Conductive paste and light permeability conductive film and method of manufacturing the same

A conductive and paste technology, applied in the field of conductive paste and light-transmitting conductive film and its manufacturing, can solve the problems of reduced printing suitability, difficult contact, high thixotropy of conductive paste, and low cost , The effect of inhibiting drying and thin line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~2

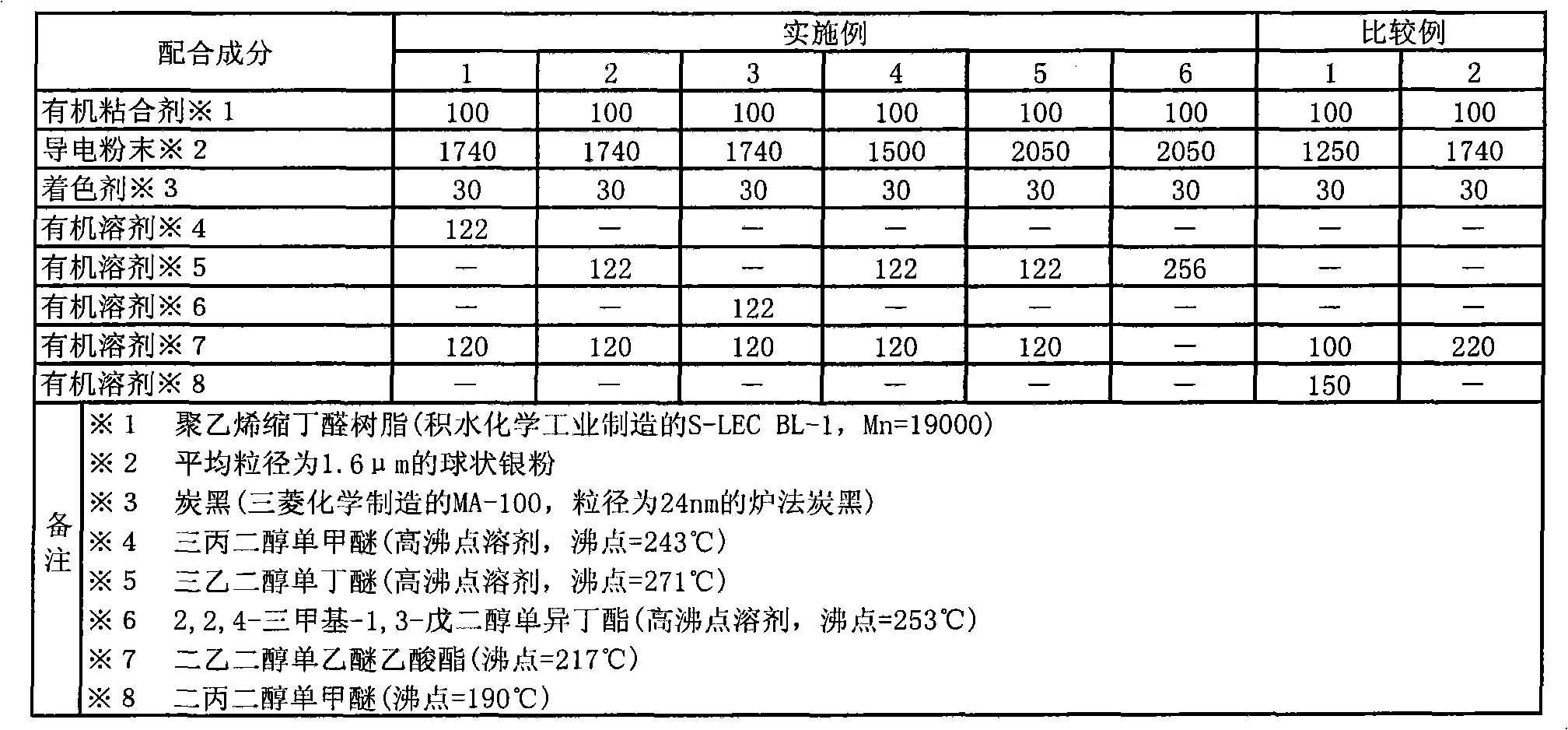

[0064]Each component was mixed according to the compounding ratio shown in Table 1, and it kneaded with the 3-roll kneader, and obtained the conductive paste. In addition, after kneading, the viscosity was adjusted to 500 dPa·s with an organic solvent, and then evaluated.

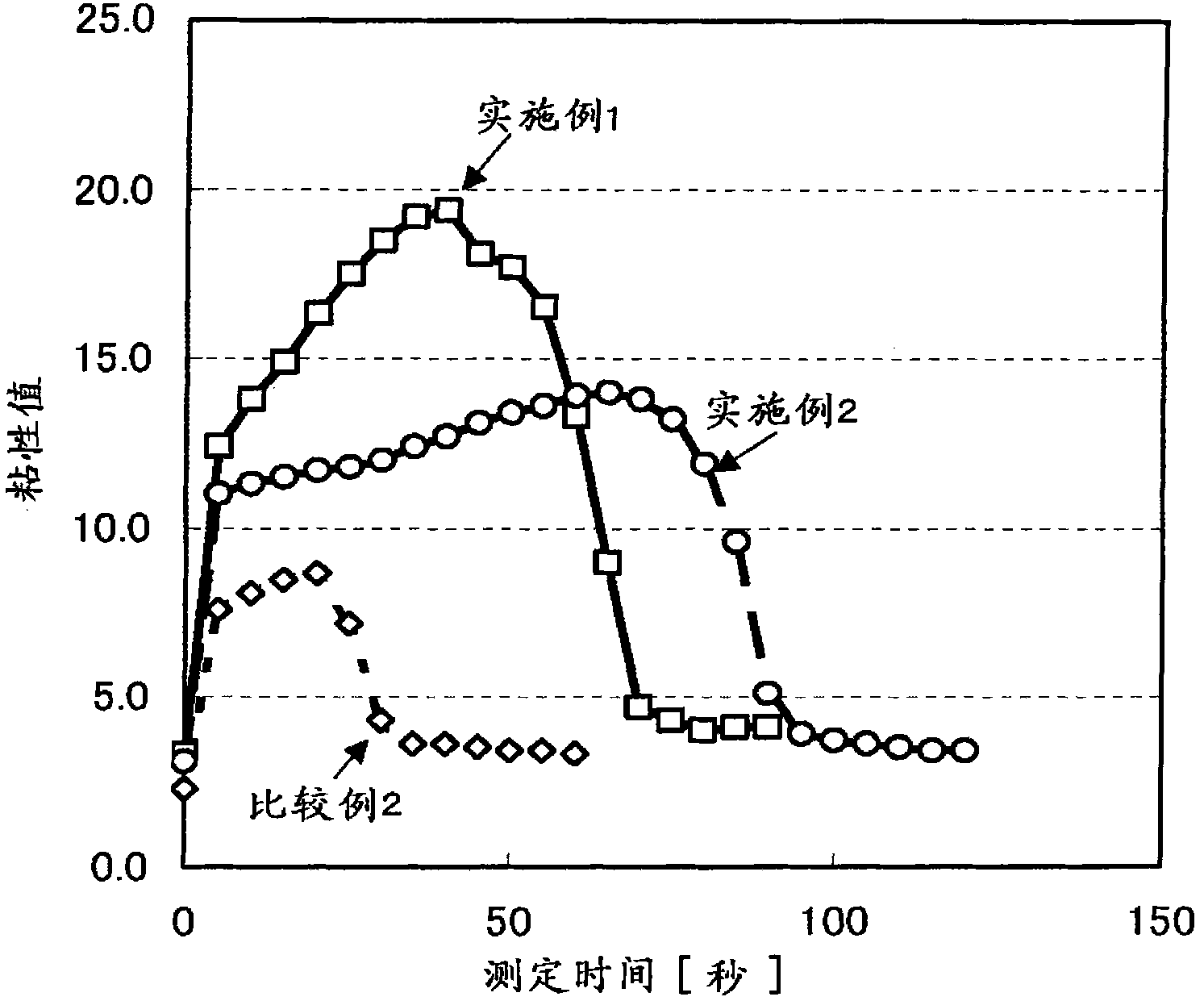

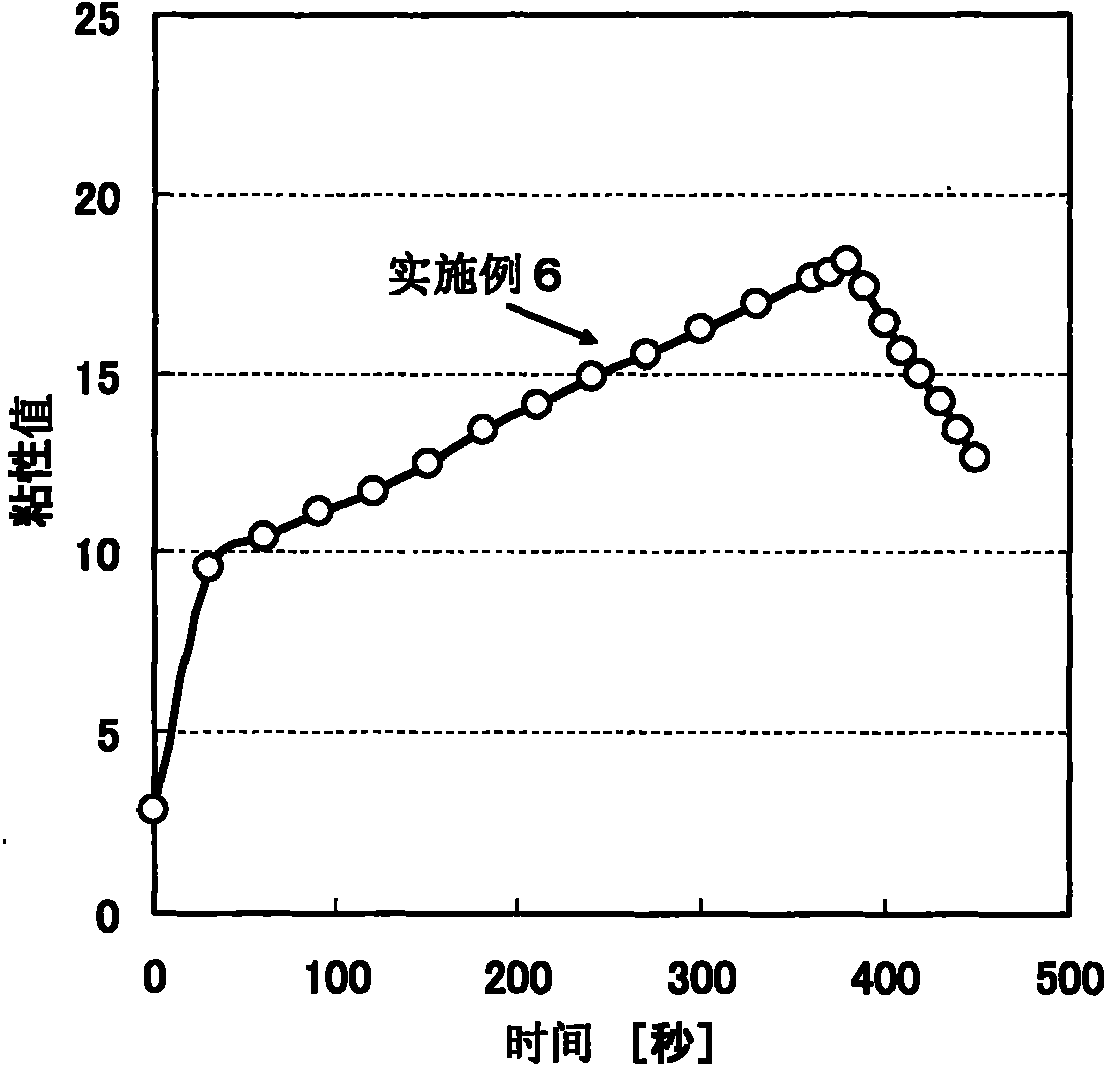

[0065] [Table 1]

[0066]

[0067] The conductivity, printability, drying resistance, and tack value of the various conductive pastes thus obtained were evaluated. The evaluation method is as follows.

[0068] (1) Evaluation of electrical conductivity

[0069] The obtained various conductive paste patterns were printed on a glass substrate to form a 0.5 cm×10 cm pattern, and heat treatment was performed at 120° C. for 30 minutes to form a 0.5 cm×10 cm conductive pattern. The sheet resistance value of the conductive pattern was measured by a four-probe method using a milliohm high tester, and the resistivity value was calculated from the measured value of the thin layer and the film thickness to eval...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com