Overdosed esterification production technology for n-octyl gallate

A technology for producing n-octyl gallate, which is applied in the field of preparing n-octyl gallate, can solve the problems of affecting the effect of esterification reaction and difficult separation of water, shorten the time of esterification reaction, cause no environmental pollution, reduce The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

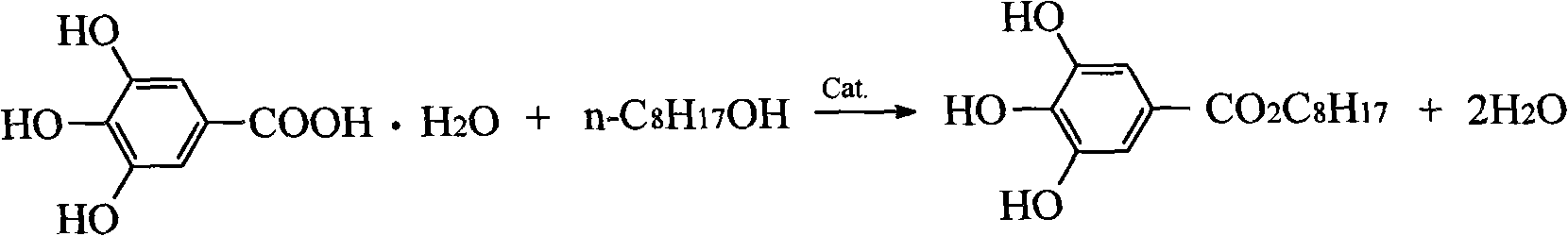

Image

Examples

Embodiment 1

[0025] Add 100g of industrial gallic acid, 250ml of n-octanol into a beaker, stir, add 7g of methanesulfonic acid catalyst, control the temperature at 80℃ to react for 2 hours, cool to 20℃ and filter, the filtrate is evaporated and concentrated under reduced pressure, recovered and evaporated The n-octanol solvent. After the product was recovered by alcohol, 400ml of cyclohexane solvent (99.0%) was added as a solvent for recrystallization. After filtration and washing with water, the filtrate was recrystallized by adding 400ml of cyclohexane solvent again, and the filtrate was filtered twice to recover the solvent. Filter, wash the filtered material until the pH is 6.0-7.0, take the filtrate and vacuum dry (60°C) to obtain 73.3 g of n-octyl gallate finished product, with a content of 99.2%.

Embodiment 2

[0027] Add 100g of industrial gallic acid, 500ml of n-octanol into a beaker, stir, add 7g of methanesulfonic acid catalyst, control the temperature at 80℃ to react for 2 hours, cool to 20℃ and filter, the filtrate is evaporated and concentrated under reduced pressure, recovered and evaporated The n-octanol solvent. After the product was recovered by alcohol, 400ml of cyclohexane solvent (99.0%) was added as a solvent for recrystallization. After filtration and washing with water, the filtrate was recrystallized by adding 400ml of cyclohexane solvent again, and the filtrate was filtered twice to recover the solvent. Filter, wash the filtered material until the pH is 6.0-7.0, take the filtrate and vacuum dry (60°C) to obtain 87.8 g of n-octyl gallate finished product, with a content of 99.3%.

Embodiment 3

[0029] Add 100g of industrial gallic acid, and 750ml of n-octanol into a beaker, stir, add 7g of methanesulfonic acid catalyst, control the temperature at 80℃ to react for 2 hours, cool to 20℃ and filter, the filtrate is evaporated and concentrated under reduced pressure, recovered and evaporated The n-octanol solvent. After the product is recovered by alcohol, 400ml of cyclohexane (99.0%) is added as a solvent for recrystallization. After filtration and washing with water, the filtrate is recrystallized by adding 400ml of cyclohexane solvent again. The filtrate after twice filtration is concentrated to recover the solvent and filter. , Wash the filtered material until the pH is 6.0-7.0, take the filtered material and vacuum dry (60°C) to obtain 78.1 g of n-octyl gallate finished product with a content of 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com