Multi-claw type external diameter grinding device

A grinding device, claw-type technology, applied in grinding machines, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

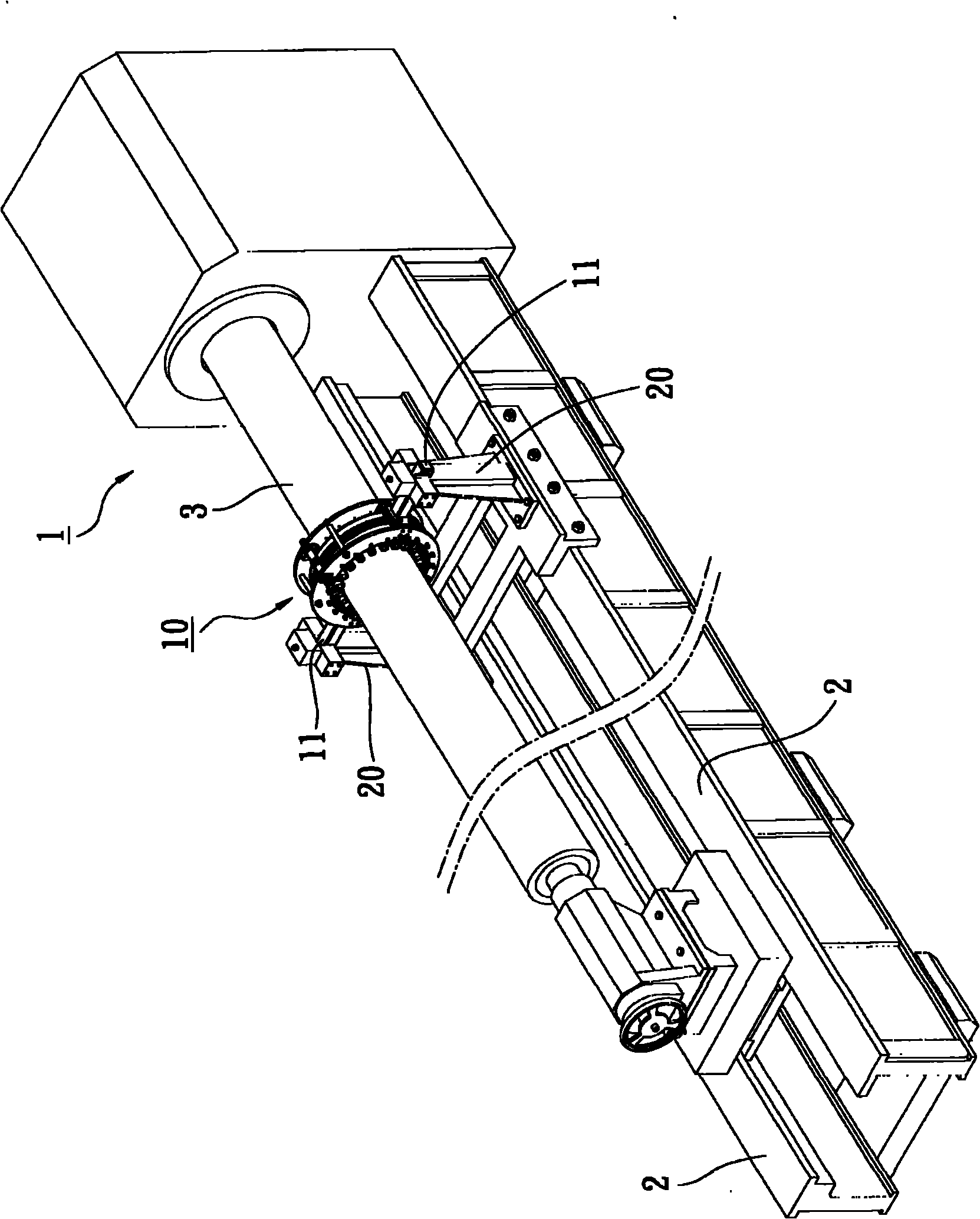

[0025] Please refer to figure 1 , figure 2 As shown, the present invention is a design of a multi-claw outer diameter grinding device, wherein a grinding head 10 and sliding seats 20 are arranged on both sides of the grinding head, so that the grinding head is hung on the sliding seats by cross bars 11 on both sides 20 and can slide on the slide rails 2 on both sides of the large grinding machine 1, and the two ends of the pipe fitting 3 to be ground are fixed between the rotating head and the tail cone seat, and can be driven to rotate.

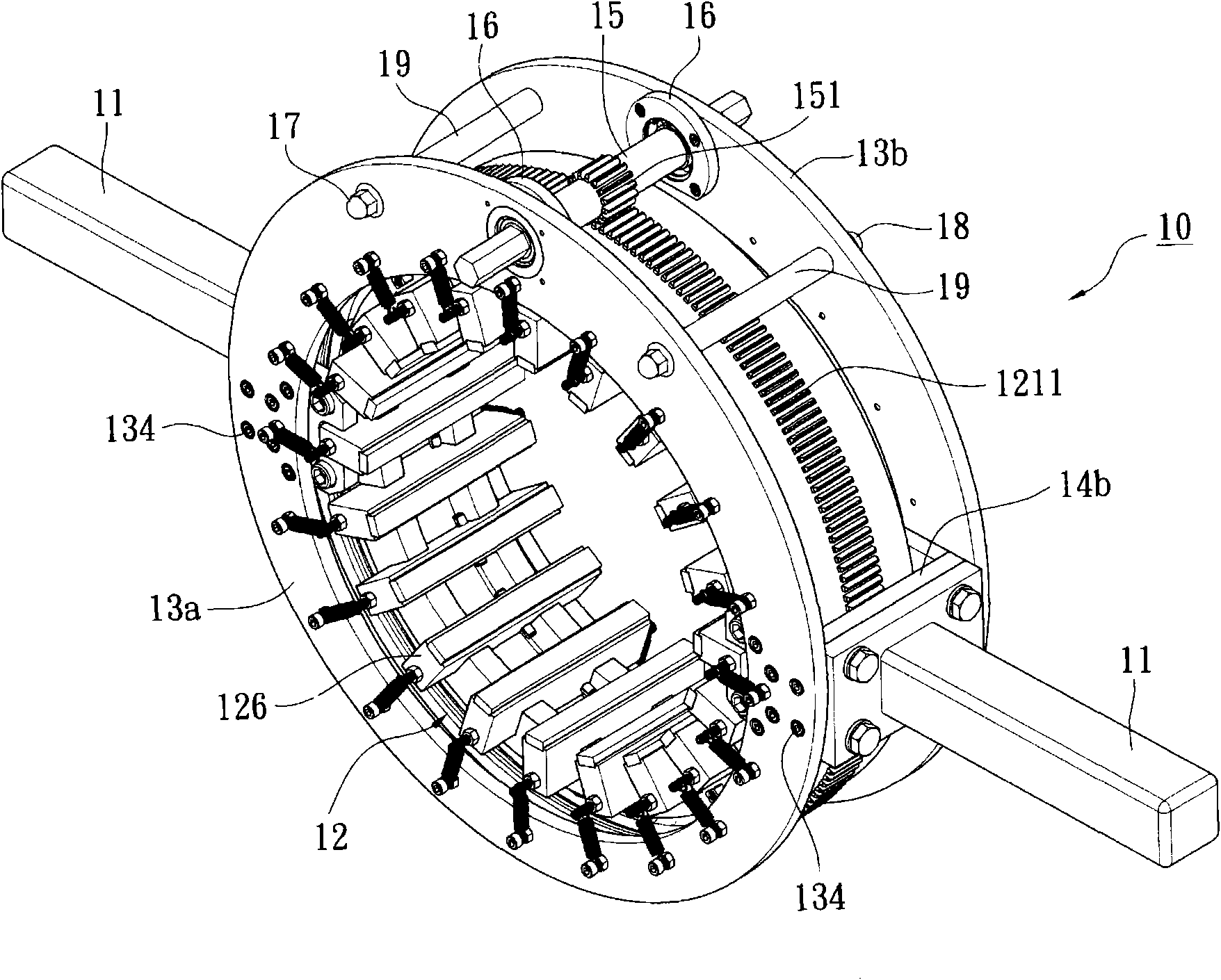

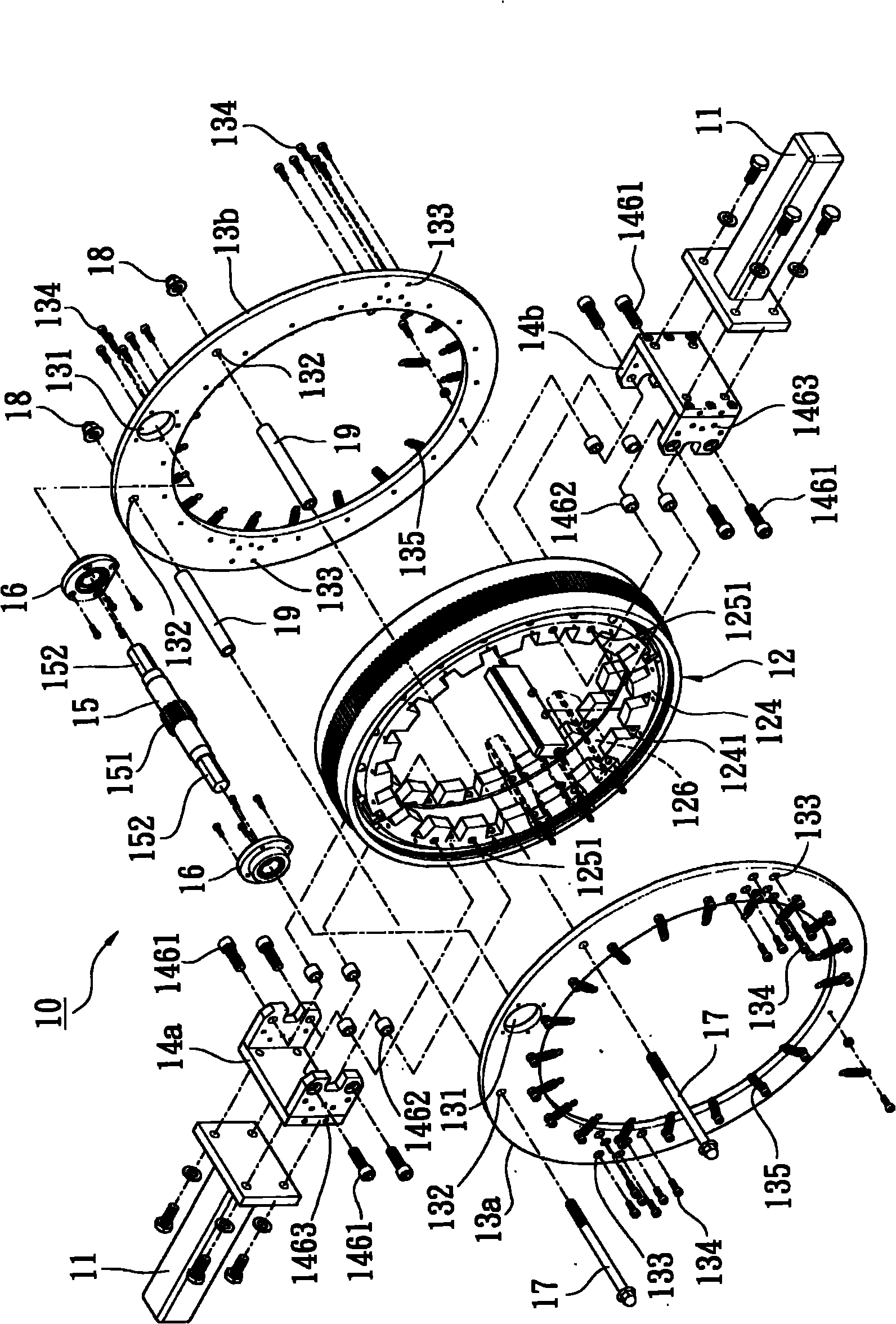

[0026] Please refer to figure 2 , image 3 As shown, the structure of the grinding head 10 is provided with a clamp seat 12, two outer baffles 13a, 13b, two locking seats 14a, 14b, a brake lever 15, two bearings 16, two long screw rods 17, two screw rods Cap 18 and tube 19 of fixed length.

[0027] Please refer to Figure 5 As shown, when assembling, at first the holder 12 needs to be combined, and the holder 12 is constructed with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com