Split type stator coil winding method and winding mold device

A stator coil and winding method technology, applied in the field of AC servo permanent magnet synchronous motor production, can solve the problems of unstable motor performance, high labor intensity of workers, and many motor joints, and achieve reduced labor intensity, simple structure, and guaranteed tightness Effect of Degree Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The following takes the motor EM180ST01 as an example to illustrate the processing steps:

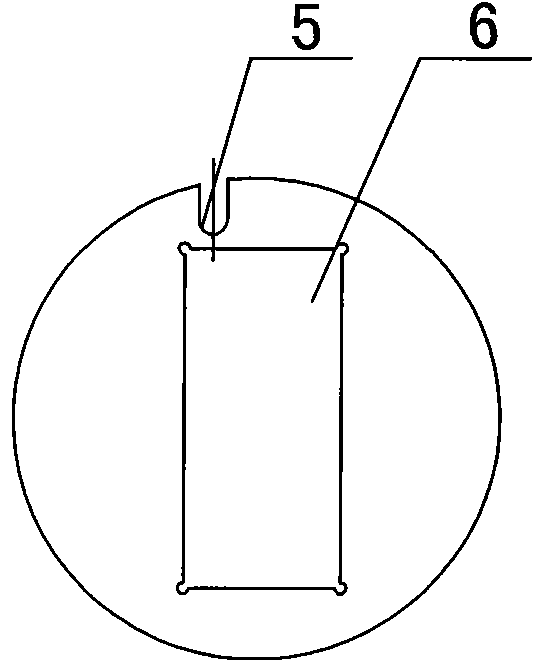

[0035] The AC servo permanent magnet synchronous motor model EM180ST01 has a split stator core composed of 18 split stator core teeth, and each phase has 6 split stator core teeth. The winding diagram is as follows Figure 5 As shown, the electromagnetic scheme is: iron core length L=120mm; wire gauge: Parallel winding; number of turns: 20 turns.

[0036] The winding process of 6 stator tooth coils in each phase of EM180ST01 motor:

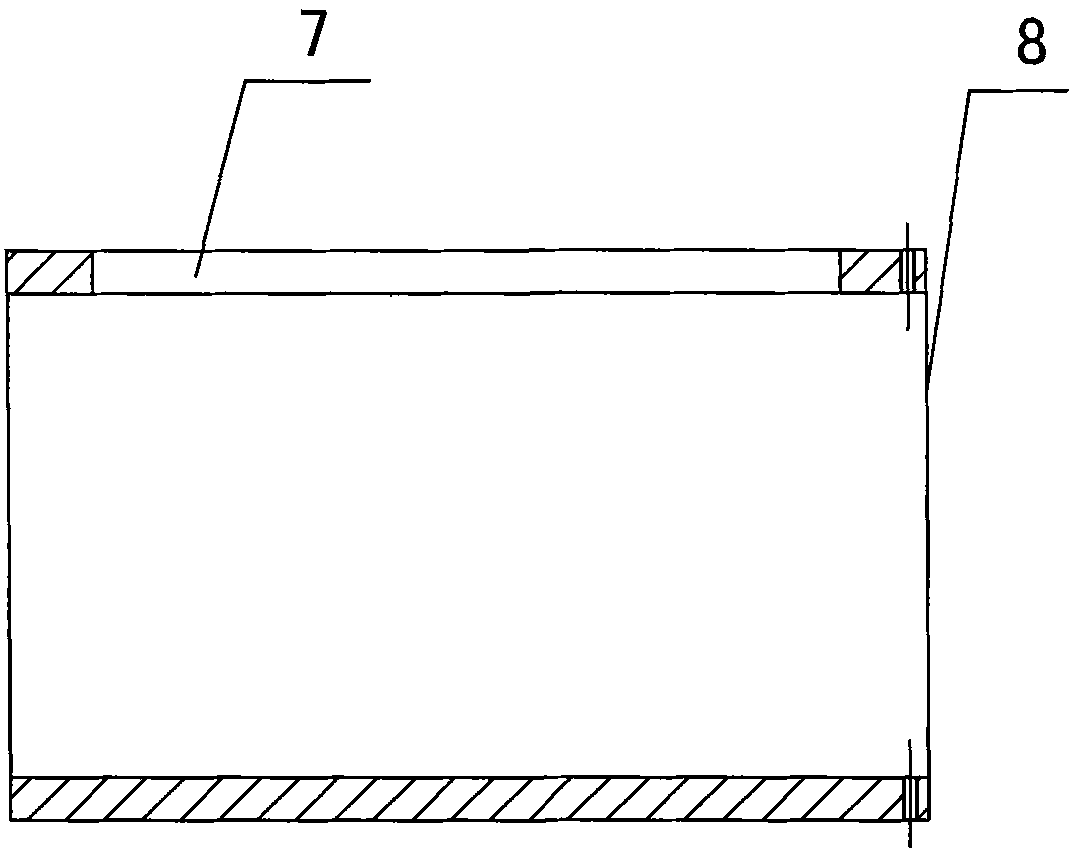

[0037] 1. Wrap F-slot insulating paper in the tooth slots of the split stator core teeth, and buckle the ends of the core teeth with insulating end plates.

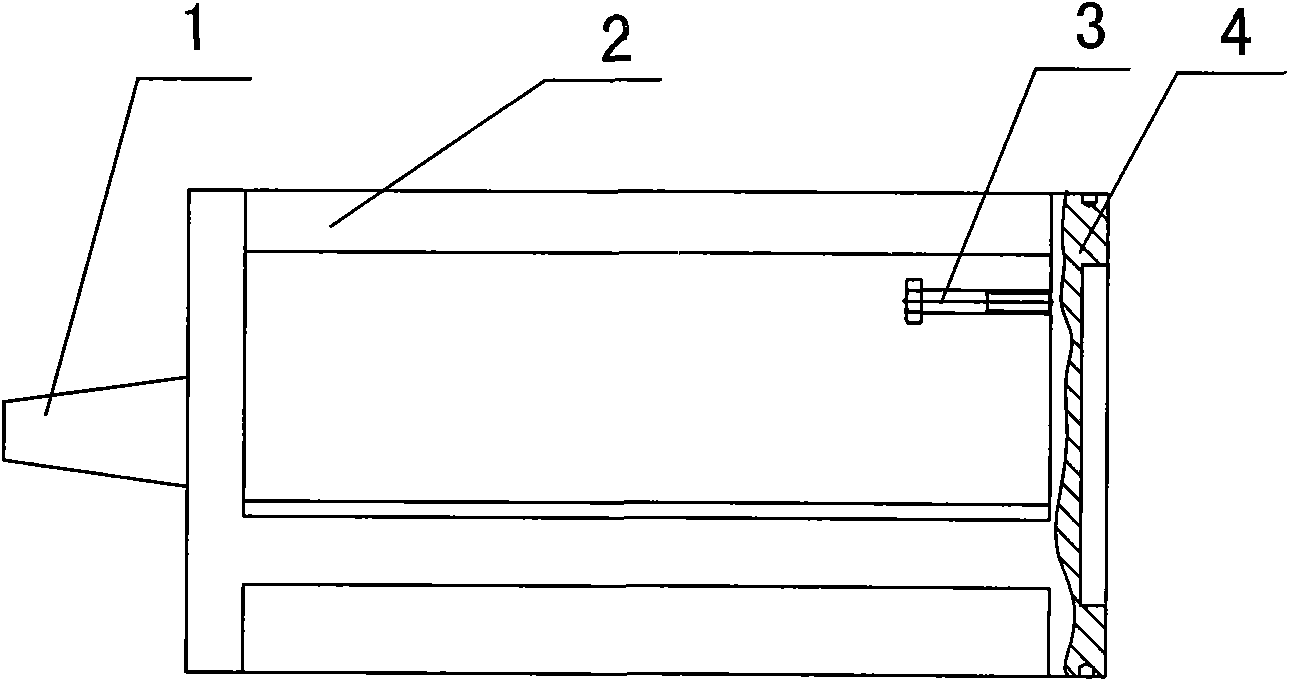

[0038] 2. Put the outer sleeve 8 on the core support 2, and the core support 2 of the winding die device and the first group stator core tooth tip are tightly mounted on the winding machine. The beginning of the winding is drawn from the wire arranging die and passed through the groove of the core supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com