Method of advanced oxidation for NO in flue gas and device thereof

An advanced oxidation and flue gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of no relevant research on exhaust gas, no patent application for NO oxidation by Fenton method, etc. The effect of easy retrofit, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

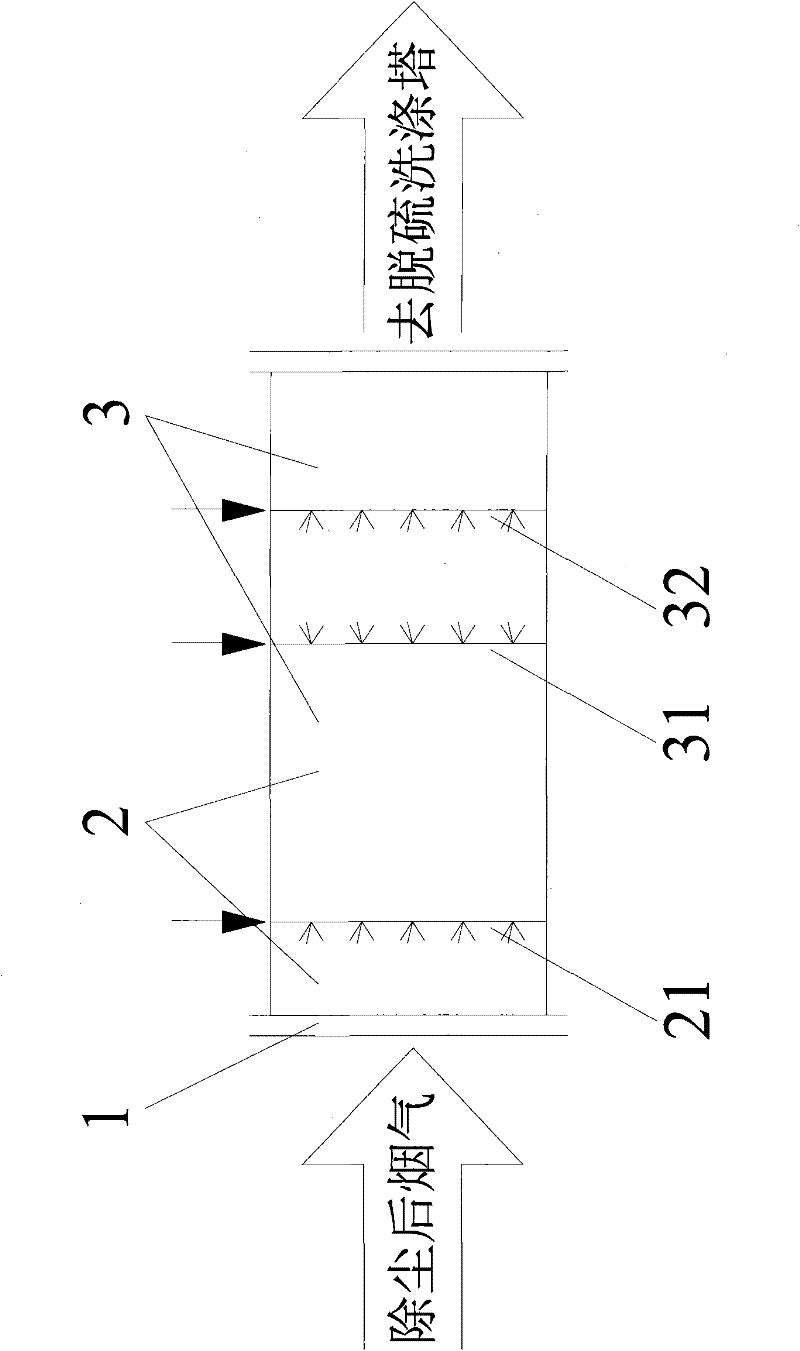

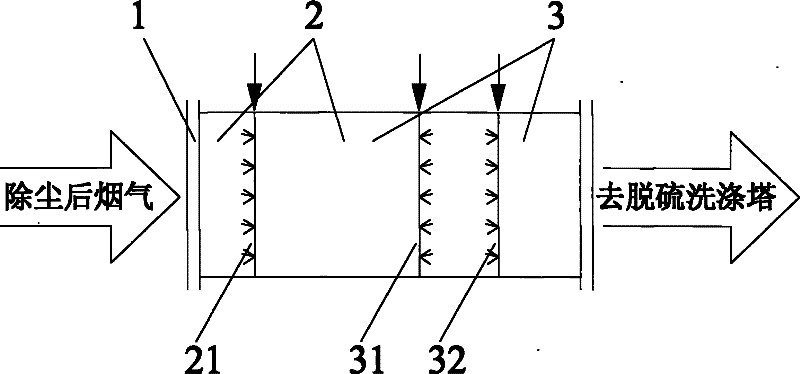

[0022] refer to figure 1 , a method for advanced oxidation of NO in flue gas, the flue gas after dedusting enters the vapor phase advanced oxidation device 1, and includes the following steps in turn: A. flue gas preconditioning: adopting process water spraying device 21 to directly spray process water Reverse spraying on the high-temperature flue gas, the humidity of the flue gas increases to 30%-70%, and the temperature drops to 90-110°C. This step completes the cooling, humidification and conditioning of the flue gas, creating a suitable reaction for the advanced oxidation of NO Environment; B. Vapor Phase Advanced Oxidation: The ferrous salt solution sprayed by the ferrous salt spraying device 31 and the hydrogen peroxide solution sprayed by the hydrogen peroxide spraying device 32 form the gaseous Fenton's reagent, generating a large amount of free radicals with extremely strong oxidation performance OH and HO 2 etc. It can oxidize insoluble NO in the flue gas into high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com