Novel active copper-phosphorus brazing alloy

A copper-phosphorus solder and active technology, applied in the direction of welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problems of narrow application, failure to meet customers, difficult processing, etc., to prevent overheating or overburning , Excellent process performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

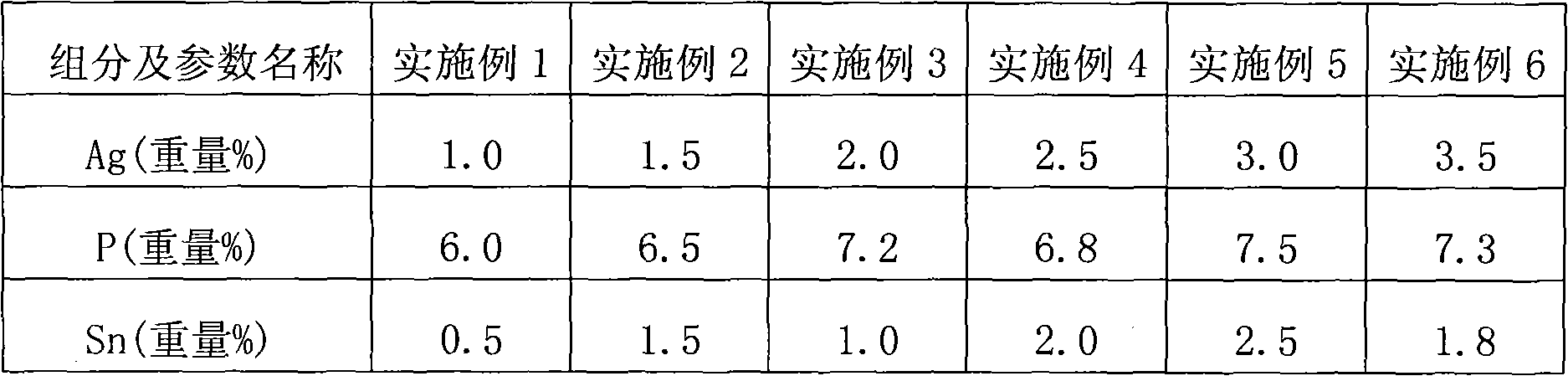

[0018] Table 1 embodiment 1-embodiment 6 related data table

[0019]

[0020]

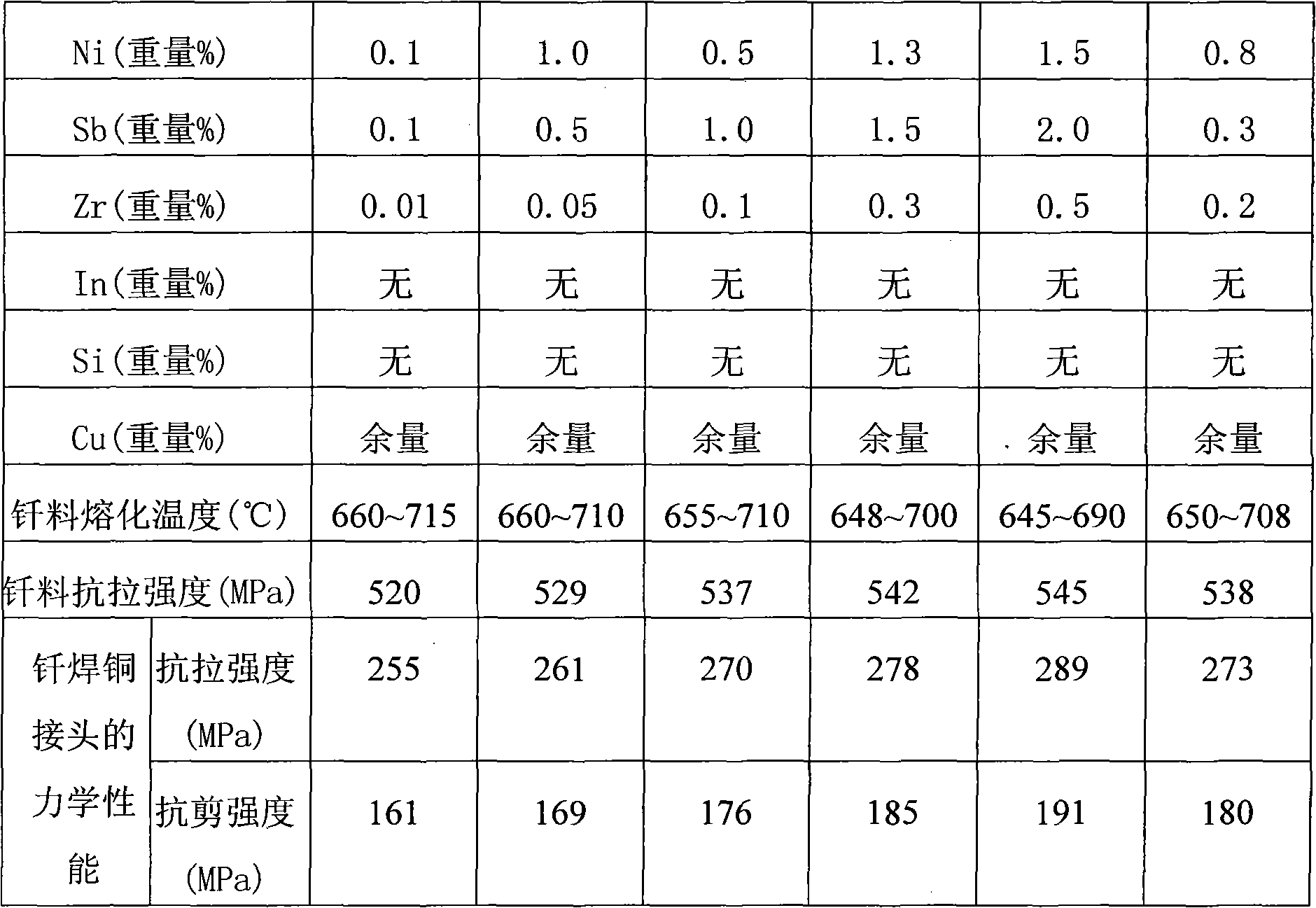

[0021] Table 2 embodiment 7-embodiment 12 related data table

[0022]

[0023]

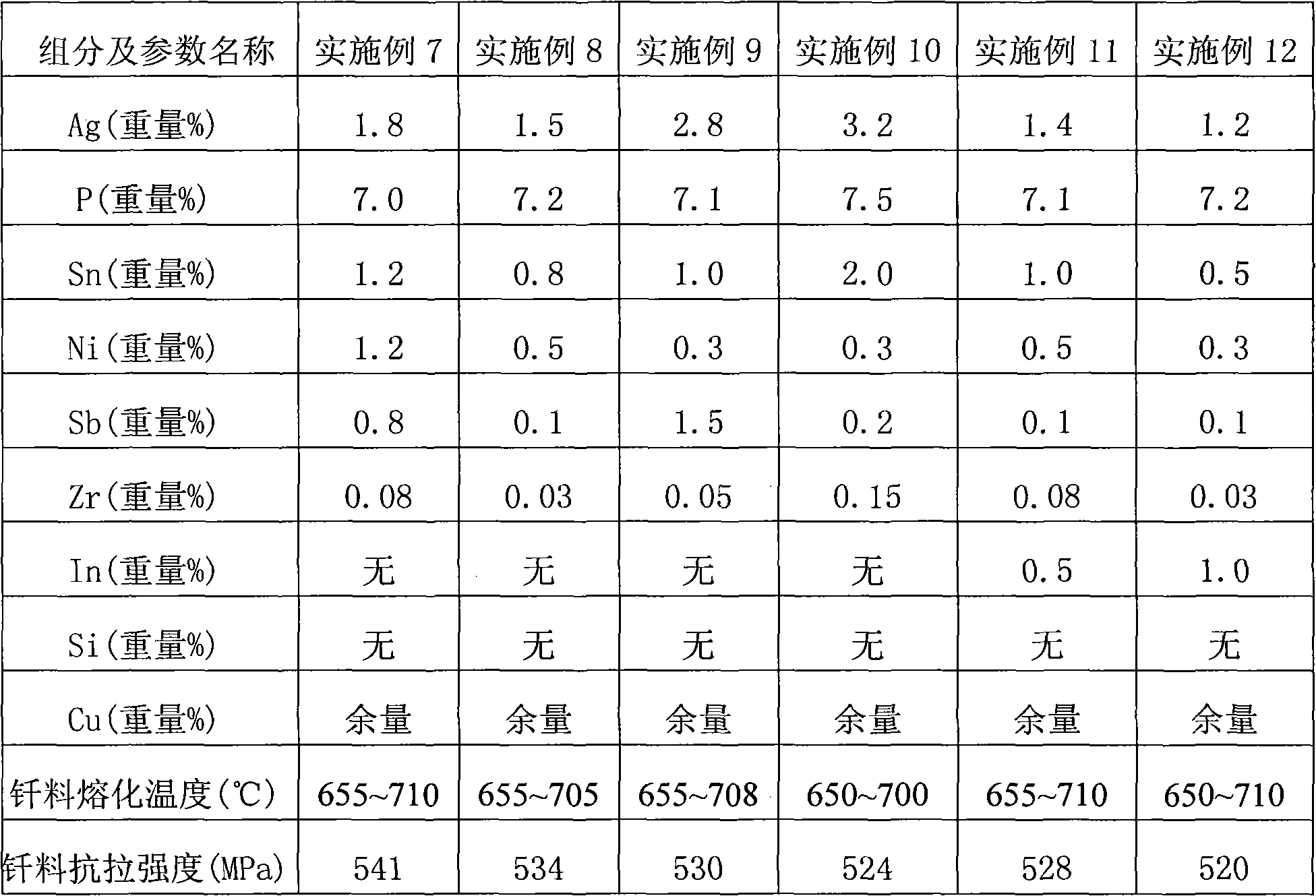

[0024] Table 3 embodiment 13-embodiment 18 related data table

[0025]

[0026] Table 4 embodiment 19-embodiment 24 related data table

[0027]

[0028]

[0029] Table 5 embodiment 25-embodiment 30 related data table

[0030]

[0031]

[0032] Table 6 embodiment 31-embodiment 36 related data table

[0033]

[0034] Table 7 embodiment 37-embodiment 42 related data table

[0035]

[0036]

[0037]Table 1 is the relevant data table of Embodiment 1-Example 6 of the present invention, Table 2 is the relevant data table of Embodiment 7-Example 12 of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com