Heat pipe, manufacture method and special equipment

A technology of heat pipes and tubes, which is applied in the field of heat conduction, can solve the problems of shortened service life, reduced effect, intermittent heat conduction, etc., and achieve the effects of resisting impact erosion, avoiding corrosion, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step, the preparation of the bottom glaze layer

[0031] Take out the steel pipe that diameter is 10 millimeters, wall thickness is 1.5 millimeters, and its surface is carried out derusting treatment;

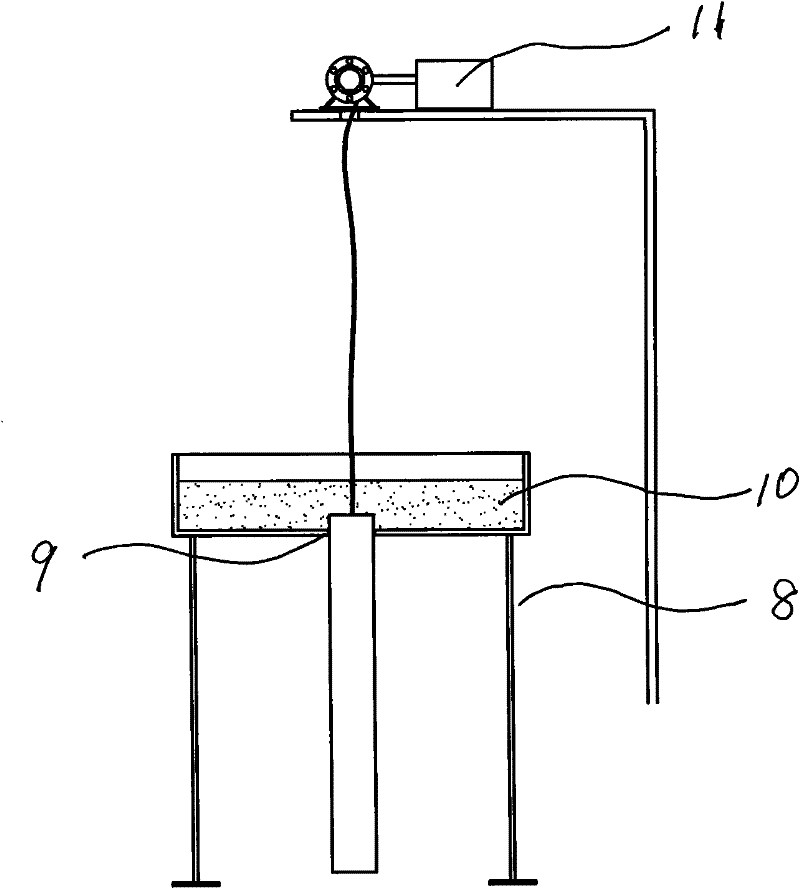

[0032] Then prepare the bottom glaze layer material, that is, take 4.5 kg of silicon dioxide, 0.3 kg of dipotassium oxide, 0.9 kg of boron trioxide, 0.6 kg of sodium fluorosilicate, 0.5 kg of aluminum oxide, 0.7 kg of Disodium oxide and 0.6 kg of calcium fluoride, add water to make its concentration 70%, put the resulting solution into image 3 In the shown container 10, then at an ambient temperature of 25°C, start the traction mechanism 11 set on the fixed frame, so that the steel pipe passes through the hole in the center of the container, and the bottom glaze layer in the container, that is, the bottom glaze layer Coat and hang on the outer wall of the tube; adjust the traction speed of the tube so that the thickness of the bottom glaze layer coated on the...

Embodiment 2

[0037] The first step, the preparation of the bottom glaze layer

[0038] Take out the steel pipe that diameter is 20 millimeters, wall thickness is 2.0 millimeters, and its surface is carried out derusting treatment;

[0039] Then prepare the bottom glaze layer material, namely take 4.0 kg of silicon dioxide, 0.4 kg of dipotassium oxide, 1.2 kg of boron trioxide, 0.7 kg of sodium fluorosilicate, 0.4 kg of aluminum oxide, 0.8 kg of Disodium oxide and 0.6 kg of calcium fluoride, add water to make its concentration 65%, put the resulting solution into image 3 In the shown container 10, then at an ambient temperature of 28°C, start the traction mechanism 11 arranged on the fixed frame, so that the steel pipe passes through the hole in the center of the container and the bottom glaze layer material in the container, that is, the bottom glaze layer material is coated Hang on the outer wall of the tube; adjust the traction speed of the tube so that the thickness of the bottom glaz...

Embodiment 3

[0044] The first step, the preparation of the bottom glaze layer

[0045] Take out the steel pipe that diameter is 25 millimeters, wall thickness is 3.0 millimeters, and its surface is carried out derusting treatment;

[0046] Then prepare the bottom glaze layer material, namely take 4.2 kg of silicon dioxide, 0.5 kg of dipotassium oxide, 1.0 kg of boron trioxide, 0.7 kg of sodium fluorosilicate, 0.5 kg of aluminum oxide, 0.9 kg of Disodium oxide and 0.6 kg of calcium fluoride, add water to make its concentration 72%, put the prepared solution into image 3 In the shown container 10, then at an ambient temperature of 30°C, start the traction mechanism 11 arranged on the fixed frame, so that the steel pipe passes through the hole in the center of the container and the bottom glaze layer material in the container, that is, the bottom glaze layer material is coated Hang on the outer wall of the tube; adjust the traction speed of the tube so that the thickness of the bottom glaze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com