Handling device for liquor guns of a recovery boiler plant, a recovery boiler plant, and a method in a recovery boiler

A technology for operating devices and recovery boilers, which can be used in injection devices, pulping waste liquid combustion, etc., to solve problems such as dangerous environments, operator exposure, etc., and achieve the effect of the danger of safety personnel being injured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

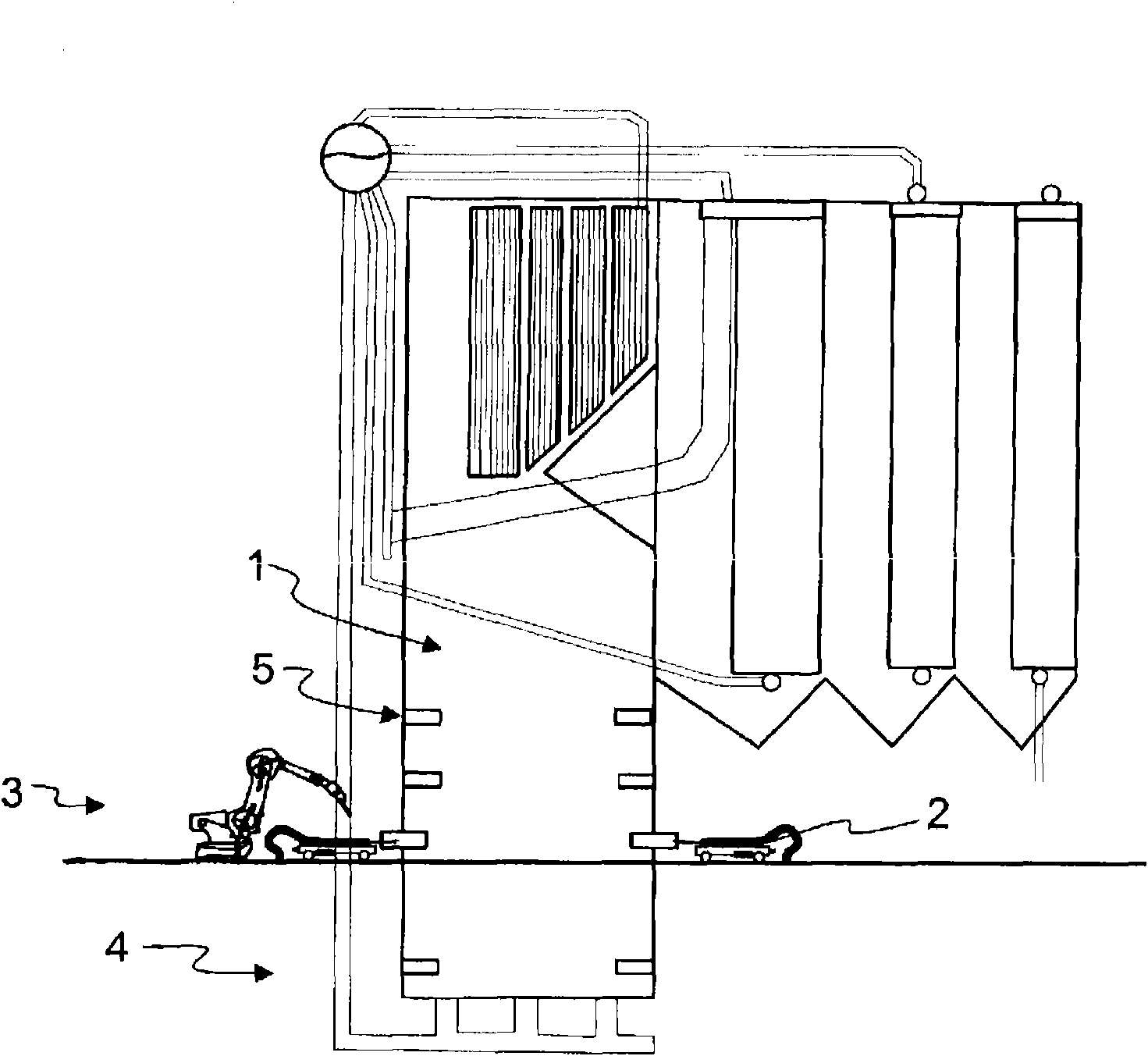

[0050] figure 1 The recovery boiler plant is shown in principle. The plant comprises a furnace 1 to which the black liquor to be burned is fed by a liquor lance 2 . The figure shows the liquid gun area 3 in the lower part of the device. The liquid gun area 3 usually includes the so-called main service platform for using and maintaining the liquid gun 2 . Below the liquid gun area 3 is the smelt spout area 4 . In this embodiment, above the liquid gun area 3 in turn is an air supply platform 5 . Depending on the application, the number and position of the air supply platforms 5 can be different. The different parts of this figure are not marked according to the exact dimensions between each other, because the purpose of this figure is only to show the position of the liquid gun area 3 of the present invention.

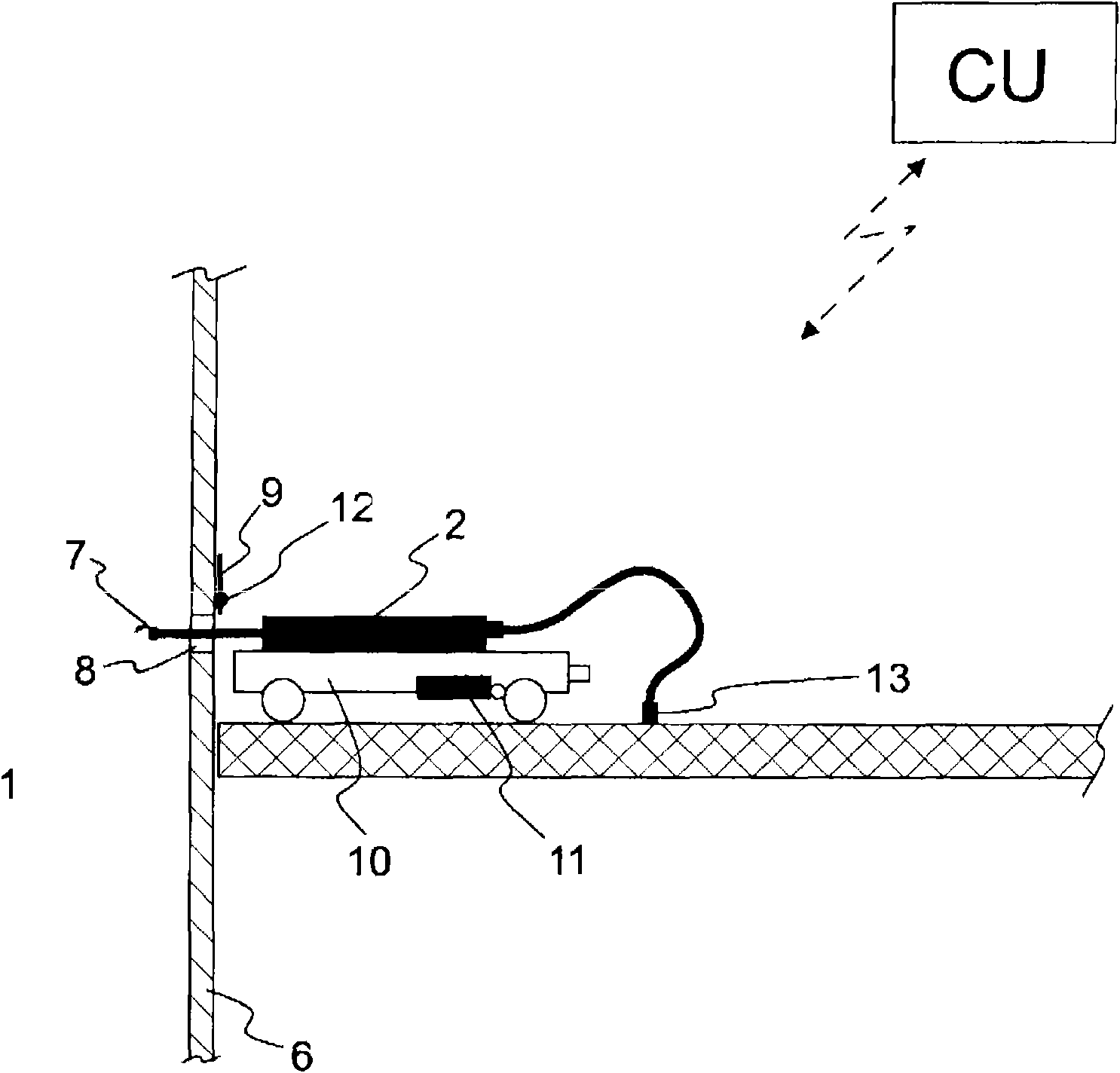

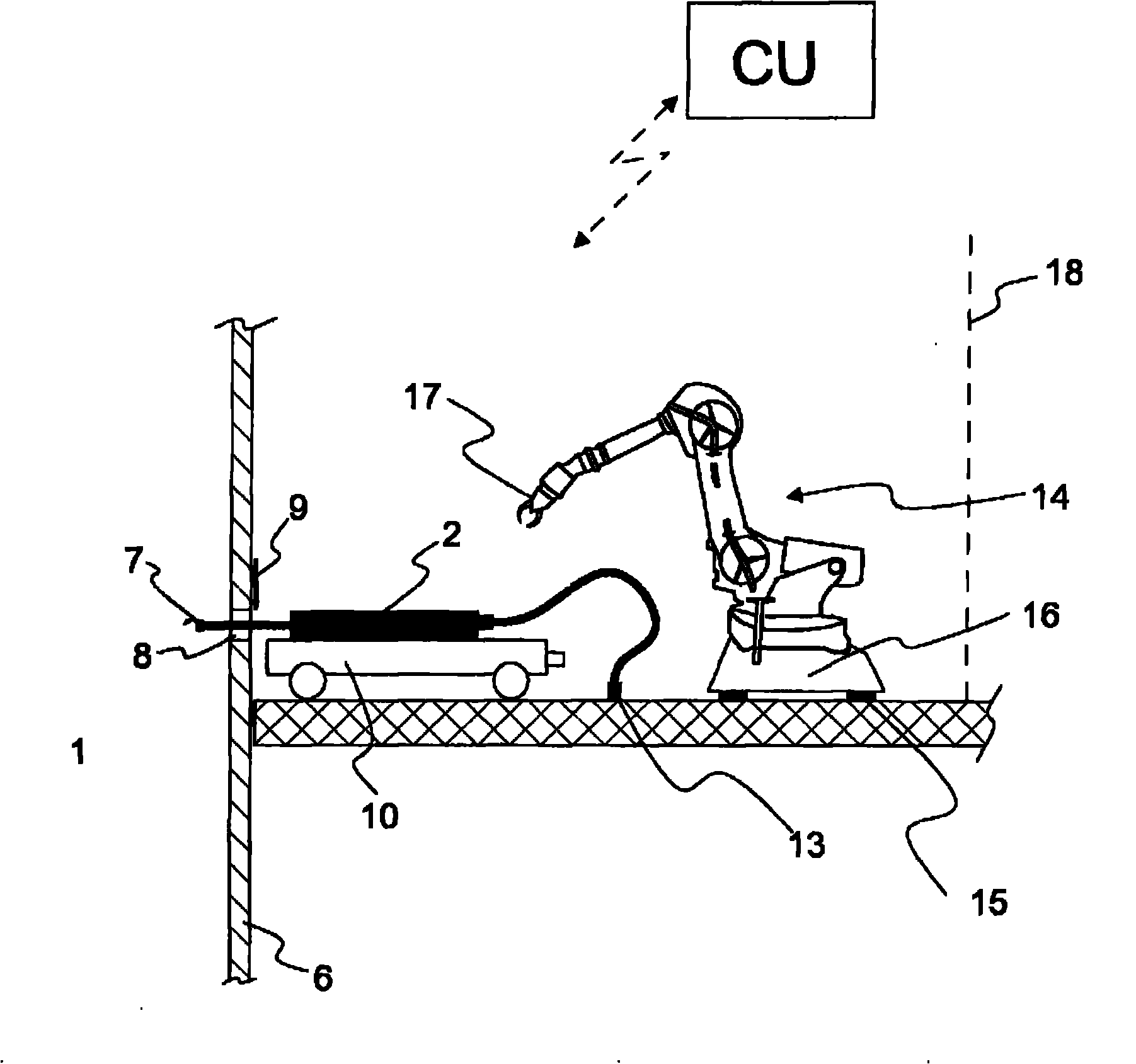

[0051] attached figure 2 Detail of area 3 of the liquid gun is shown. The figure shows the arrangement of the liquid lances 2 in the region adjacent to the wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com