Preparation method of Cu doped p type ZnO thin film

A thin-film, p-type technology, applied in the field of preparing p-type zinc oxide thin films, can solve the problems of large atomic size, low ionization energy, and difficulty in achieving ZnOp-type doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

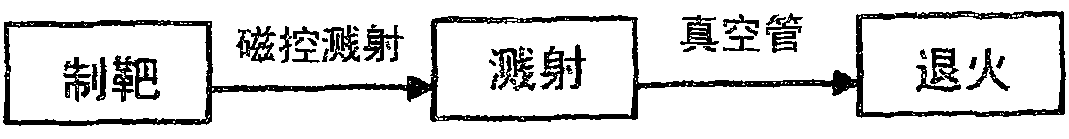

[0016] see figure 1 Shown, the present invention provides a kind of preparation method of Cu-doped p-type ZnO film, comprises the steps:

[0017] Step 1: Using radio frequency magnetron sputtering method; the sample growth is a self-designed JB-650 ultra-high vacuum multi-target magnetron sputtering instrument, the power supply mode is radio frequency; there are four sputtering in the reaction chamber The diameter of the shooting target reaches 85mm, and the substrate can be rotated at the same time to ensure the uniform thickness of the film; the targets used for sputtering growth films are divided into two targets, A and B, and the A target is made of ZnO powder with a purity of 99.99% and high-purity The Cu powder is uniformly mixed and pressed in a copper round holder, and the molar ratio of Cu element in the target is 2%. The B target is only pressed from ZnO powder with a purity of 99.99%. The purpose of using two targets is to obtain samples with different Cu doping c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com