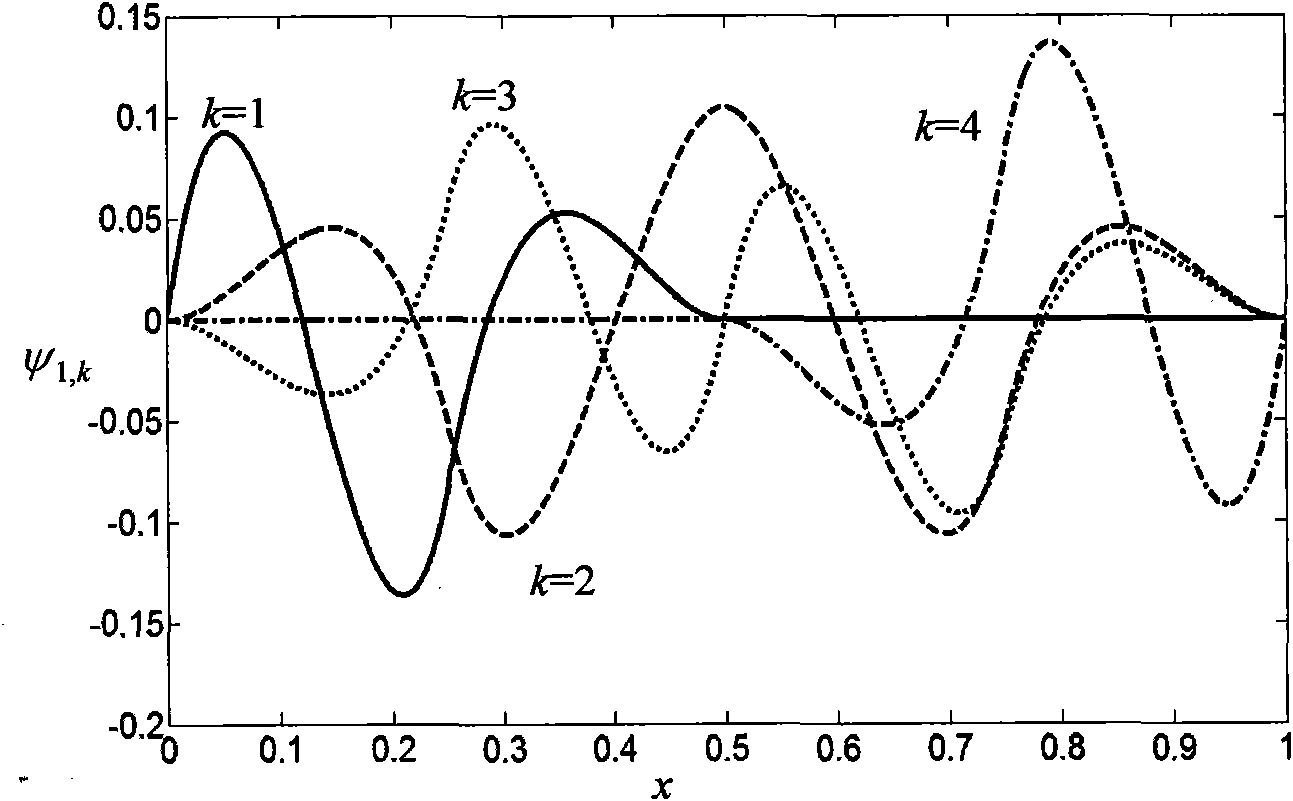

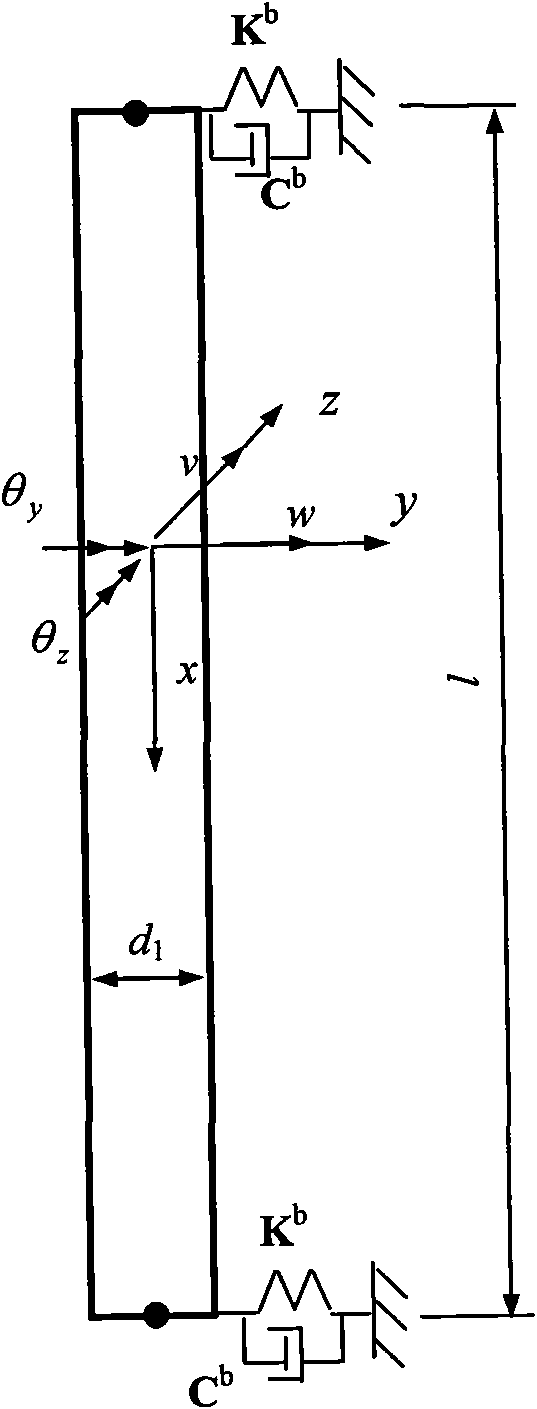

[0056] In the first step, the interval cubic Hermitian spline wavelet is used as the multi-scale interpolation base, and the comprehensive consideration of gyro torque, transverse shear deformation, spindle moment of inertia, material hysteresis and viscous damping, bearing cross stiffness and cross damping is established. The multi-scale wavelet numerical solution model, including the following steps:

[0057] I. Establish a single-scale interval cubic Hermitian spline wavelet numerical solution model for the analysis of the dynamic characteristics of the high-speed spindle of the machine tool.

[0058] The classical wavelet function is a square-integrable real number space L defined on the entire real number axis R or a periodic function 2 The complete basis on (R), when solving the boundary value problem, there will be numerical oscillation on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com