Horizontal flat pressing flat die-cutting creasing and thermoprinting machine

A technology of flattening and hot stamping machines, applied in the field of packaging machinery, which can solve the problems of increased cardboard shaking, many execution actions, and non-adjustability, and achieve the effect of increasing paper feeding speed and reducing waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

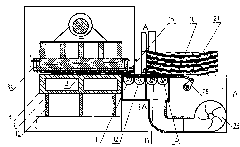

[0025] Such as Figure 1-2 As shown, a horizontal flat die-cutting creasing hot stamping machine is composed of an upper embossing pallet 30, a lower embossing pallet 31 and a paper feeding mechanism, and an eccentric shaft is arranged on the upper embossing pallet 30 device, under the imprinting lower pallet 31, there are lower pallet pressure adjustment upper slant iron 9 and lower pallet pressure adjustment lower slant iron 10, characterized in that: the embossing upper pallet 30 is a hollow shell body, the upper pallet pressure adjustment upper slant iron 7 and the upper pallet pressure adjustment lower slant iron 8 are longitudinally arranged in the cavity shell, and the pressure adjustment jackscrews are respectively arranged on the left and right side walls of the cavity shell, The pressure adjustment jackscrew on the left and right side walls adjusts the corresponding position of the left and right sides of the upper plate pressure adjustment upper inclined iron 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com