Welding with trailing extrusion device for friction stir welding and welding with trailing extrusion method thereof

A technology of friction stir welding and extrusion device, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of cumbersome clamping process, large clamping size, and narrow welding space, etc., to broaden the scope of application , Increase the welding space and the effect of high-quality connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

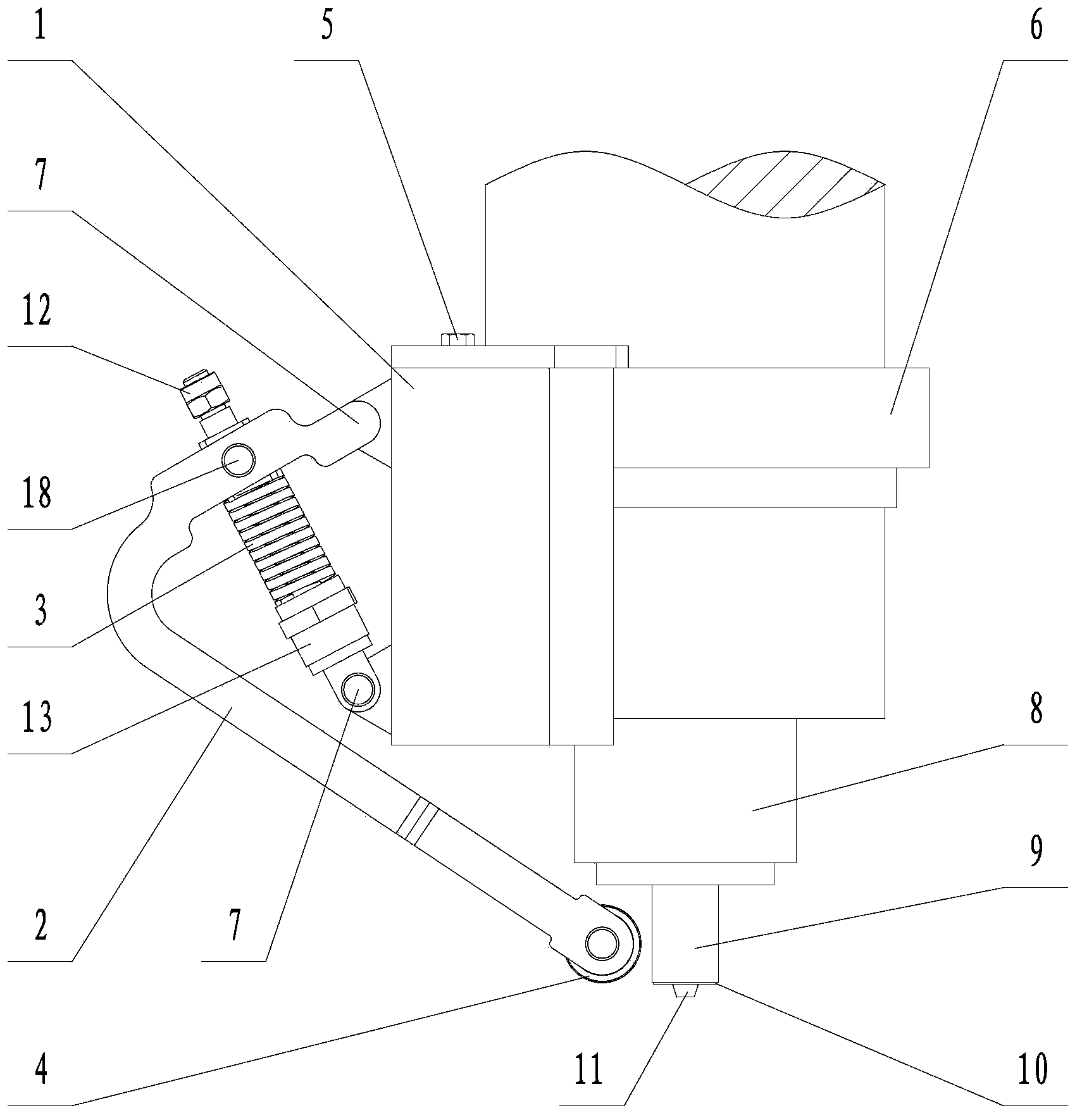

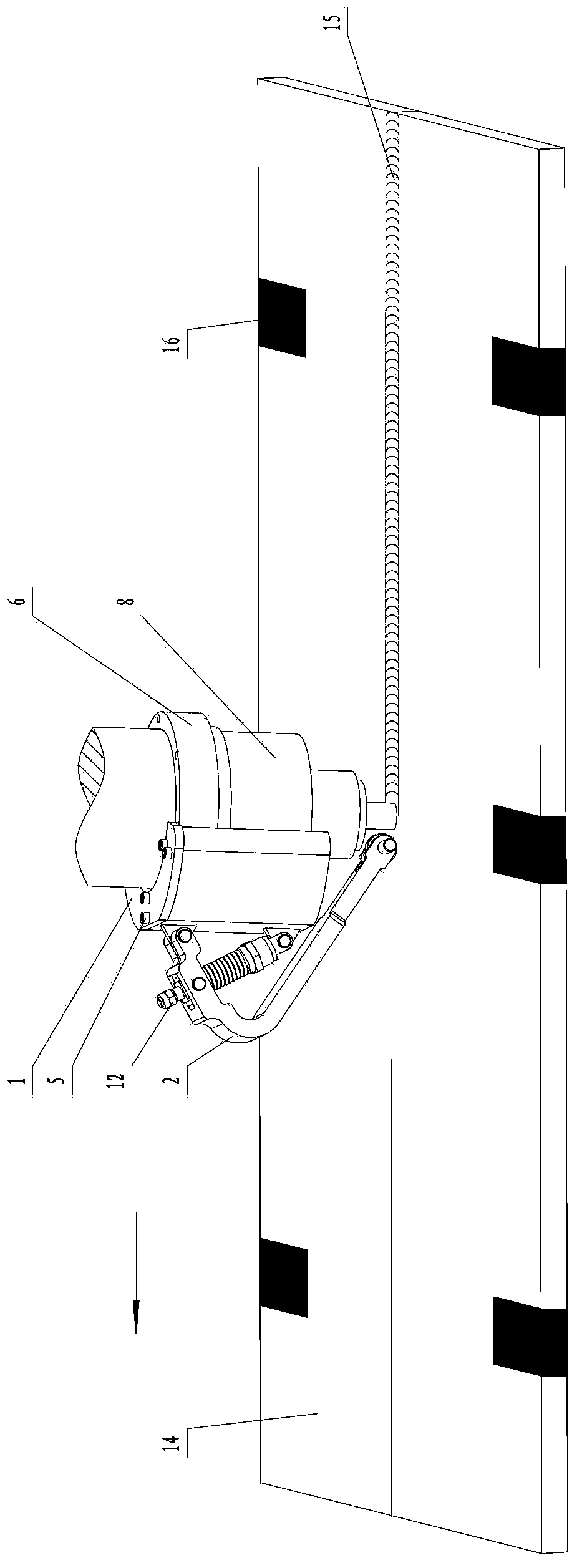

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 As shown, the extrusion device with welding of the present invention includes a support 1, a support arm 2, a force spring 3, an extrusion wheel 4, a nut 12 and a screw 13, and a static bushing 6 is installed on the main shaft 8 of the friction stir welding machine. The support 1 is fixed on the stationary shaft sleeve 6 through the first bolt 5 . The support arm 2 is "L"-shaped, with "U"-shaped grooves at both ends; one end of the support arm 2 is hinged on the support 1 through the first pin shaft 7, and the other end is equipped with a squeeze wheel 4. The wheel 4 is located in the "U" groove at the other end of the support arm 2 and is rotatable; the main shaft 8 is equipped with a welding tool 9 with a stirring pin 11, and the extrusion wheel 4 is located in front of the stirring pin 11 in the welding direction. On ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com