Resin composition for light diffusion plate, light diffusion plate and method for producing the same

A technology of resin composition and light diffusion plate, applied in optics, applications, optical components, etc., can solve the problems of small transmittance, unevenness, low hygroscopicity, etc., and achieve low water absorption, high productivity, and high usefulness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0103] The present invention will be described more specifically with examples below. The present invention should of course not be limited by the scope of these examples. Unless otherwise stated, the following "parts" and "%" are mass standards.

[0104] Description of the measurement method used

[0105] GPC Determination Conditions for Multi-branched Macromonomers

[0106] GPC measurement of multi-branched macromonomers was carried out under the following conditions: high performance liquid chromatography (HLC-8220GPC manufactured by Tosoh Corporation), RI detector, TSK gelG6000H×1+G5000H×1+G4000H×1+ G3000H×1+TSK guard column H×1, solvent THF, flow rate 1.0ml / min, temperature 40°C.

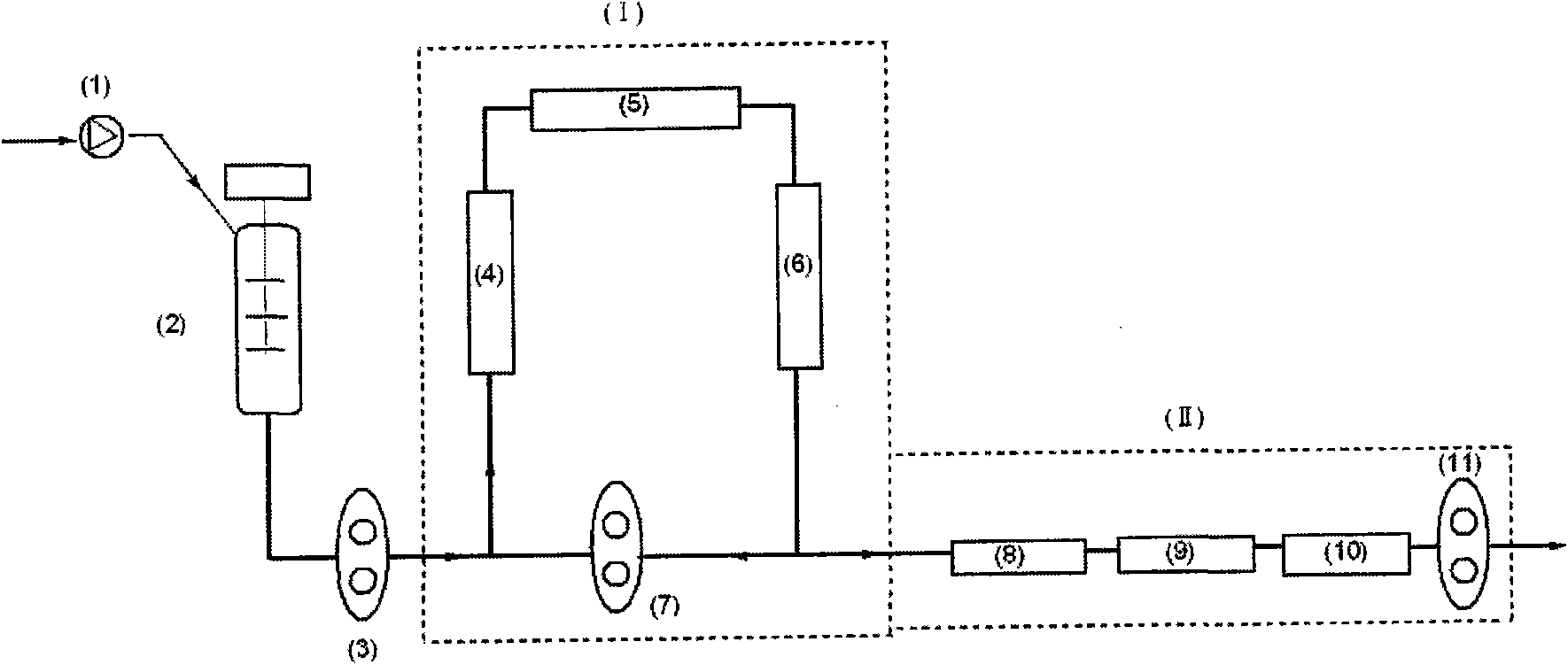

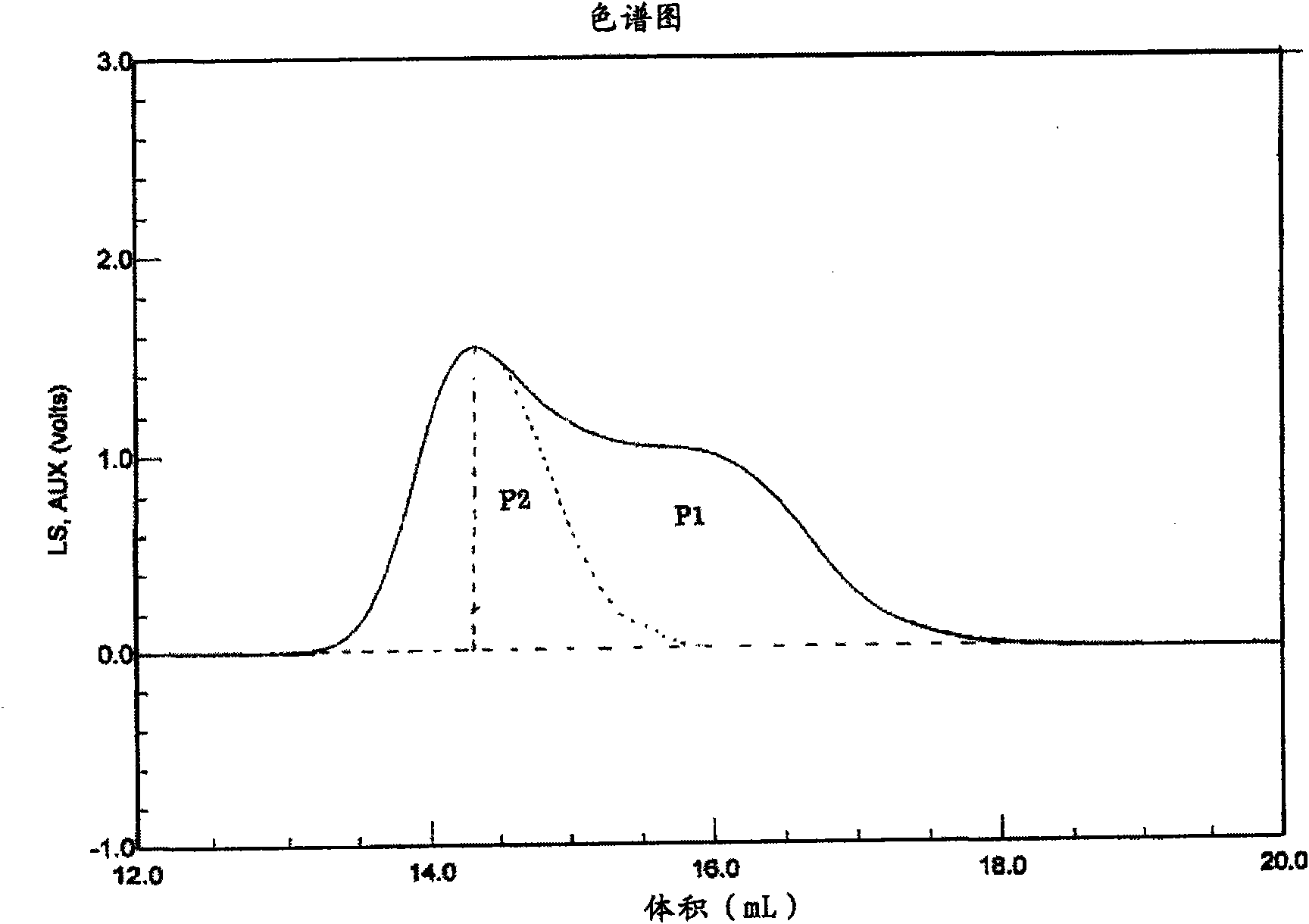

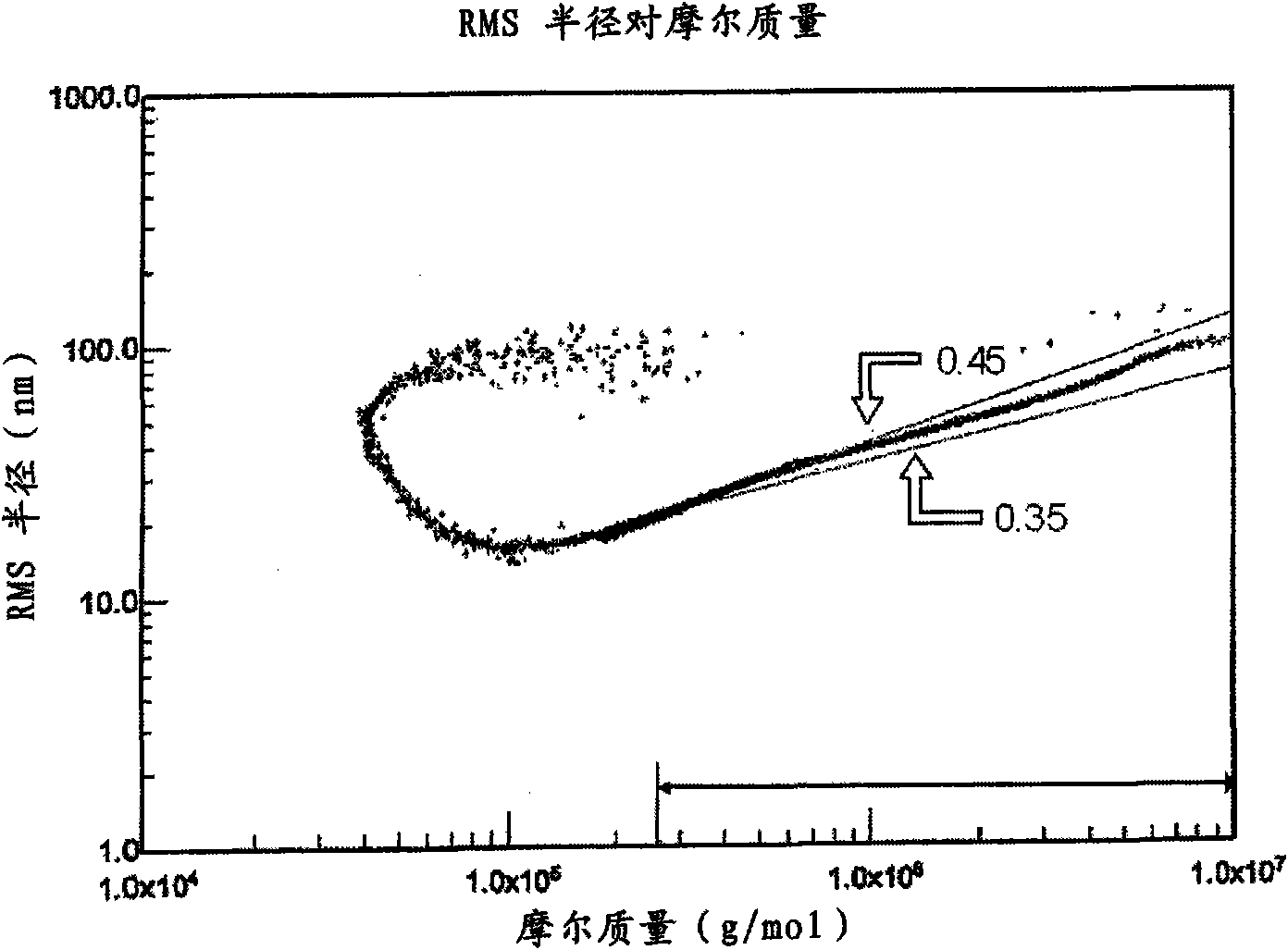

[0107] GPC-MALS determination

[0108] Carry out the GPC-MALS determination of styrene-based resin under the following conditions: Shodex HPLC, detector Wyatt Technology DAWN EOS, Shodex RI-101, chromatographic column Shodex KF-806L × 2, solvent THF, The flow rate is 1.0ml / min. In additio...

reference example 1

[0123] Synthesis of reference example 1 multi-branched macromonomer (Mm-1)

[0124] In a 1000-ml eggplant-shaped flask equipped with a stirring device, dropping funnel, thermometer, nitrogen gas introduction device, and bubbler, dissolve 4-bromobis(ethyleneoxy)phenylacetonitrile 35 in dimethyl sulfoxide under a nitrogen atmosphere. (DMSO). After making the inner temperature of the water bath 30° C., 44 ml of 50% sodium hydroxide aqueous solution was dropped over 3 minutes. The mixture was kept at 30° C. and stirred for 2 hours to obtain a precursor of a highly branched macromonomer. Further, 50.0 g of 4-chloromethylstyrene was dripped into the reactant and stirred for 2 hours to obtain a solution of a highly branched macromonomer.

[0125] The obtained solution was filtered to remove solid matter, and the filtrate was poured into 5 L of methanol containing 225 ml of a 5 mol / L aqueous hydrochloric acid solution to precipitate a multi-branched macromonomer. The multi-branched...

reference example 2

[0127] Synthesis of reference example 2 multi-branched macromonomer (Mm-2)

[0128]

[0129] In a 2L flask equipped with a stirrer, a thermometer, a dropping funnel, and a condenser, at room temperature, add 50.5 g of ethoxylated pentaerythritol (5 mole-ethylene oxide addition pentaerythritol), BF 3 Diethyl ether solution (50%) 1g, heated to 110°C. While controlling the heat generation of the reaction, 450 g of 3-ethyl-3-(hydroxymethyl)oxetane was slowly added thereto over 25 minutes. After the end of the exotherm, the reaction mixture was further stirred at 120°C for 3 hours, after which it was cooled to room temperature. The obtained highly branched polyether polyol had a weight average molecular weight of 3,000 and a hydroxyl value of 530.

[0130] Synthesis of multi-branched macromonomers with methacryloyl and acetyl groups

[0131]Into a reactor equipped with a stirrer, a thermometer, a Dean Stark Decanter equipped with a condenser, and a gas introduction pipe, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com