Sulfur condenser pipe head structure and welding method thereof

A condenser and tube head technology, which is applied in the field of sulfur condenser tube head structure and its welding, can solve the problems of difficult penetration and low pass rate of radiographic inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

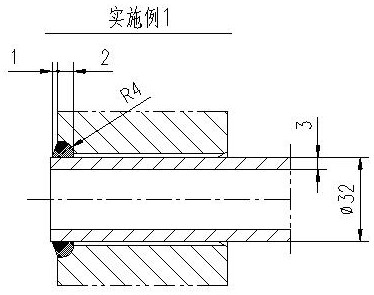

[0023] Example 1, such as image 3 As shown, a sulfur condenser tube head structure, the heat exchange tube specification is Φ32x3mm, the groove depth of the tube plate hole is 2mm, that is, the thickness of the groove weld is 2mm; The radius of the calculated arc is 2mm, and the minimum welding space at the root is considered as 4mm. The actual radius of the arc is 4mm; considering the wall thickness of the heat exchange tube is 3mm, the thickness of the uniform corrosion combined weld is not less than 3mm, and the overhang of the tube head is 1.5mm , fillet weld 1mm.

Embodiment 2

[0024] Example 2, such as Figure 4 As shown, a sulfur condenser tube head structure, the heat exchange tube specification is Φ45x5mm, the groove depth of the tube plate hole is 4mm, that is, the thickness of the groove weld is 4mm; the shape of the groove is arc-shaped, calculated by 1.5 times the depth The radius of the arc is 6mm, and the minimum welding space at the root is considered to be 4mm. The actual radius of the arc is 6mm; the wall thickness of the heat exchange tube is 5mm, and the combined weld thickness of the uniform corrosion is not less than 5mm, and the overhang of the tube head is 0.5mm , No fillet welds.

[0025] The welding method of the sulfur condenser pipe head structure described in above-mentioned embodiment 1 and embodiment 2, concrete steps are as follows:

[0026] (1) Control the groove depth deviation of tube sheet 2 to be (0, +0.3mm); it can effectively ensure the penetration of the root, and there will be no root infusion.

[0027] (2) Contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com