Rotating armature controller

A technology for rotating electrical machines and control devices, applied in control devices, motor generator control, AC motor control, etc., can solve the problems of increased electromagnetic noise, stronger electric field noise, and large energization current, and achieves noise reduction and conversion. The effect of reduced frequency and reduced likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

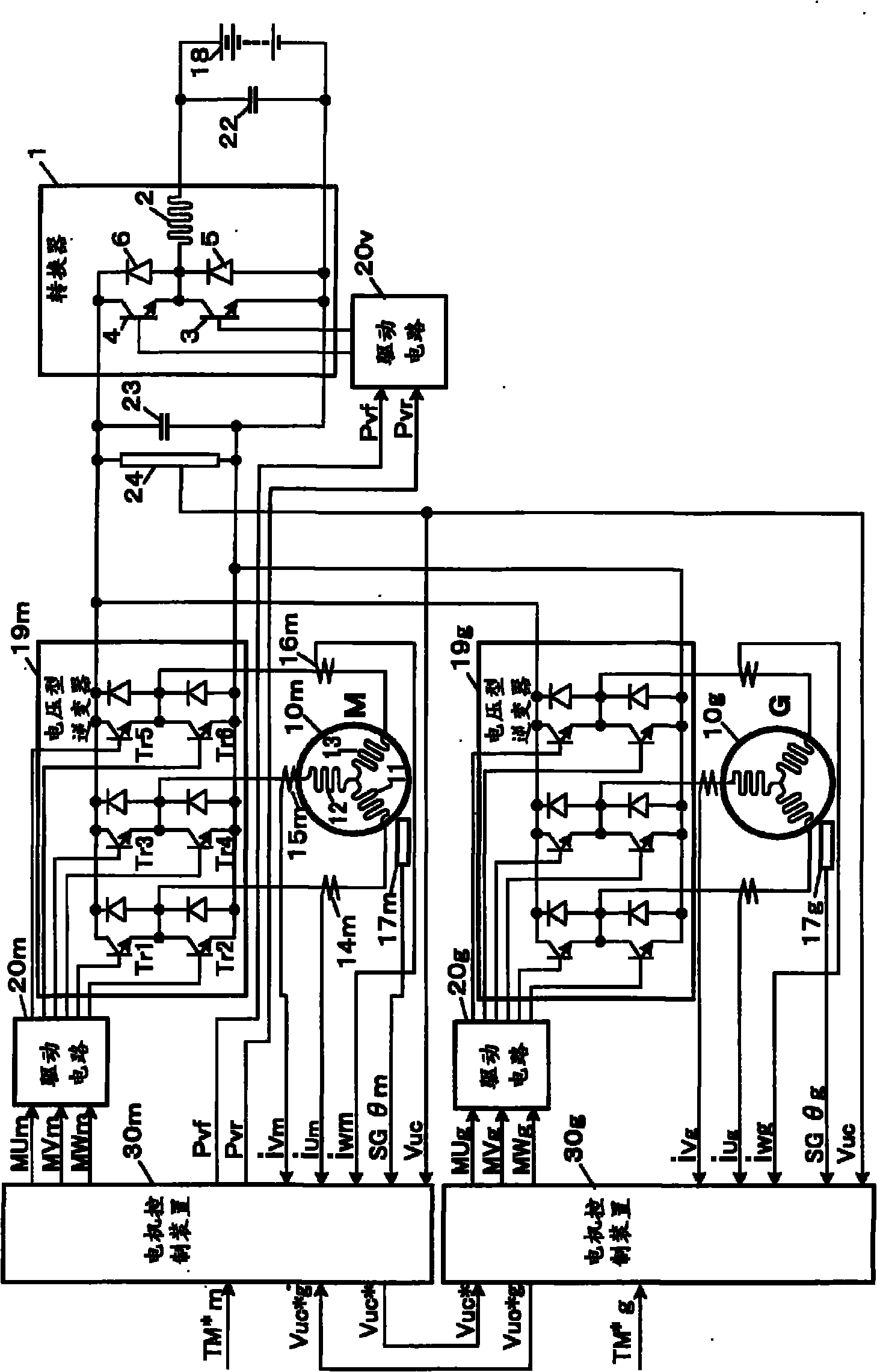

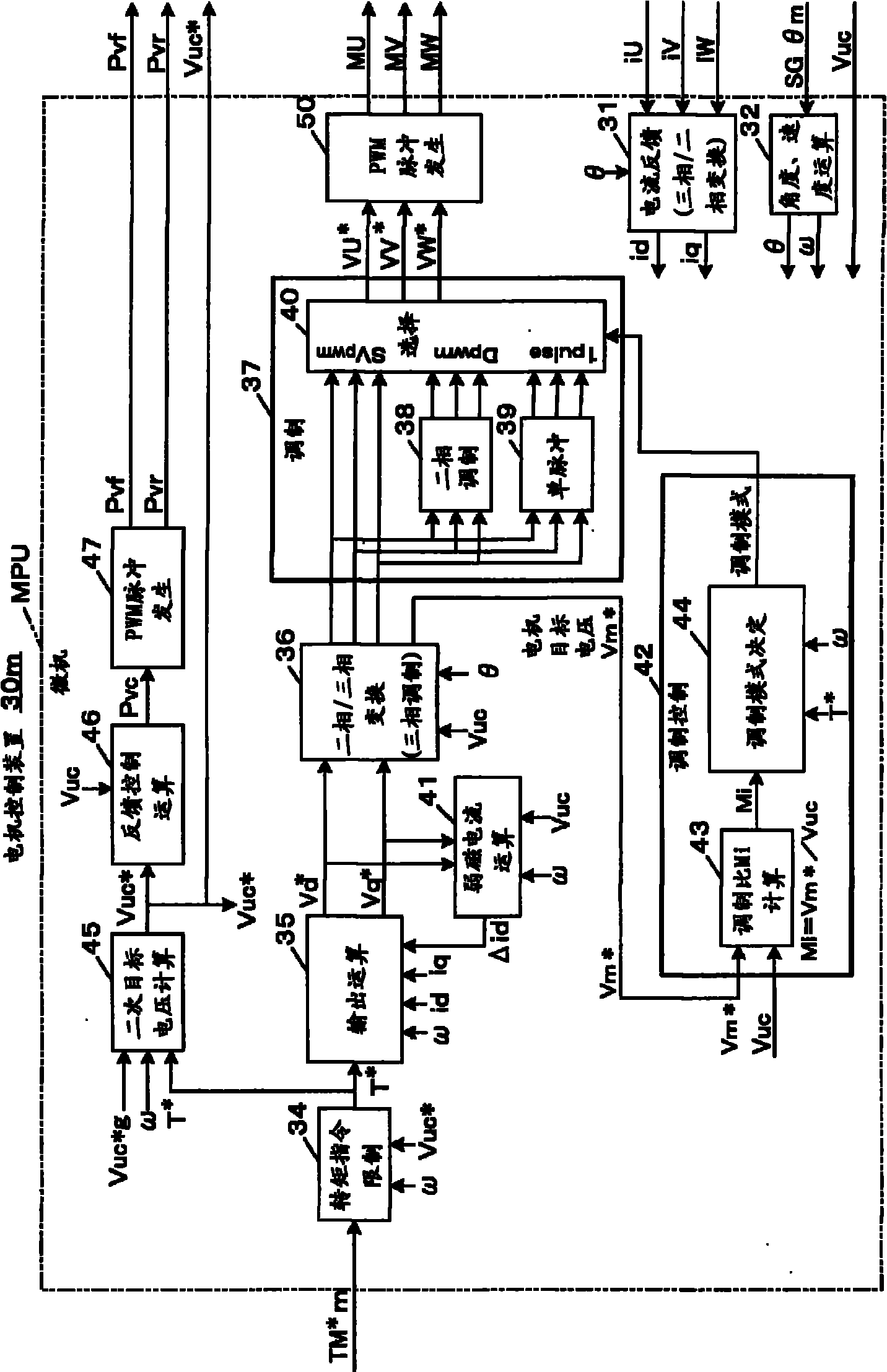

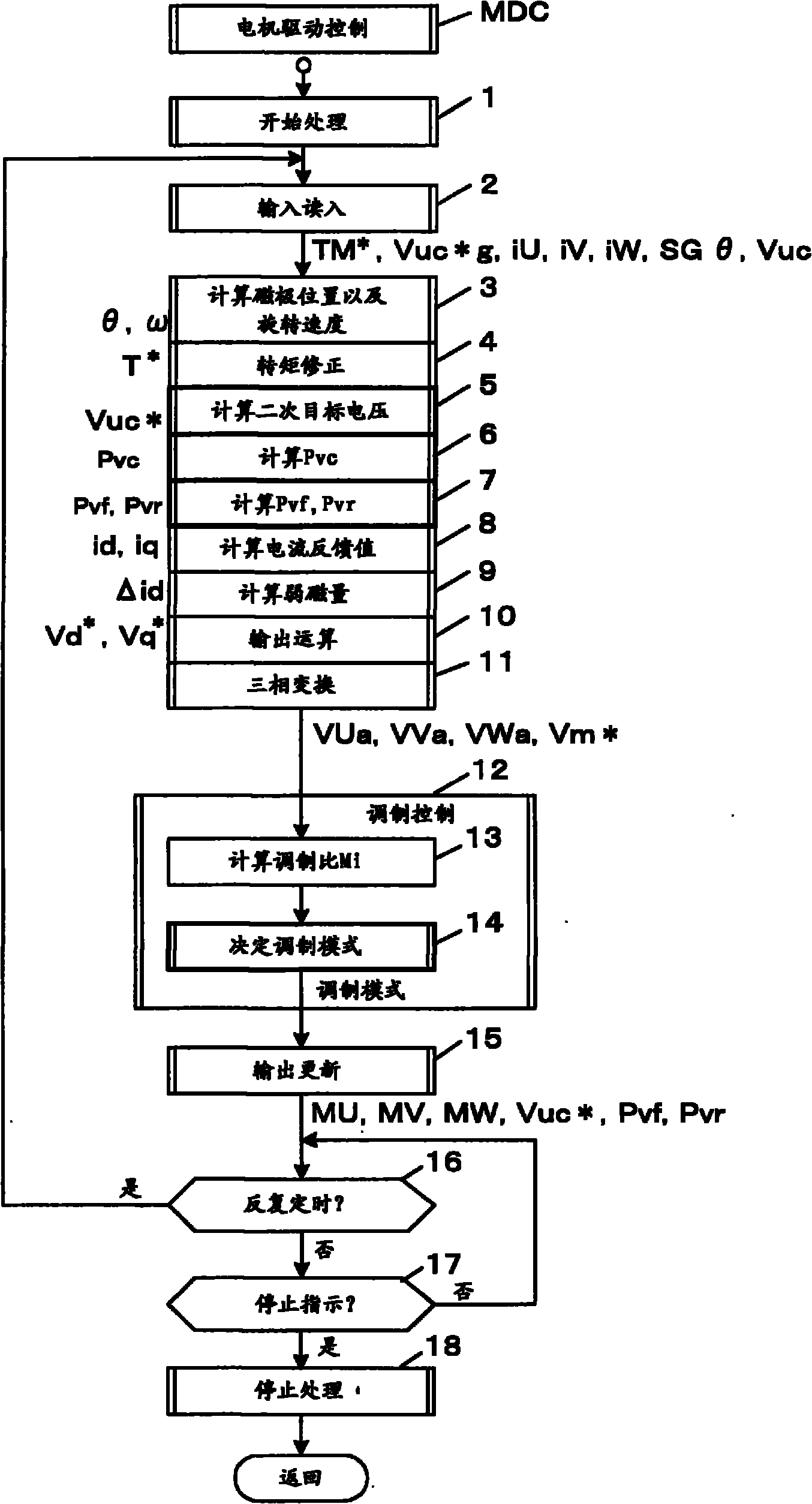

[0075] figure 1 The outline of the first embodiment of the present invention is shown. The motor (electric motor) 10m, which is the first rotating electrical machine to be controlled, is a permanent magnet type synchronous motor mounted on a vehicle for rotationally driving wheels in this embodiment. A permanent magnet is built into the rotor and a stator has a Three-phase coils 11 to 13 of U-phase, V-phase, and W-phase. The voltage source inverter 19m as the first inverter supplies electric power of the battery 18 on the vehicle to the motor 10m. A rotor of a first resolver 17m for detecting the rotor magnetic pole position is connected to the rotor of the motor 10m. The resolver 17m generates an analog voltage (rotation angle signal) SGθm representing its rotor rotation angle, and supplies it to the motor control device 30m.

[0076] The primary side capacitor 22 is connected to the battery 18 which is a storage battery on the vehicle when the electric device on the vehi...

no. 2 Embodiment

[0129] Figure 5 The outline of the second embodiment of the present invention is shown in . The rotating electric machine (motor) 10m that is the control object is a permanent magnet synchronous motor mounted on a vehicle for rotationally driving the wheels in this embodiment. A permanent magnet is built into the rotor, and a U phase, V phase, and V phase are provided on the stator. Phase and W-phase three-phase coils 11 to 13 . The voltage source inverter 19m as the first inverter supplies electric power of the battery 18 on the vehicle to the motor 10m. The rotor of the first resolver 17m for detecting the rotor magnetic pole position is connected to the rotor of the motor 10m. The resolver 17m generates an analog voltage (rotation angle signal) SGθm representing its rotor rotation angle, and supplies it to the motor control device 30m.

[0130] In the second embodiment, since the battery voltage Vdc is applied to the inverter instead of the converter for boosting and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com