Comprehensive mechanized coal mining method through cantilever support

A comprehensive mechanization and suspension support technology, applied in cutting machinery, mine roof support, ground mining, etc., can solve the problems of high labor intensity of coal miners, insecure safety conditions, and low yield per unit area of the working face, achieving the essence of realization Sexual safety, labor intensity liberation, changing the effect of repeated transportation and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

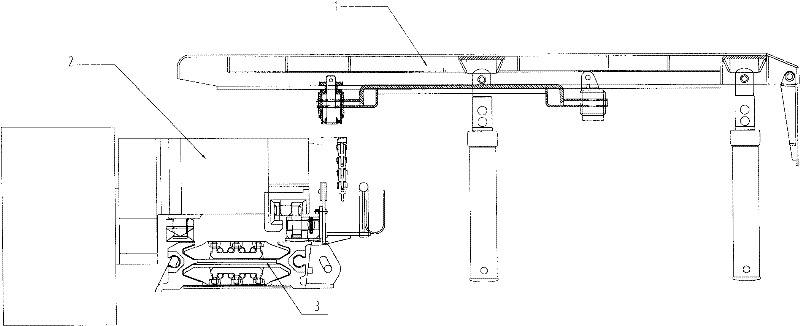

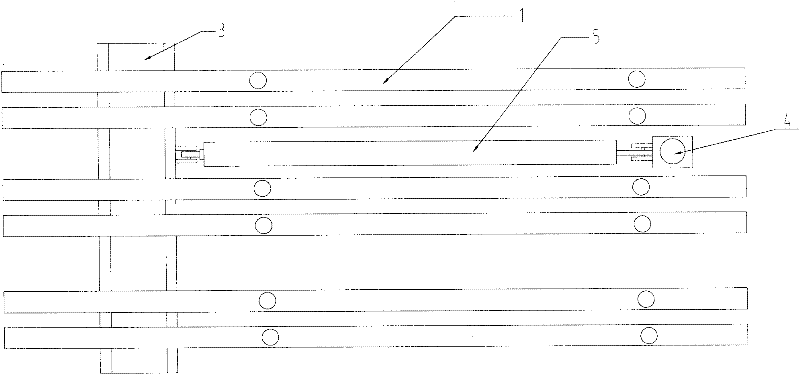

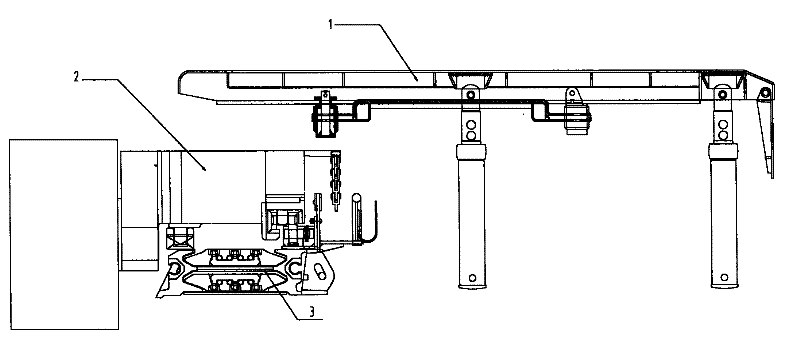

[0024] The comprehensive mechanized coal mining method with suspended support in this embodiment includes the following steps: laying the scraper conveyor 3 along the working face; installing the coal shearer 2 on the scraper conveyor 3 and debugging and running it; Suspension support 1; set and install the hydraulic top cutting pier column 4 on the working surface; one end of the push jack 5 is hinged with the hydraulic top cutting pier column 4, and the other end is hinged with the scraper conveyor 3; start the mining The coal machine 2 cuts the coal wall, and the cut coal automatically falls onto the scraper conveyor 3; the scraper conveyor 3 is started to automatically transport the coal out; when the shearer cuts a certain depth, The telescopic rod of the pushing jack 5 is stretched out, and the hydraulic cutting pier 4 is used as a fixed fulcrum to push the scraper conveyor 3 and the shearer 2 arranged on it toward the coal wall together; The hydraulic cutting pier colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com