Ornament parts

A technology for decorative parts and substrates, applied in the field of decorative parts, can solve the problems of unreached film peeling, corrosion, low brightness, etc., and achieve the effect of color tone improvement, beautiful color tone, and lightness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

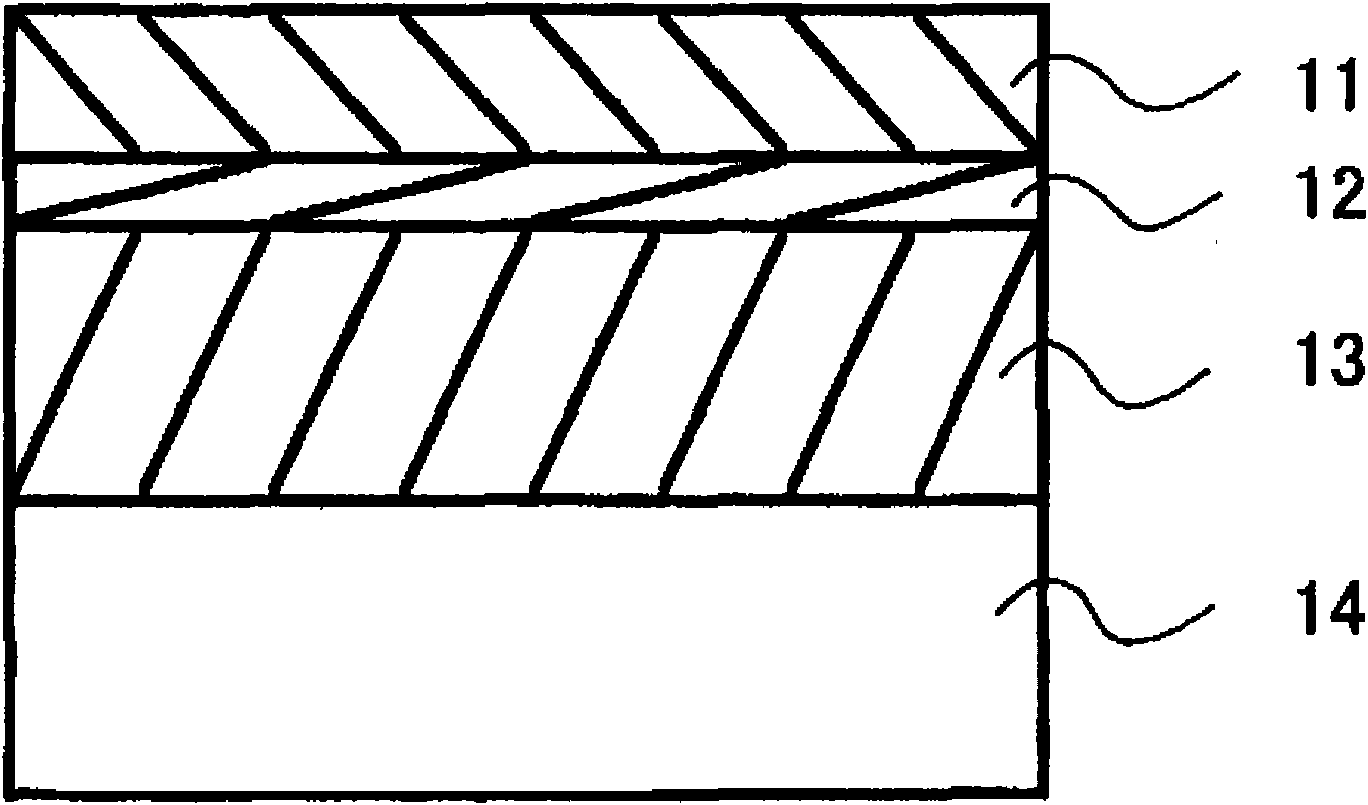

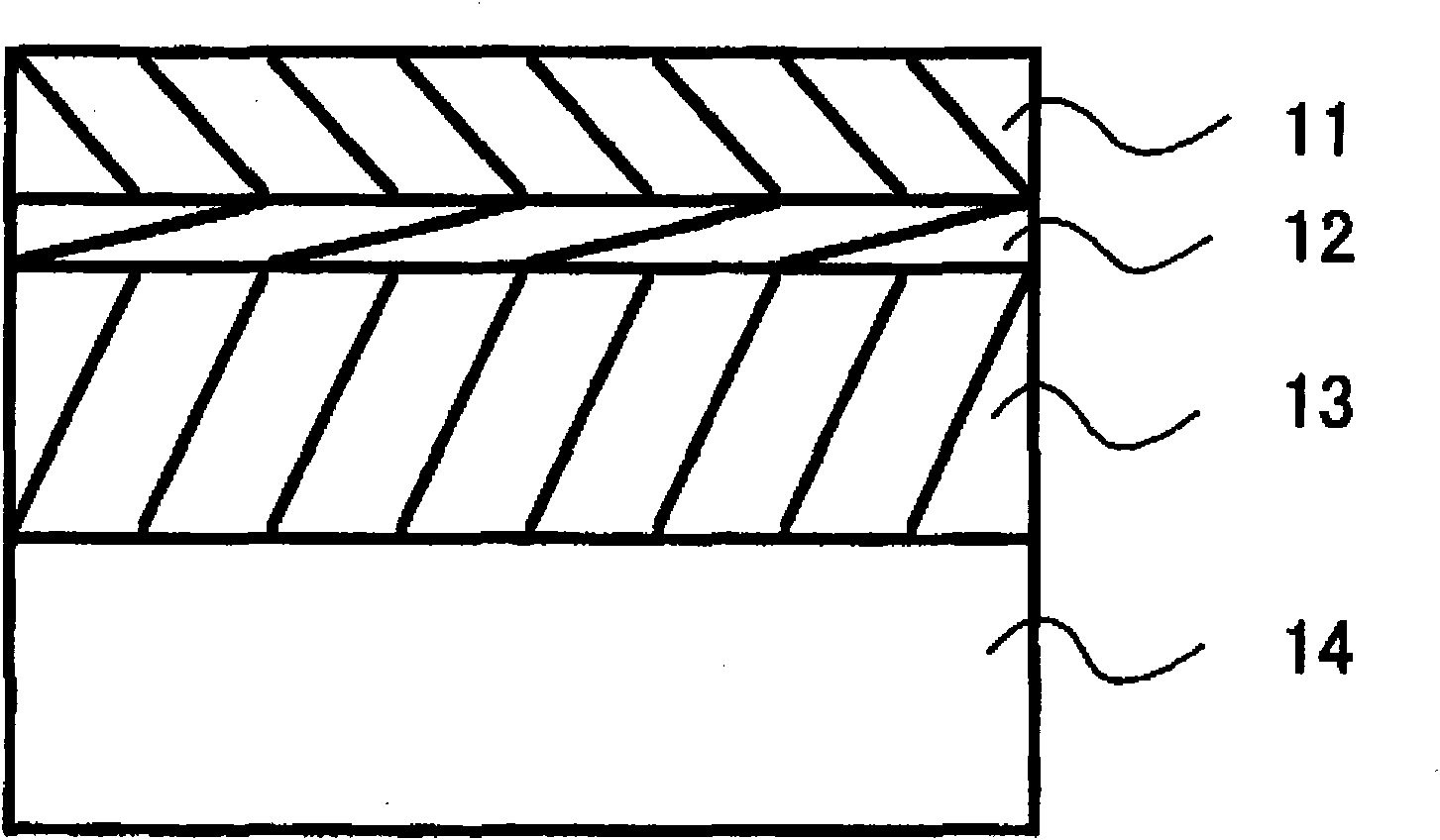

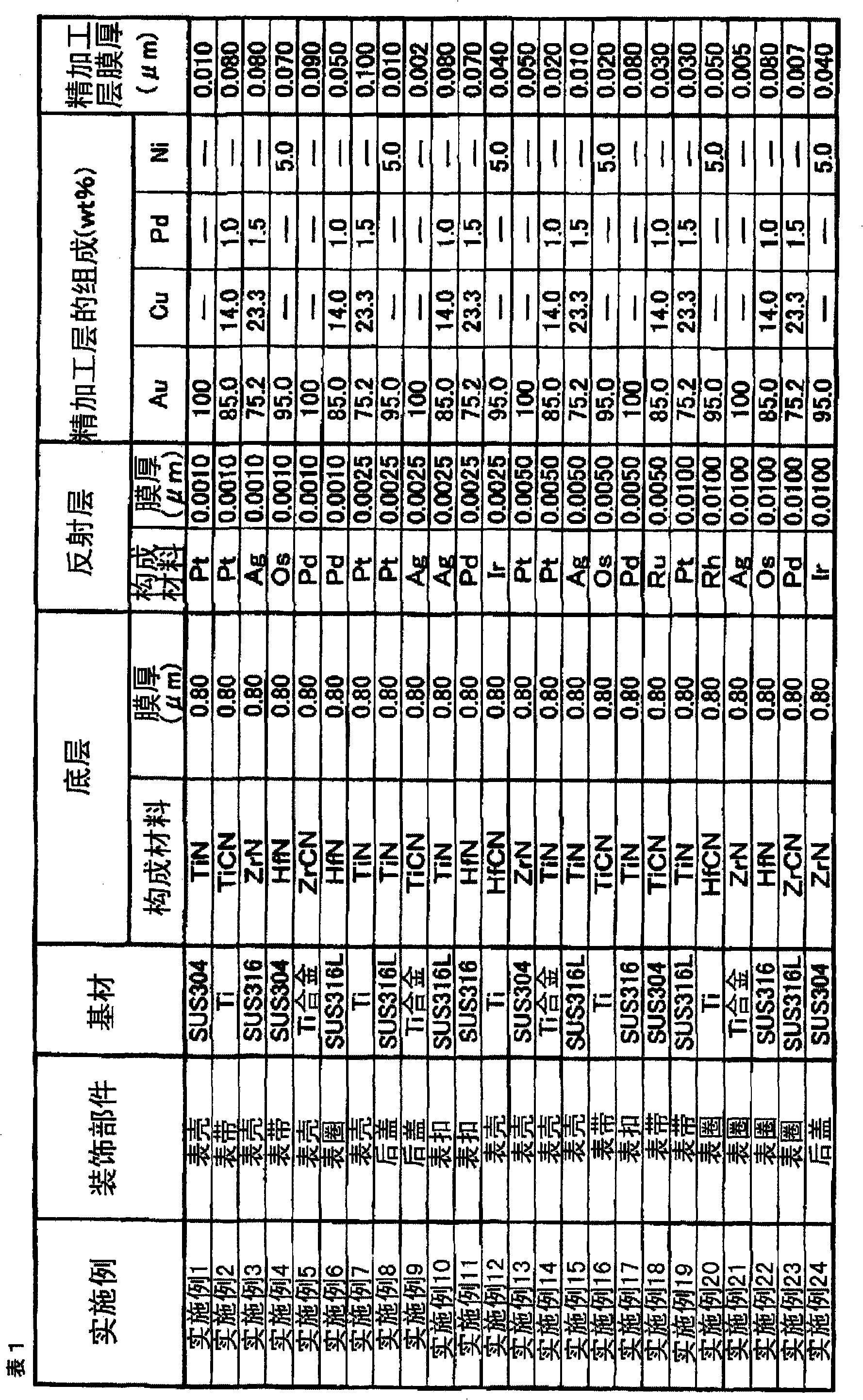

Embodiment 1

[0088] Arbitrary base material 14 is arranged in the vacuum device, Ar and nitrogen are introduced after carrying out vacuum evacuation in the vacuum device, and the mixed gas plasma of Ar and nitrogen is generated, and in the mixed gas plasma atmosphere whose pressure is maintained at 0.2Pa, A TiN layer is formed as the underlayer 13 on the surface of an arbitrary base material 14 by a DC sputtering method using Ti. Furthermore, using Pt in the same gas plasma atmosphere at the same pressure, the reflective layer 12 was formed on the underlayer 13 by a DC sputtering method. Further, in the same gas plasma atmosphere at the same pressure, an Au layer was formed on the reflective layer 12 by a DC sputtering method using Au, thereby forming the finishing layer 11 . The film thickness is a set value, and the film formation time is adjusted so that the TiN layer constituting the bottom layer 13 is 0.8 μm, the finishing layer 11 composed of Au is 0.01 μm (10 nm), and the total film...

Embodiment 2~24

[0090] Same as Example 1, introduce Ar and nitrogen after carrying out vacuum exhaust in the vacuum apparatus, produce the mixed gas plasma of Ar and nitrogen (or introduce Ar, nitrogen and CH 4 and generate a mixed gas plasma of Ar, nitrogen and carbon or hydrocarbons), in a mixed gas plasma atmosphere with a pressure of 0.2 Pa, use Hf, Ti or Zr to form HfN, HfCN, TiN, TiCN, The ZrN or ZrCN layer serves as an underlayer of any base material, thereby forming the underlayer 13 . Furthermore, in the same gas plasma atmosphere at the same pressure, the reflective layer 12 was formed on the under layer 13 by DC sputtering using Ru, Pd, Rh, Ag, Os, Ir, Pt. Further, in the same gas plasma atmosphere at the same pressure, Au or an Au alloy is used to coat the reflection layer 12 with Au or an Au alloy by a DC sputtering method to form the finishing layer 11 . The film thickness is a set value, and the HfN, TiN, TiCN or ZrN layer constituting the bottom layer 13 is adjusted to 0.8 μm...

Embodiment 25~47

[0092] Same as Example 1, introduce Ar and nitrogen after carrying out vacuum exhaust in the vacuum apparatus, produce the mixed gas plasma of Ar and nitrogen (or introduce Ar, nitrogen and CH 4 and generate a mixed gas plasma of Ar, nitrogen and carbon or hydrocarbons), in a mixed gas plasma atmosphere with a pressure of 0.2 Pa, use Hf, Ti or Zr to form HfN, HfCN, TiN, TiCN, The ZrN or ZrCN layer serves as an underlayer of any base material, thereby forming the underlayer 13 . Furthermore, in the same gas plasma atmosphere at the same pressure, the reflective layer 12 was formed on the under layer 13 by DC sputtering using Ru, Pd, Rh, Ag, Os, Ir, Pt. Further, in the same gas plasma atmosphere at the same pressure, Au or an Au alloy is used to coat the reflection layer 12 with Au or an Au alloy by a DC sputtering method to form the finishing layer 11 . Here, the thicknesses of the reflective layer and the finishing layer were adjusted to arbitrary thicknesses, and the film fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com