GIS device and three-phase common box bus bar cylinder

A technology of three-phase common box and busbar barrel, which is applied in the installation of busbar, setting of switchgear, switchgear, etc. It can solve the problems of difficult control of barrel quality, high scrap rate, insufficient production capacity, etc., and achieve easy quality control, The effect of simple structure and reduced length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

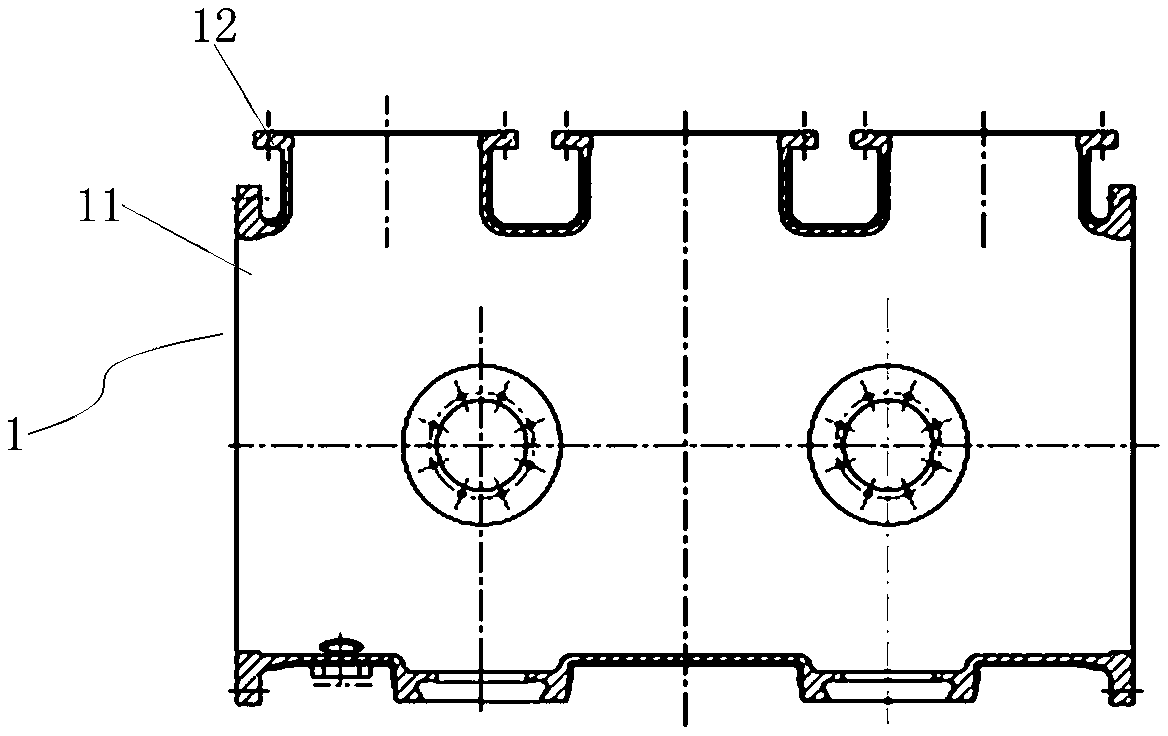

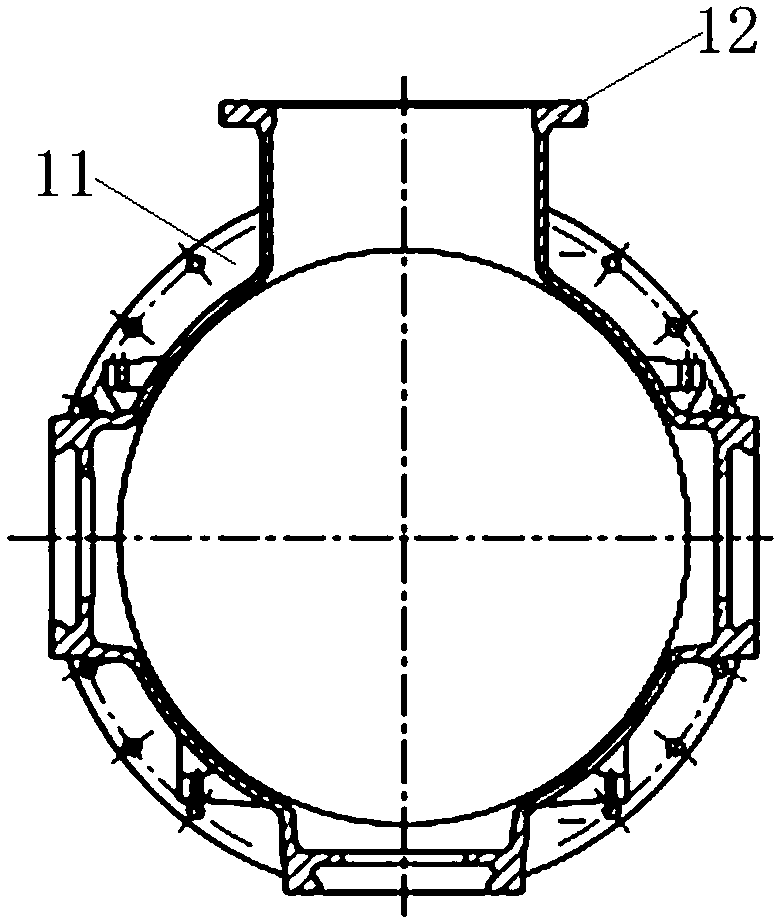

[0032] The specific embodiment of GIS equipment of the present invention, as Figure 3 to Figure 13 As shown, the GIS equipment includes a three-phase common box busbar barrel 1, and the three-phase shared box busbar barrel includes a barrel body 11, and three single-phase Attachment mounting holes 6, single-phase attachment mounting flanges 13 are fixedly installed on the edges of the three single-phase attachment mounting holes 6, and pot insulators 2 are installed on the single-phase attachment mounting flanges 13, which are also used for installation isolation Structures such as switches or circuit breakers. In the present invention, the single-phase accessory mounting flange 13 is a neckless plate flange. Compared with the necked flange in the prior art, the height of the plate flange is lower, which can reduce the size of the single-phase accessor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com