Efficient biological treatment method for polymer-containing sewage in oil field

A biological treatment and sewage technology, applied in sustainable biological treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., can solve problems such as failure to meet environmental protection requirements, unstable process operation, poor biodegradability, etc., to achieve Small investment, easy handling, and the effect of alleviating corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

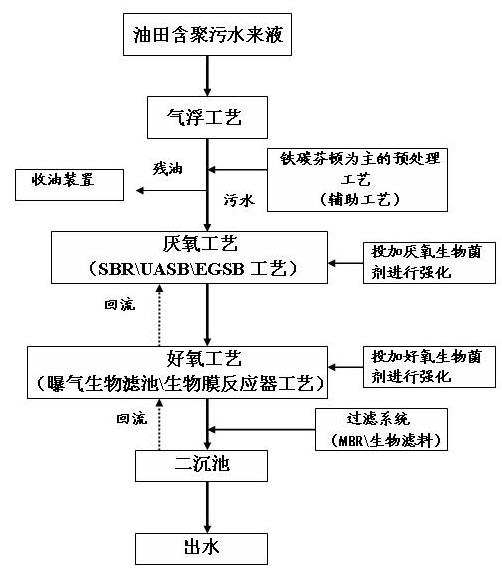

[0013] Specific embodiment one: the efficient biological treatment method of oil field poly-containing sewage in this embodiment is realized according to the following steps: 1. After the oil field poly-contained sewage is treated by air flotation process, the sewage produced adopts anaerobic process to carry out bio-augmentation, and the hydraulic retention time is 24 to 36 hours; 2. The effluent produced by the anaerobic process is strengthened by the aerobic process, and the hydraulic retention time is 10 to 14 hours, and then the effluent enters the filtration system, and the hydraulic retention time is 5 to 8 hours; 3. Filtration The effluent produced by the system enters the secondary sedimentation tank, and the hydraulic retention time is 5 to 6 hours, which means that the efficient biological treatment of the oilfield wastewater containing polymers is completed.

[0014] In step 1 of this embodiment, the oilfield wastewater containing polyacrylamide refers to the oilfie...

specific Embodiment approach 2

[0018] Specific embodiment two: this embodiment differs from specific embodiment one in that the anaerobic process in step one is UASB (upflow anaerobic sludge bed), SBR (sequenced batch activated sludge process) or EGSB (expanded granular sludge mud bed). Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the anaerobic process needs to add anaerobic biological bacteria agent in step one, and the anaerobic biological bacteria agent is anaerobic polyacrylamide degradation functional flora and anaerobic petroleum Degrading bacteria, the dosage accounts for 1% to 5% of the volume of effective sewage in the reaction tank. Other steps and parameters are the same as those in Embodiment 1.

[0020] In this embodiment, the anaerobic polyacrylamide degrading functional flora degrades high-molecular-weight water-soluble polyacrylamide into low-molecular-weight compounds, and then converts them into carbon and nitrogen sources needed for microbial metabolism to achieve microbial biodegradation; Oxypolyacrylamide-degrading functional bacteria were screened from polymer injection process wastewater and polymer-containing wastewater by conventional methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com