Split gas sample injection device

A gas sampling and sampling technology, applied in the direction of material electrochemical variables, etc., can solve the problems that cannot meet the fast and accurate analysis requirements of the central control, the injection volume cannot be adjusted at any time, waste manpower and material resources, etc., to achieve simplified operation, The effect of saving time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

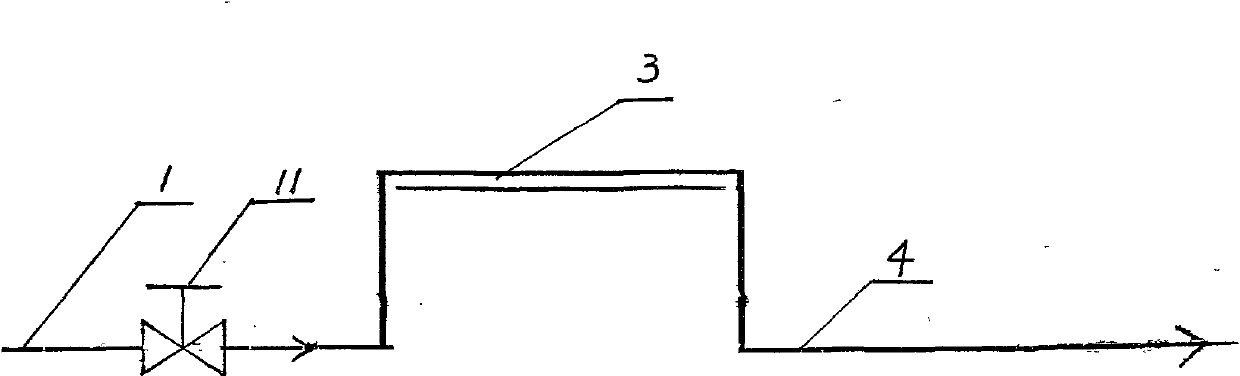

[0035] according to figure 1 As shown, the current traditional sampler is that the sample carrier gas pipe 1 is connected to the inlet of the needle valve 11, the outlet of the needle valve 11 is connected to the six-way valve and the quantitative tube 3, and the gas sent out by the six-way valve and the quantitative tube 3 The carrier gas and sample enter the coulometer through the delivery pipe 4.

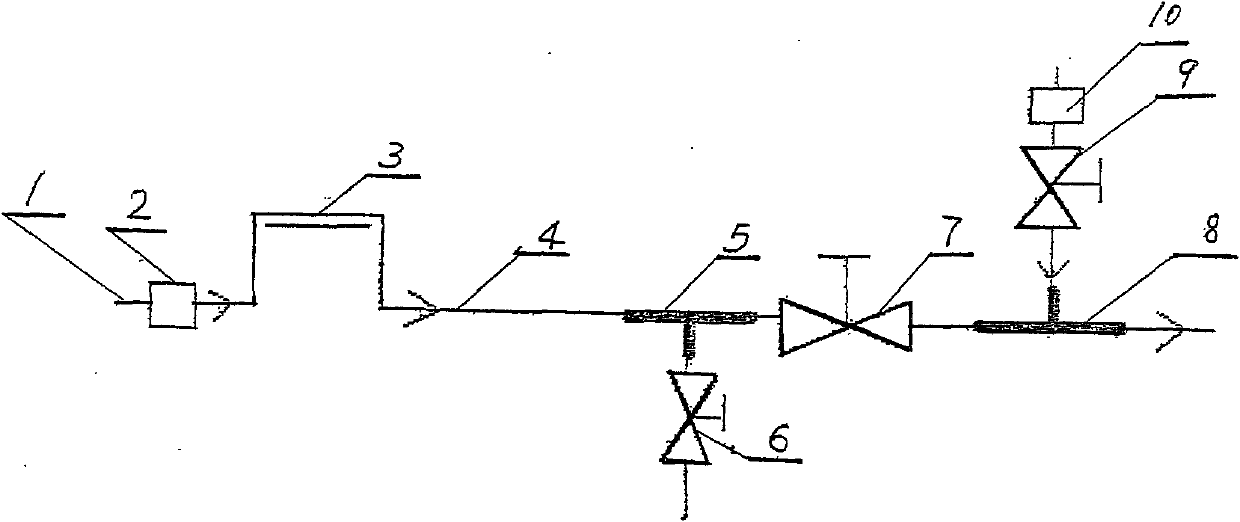

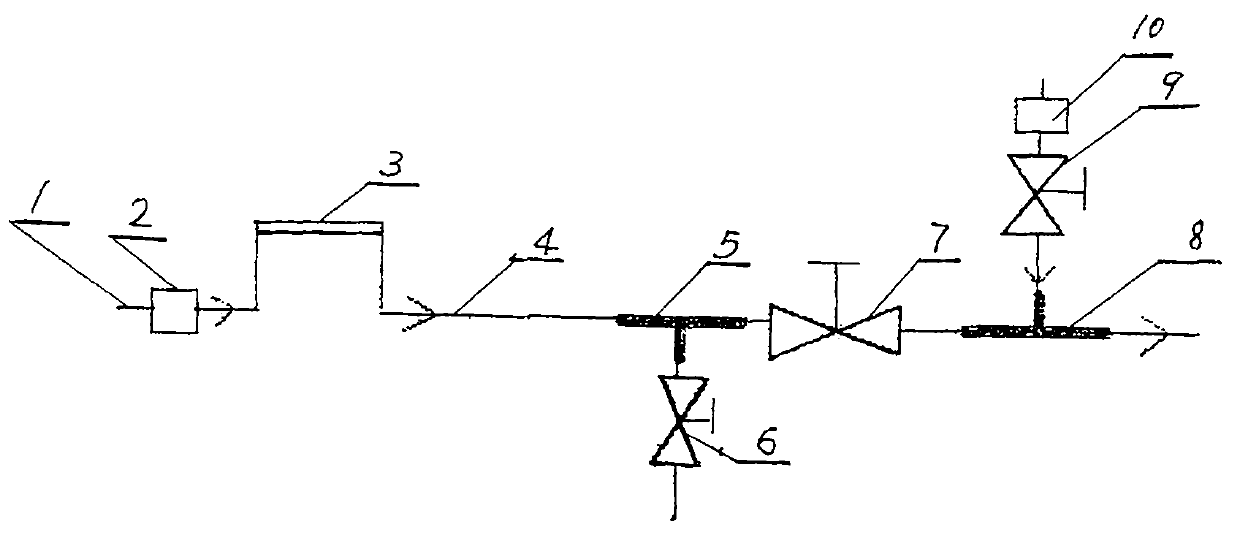

[0036] according to figure 2 As shown, the present invention is provided with a pressure stabilizing valve 2 on the sample injection carrier gas pipe 1, the sample injection carrier gas pipe 1 communicates with the six-way valve and the quantitative tube 3, and the outlet of the six-way valve and the quantitative tube 3 is connected to the sample injection carrier gas and sample delivery The pipe 4 is connected, and a three-way shunt pipe 5 is set on the sample carrier gas and sample delivery pipe 4. The shunt outlet of the three-way shunt pipe 5 is provided with a needle valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com