Structure of connection of circular steel tube type lightweight aggregate concrete beam and through reinforcing steel bar of concrete pier and construction process thereof

A technology of lightweight aggregate concrete and reinforced concrete, which is applied in bridges, bridge parts, bridge construction, etc., to achieve the effects of reducing the structure's self-weight, reliable connection, and reducing foundation loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

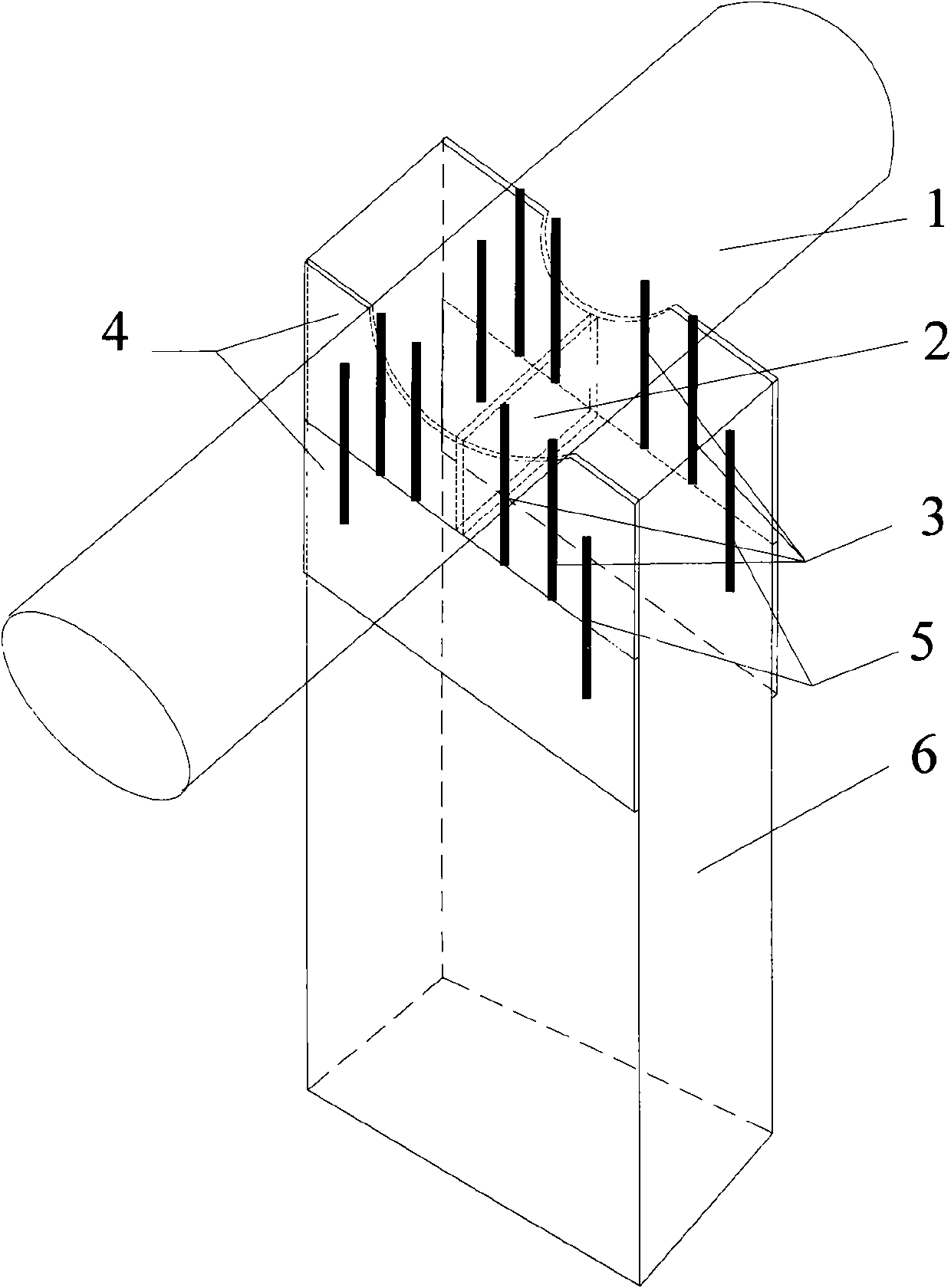

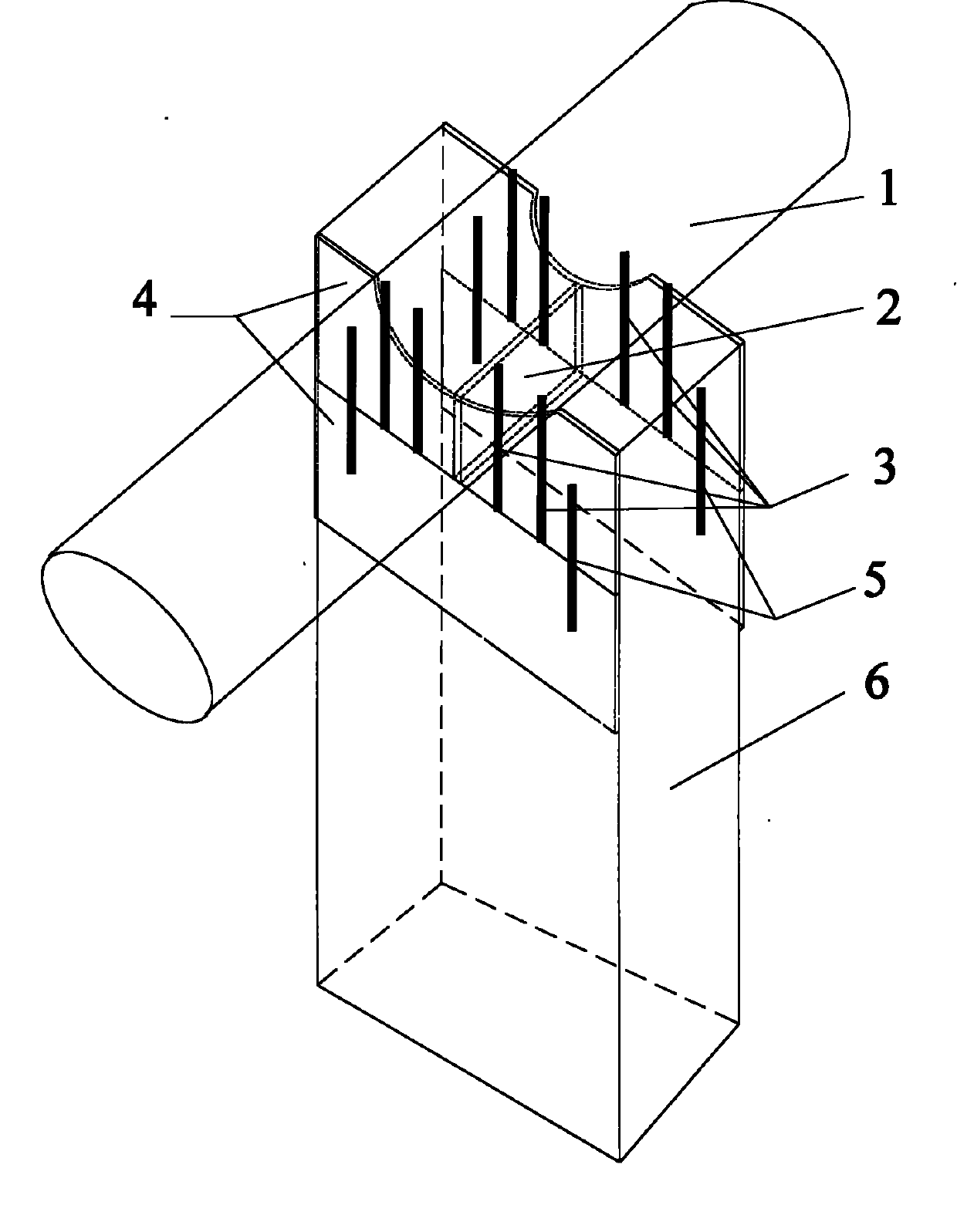

[0019] figure 1 It is a welded piercing reinforcement connection between circular steel pipe light aggregate concrete beams and reinforced concrete piers. Firstly, the required components are manufactured in the factory. , then pour light aggregate concrete into the steel pipe; weld the shear force transfer steel plate 2 and the bending moment transfer steel plate 4, and then weld the protruding part of the piercing steel bar 3 to the bending moment transfer steel plate 4; Moment transmission steel plate 4, and weld two steel bars 5 on the welded steel plate to strengthen the connection performance of the moment transmission plate, and then weld two rows of perforated steel ribs (the diameter of the hole is larger than the diameter of the longitudinal reinforcement of the reinforced concrete pier 6) ; When tying the steel bars, pass the longitudinal steel bars of the pier through the steel rib plate holes first, then tie the steel bars, set up the formwork, and pour concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com