Triple effect seven-stroke falling film evaporator

A falling film evaporator, three-effect evaporation technology, applied in the direction of multi-effect evaporation, can solve the problem of difficult control of heating temperature, and achieve the effect of saving energy consumption, consumption and operating costs, and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

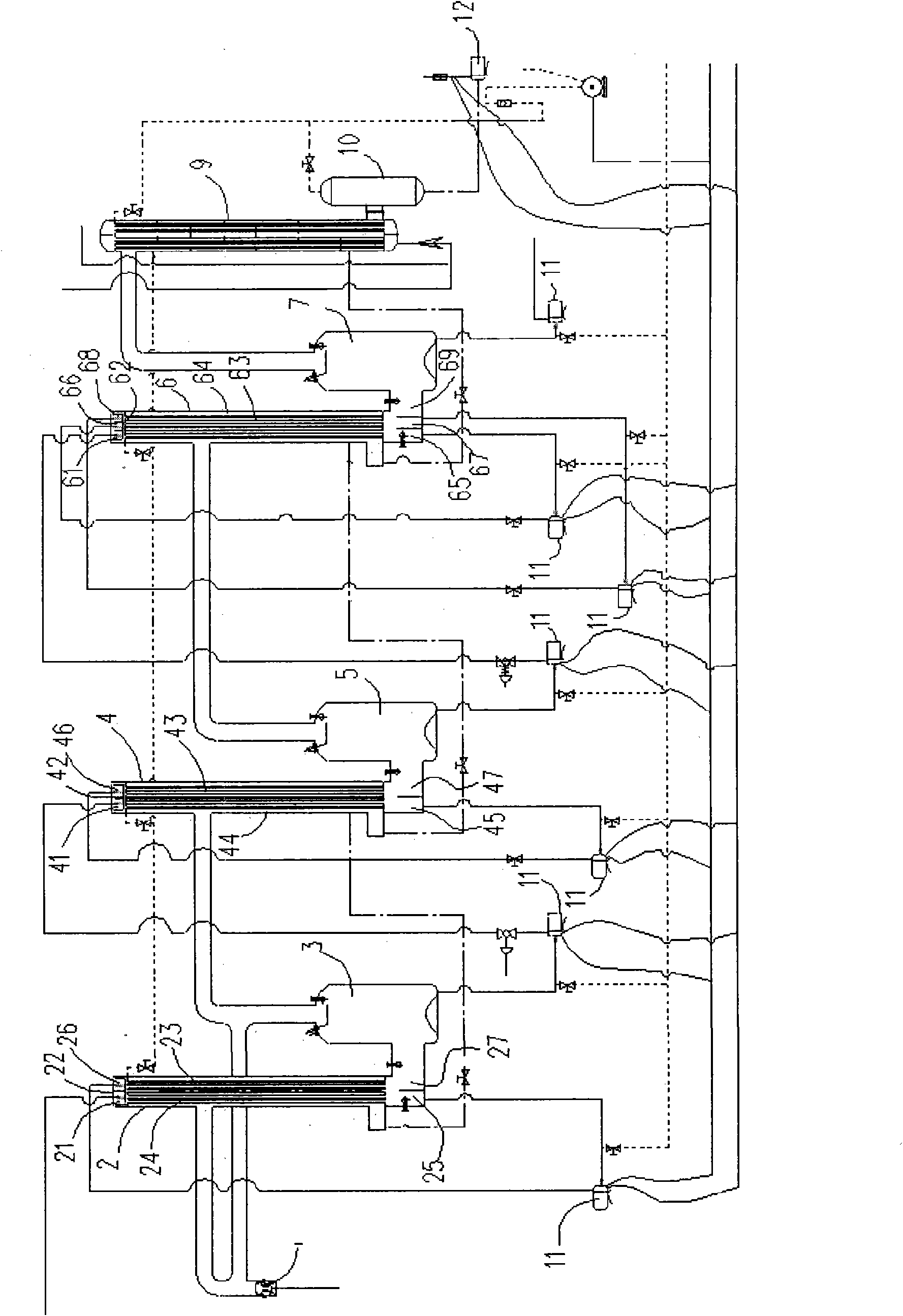

[0042] like figure 1 Shown is an overall schematic diagram of an implementation of the three-effect seven-stroke falling film evaporator of this embodiment.

[0043] like figure 2 Shown is a schematic diagram of the feeding chamber of the first-effect heating chamber, the feeding chamber of the first-effect heating chamber is divided into a first feeding chamber 21 of one effect and a second feeding chamber of one effect by the vertical plate 22 arranged above the material distributor 8 26. The separation method of the first-effect discharge chamber and other effect feed chambers and discharge chambers is similar to this; the various effect feed chambers mentioned in the text refer to the first-effect feed chamber, the second-effect feed chamber and the three-effect feed chamber. Material chamber....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com