Independent horizontal disc

A flat-rotating disk, independent technology, applied in the field of flat-rotating disk, can solve the problems of unstable electric feed power transmission, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

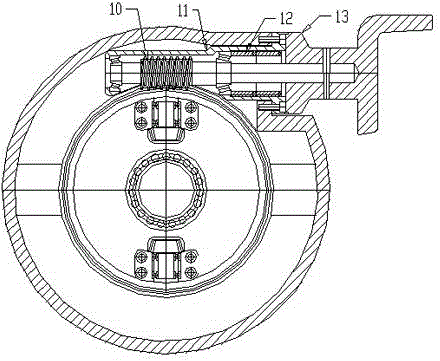

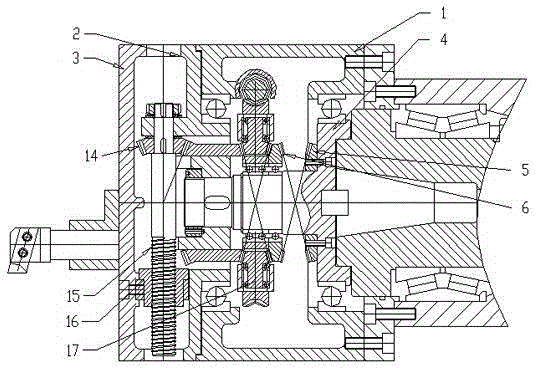

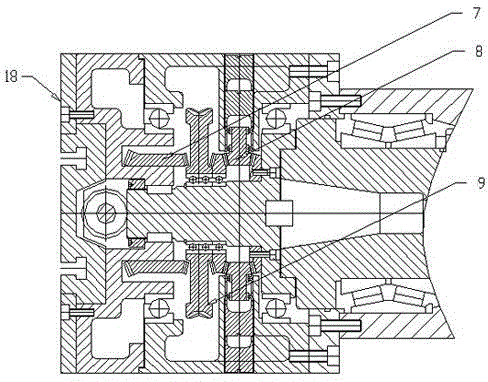

[0012] Such as figure 1 , figure 2 , image 3 As shown, the independent flat rotary disk of the present invention includes a cutter head, a cutter seat, a slider 3, and a pressing plate 18, and is mainly composed of a cylindrical fixed body 1, a rotating body 2, and a central axis 4. The fixed body 1 and The central shaft 4 and the rotating body 2 are flexibly connected by bearings, and the central shaft 4 passes through the center of the fixed body 1 and is tightly connected with the center hole of the rotating body 2; a pair of bevel gears 8 are arranged radially symmetrically inside the fixed body 1, and holes are opened on the housing The pot rod 10 is arranged vertically and axially, matched with the pot wheel 9, one end of the pot rod 10 is connected to the handle 13, the pot rod 10 is provided with a pot rod cover 11 and an adjusting screw 12; a bevel gear is arranged on the first step of the central axis 4 The ring 5 meshes with a pair of bevel gears 8 on the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com