Automatic abrasive wheel cutting machine

A grinding wheel cutting machine, automatic technology, applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high price, waste of energy, etc., and achieve the effect of low pollution, energy saving, and automatic cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiments.

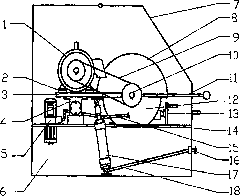

[0012] like figure 1 The specific embodiment given is an automatic grinding wheel cutting machine. The motor 1 is installed and fixed above the left end of the beam 3 through the backing plate 2, and the left end of the beam 3 is hinged and fixed to the workbench 14 through the hinge pair 4. The right end of the crossbeam 3 is equipped with a grinding wheel shaft assembly 10 and a grinding wheel 12, the grinding wheel shaft assembly 10 is equipped with an operating handle 11, the motor 1 drives the grinding wheel 12 to rotate through the transmission belt 9, and a grinding wheel protective cover 8 is installed on the grinding wheel 12 , the outermost is the cutting machine shell 7. Crossbeam 3 can rotate around hinge pair 4. A water tank 6 is installed below the workbench 14, and cooling liquid is housed in the water tank 6. Below the middle part of the crossbeam 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com