Welding method of deck structure of stainless steel compound plate for railway steel bridge

A clad steel plate and welding method technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problem that stainless steel clad steel plate is not suitable for large-scale production of bridge deck structures, the labor intensity of welding workers is high, and the welding seam The quality is not easy to guarantee and other problems, to achieve the effect of facilitating mass production, ensuring corrosion resistance, and realizing mechanization and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

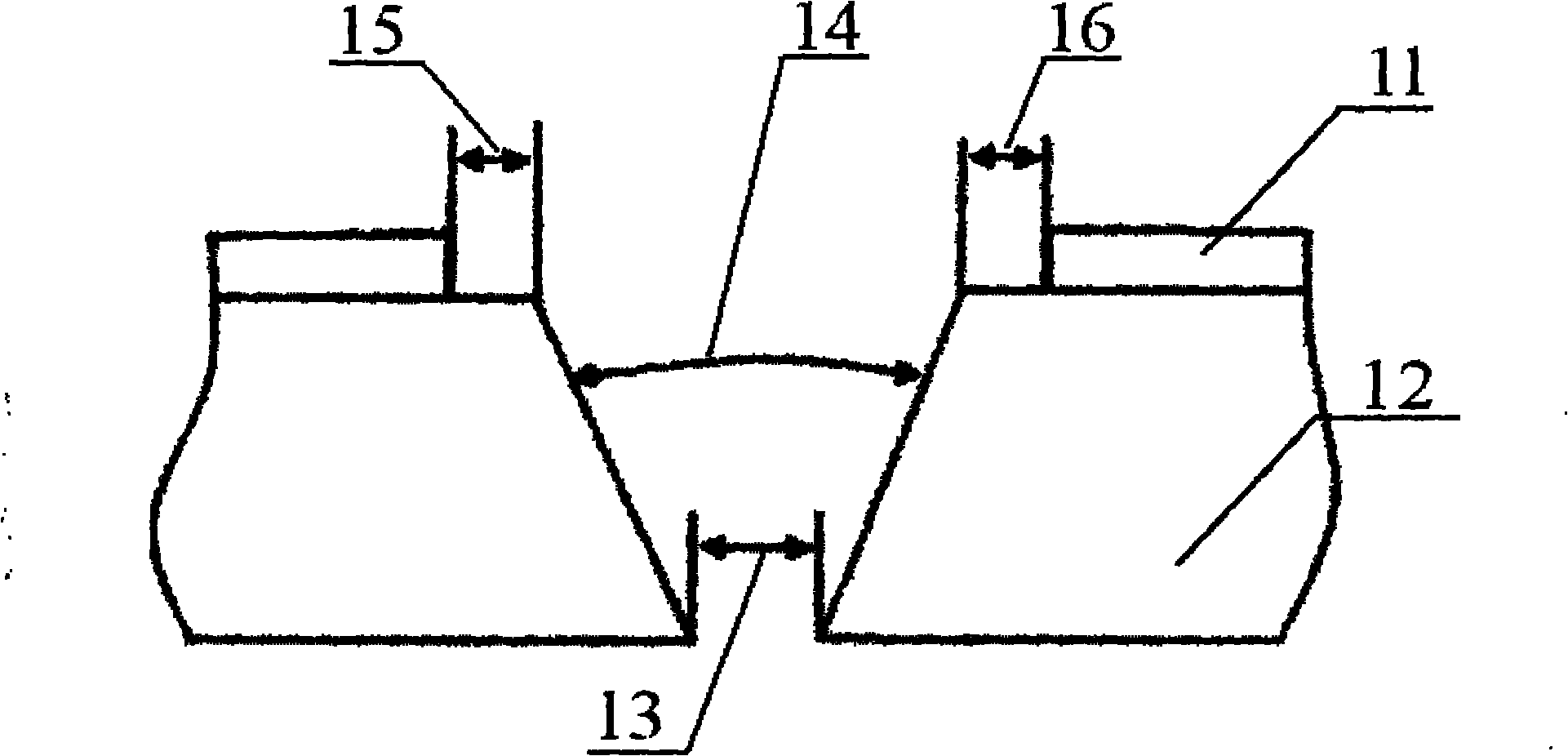

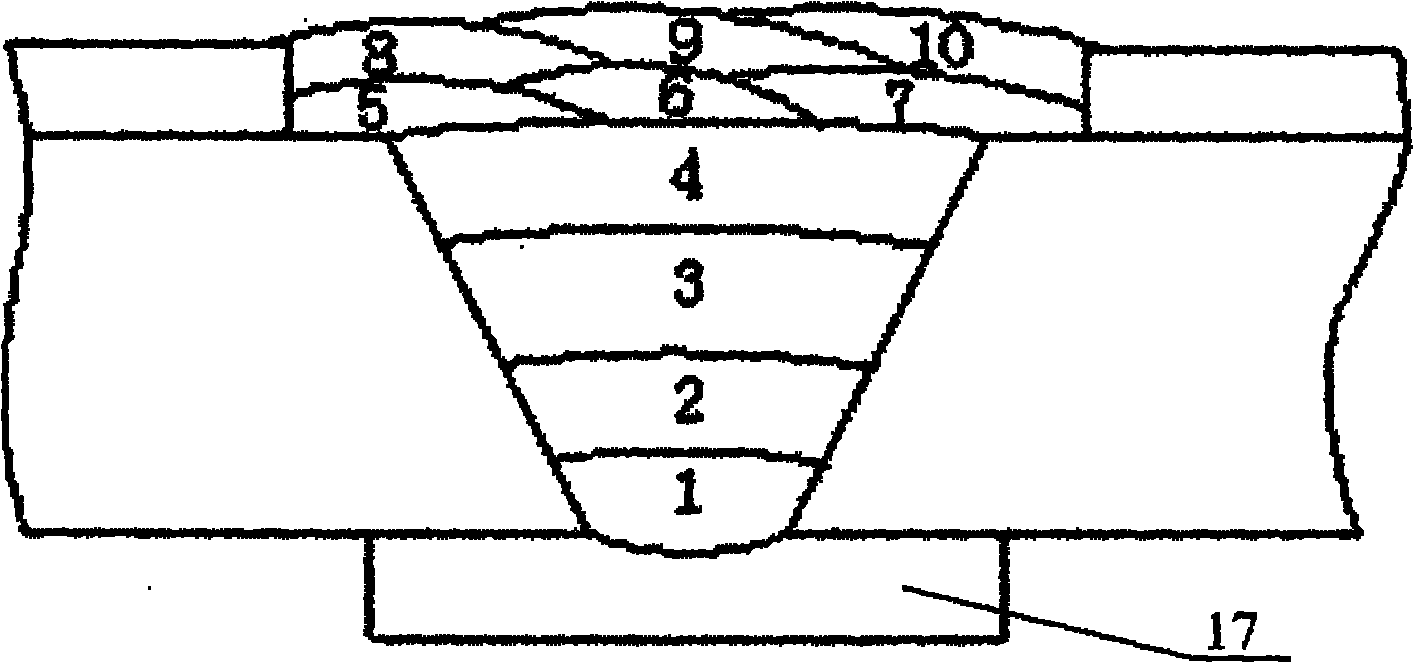

[0029] A method for welding the bridge deck structure of stainless steel clad steel plates for railway steel bridges. The material combination of the stainless steel clad steel plates is 321-Q370qE, wherein the thickness of the clad stainless steel 321 is 3 mm, and the thickness of the base layer Q370qE is 16 mm. Press 6 groups of 321-Q370qE stainless steel clad steel plates with dimensions (3+16)×200×600mm figure 1 The way to process the groove. The cladding material is pre-removed 3mm on both sides of the groove, the groove angle is 50°, and the groove spacing is 6mm.

[0030] The welding test conditions are as follows:

[0031] Welding equipment: YM-500KR2 Tangshan Panasonic CO 2 Gas shielded welding equipment, MUDE-1250 Shanghai Hengtong automatic submerged arc welding equipment.

[0032] Welding consumables for the base layer: YCJ501Ni-1 for backing welding, and H08Mn2E+SJ101q for each weld pass of the other base layers.

[0033] Welding material for transition layer:...

Embodiment 2

[0039] A method for welding the bridge deck structure of stainless steel clad steel plates for railway steel bridges. The material combination of the stainless steel clad steel plates is 347-Q370qE, wherein the thickness of the clad stainless steel 347 is 4mm, and the thickness of the base layer Q370qE is 20mm. Press 5 groups of 347-Q370qE stainless steel clad steel plates with dimensions (4+20)×200×600mm figure 1 The way to process the groove. The cladding material is pre-removed 6mm on both sides of the groove, the angle of the groove is 45°, and the distance between the grooves is 8mm.

[0040] The welding test conditions are as follows:

[0041] Welding equipment: YM-500KR2 Tangshan Panasonic CO 2 Gas shielded welding equipment, MUDE-1250 Shanghai Hengtong automatic submerged arc welding equipment.

[0042] Welding materials for the base layer: SQJ501Ni for backing welding, and H08Mn2E+SJ101q for each weld pass of the other base layers.

[0043] Welding material for tr...

Embodiment 3

[0049] A method for welding the bridge deck structure of stainless steel clad steel plates for railway steel bridges. The material combination of the stainless steel clad steel plates is 321-Q420qE, wherein the thickness of the clad stainless steel 321 is 3mm, and the thickness of the base layer Q420qE is 16mm. 8 groups of 321-Q420qE stainless steel clad steel plates with a size of (3+16)×200×600mm were pressed figure 1 The way to process the groove. The composite material is pre-removed 5mm on each side of the groove, the groove angle is 65°, and the groove distance is 4mm.

[0050] The welding test conditions are as follows:

[0051] Welding equipment: YM-500KR2 Tangshan Panasonic CO 2 Gas shielded welding equipment, MUDE-1250 Shanghai Hengtong automatic submerged arc welding equipment.

[0052] Welding consumables for the base layer: SQJ501Ni for backing welding, and CJQ-1+SJ101q for each weld pass of the other base layers.

[0053] Welding material for transition layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com