Closed type drying device

A drying device and drying technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of environmental damage, environmental pollution, condensation, etc., and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

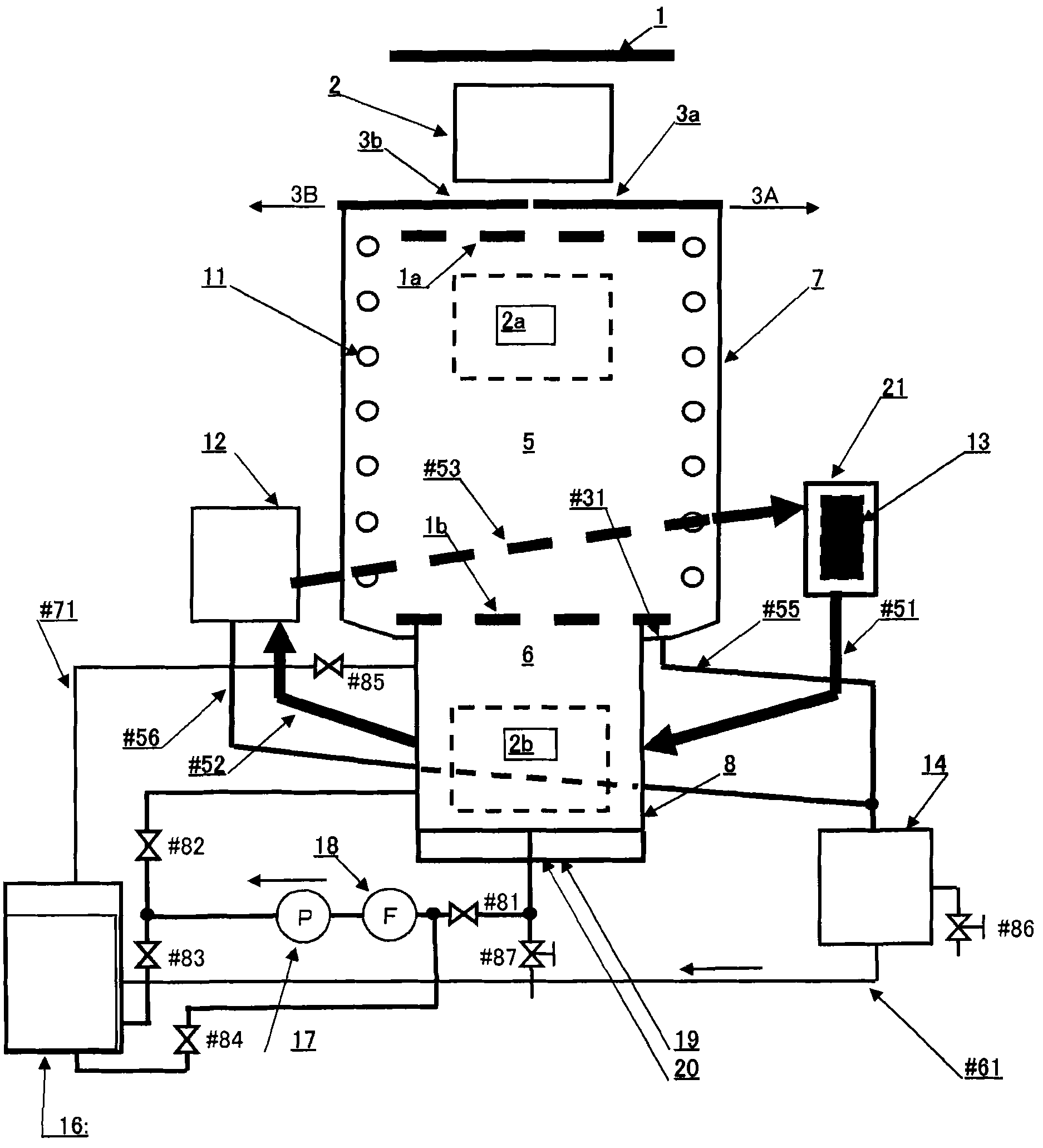

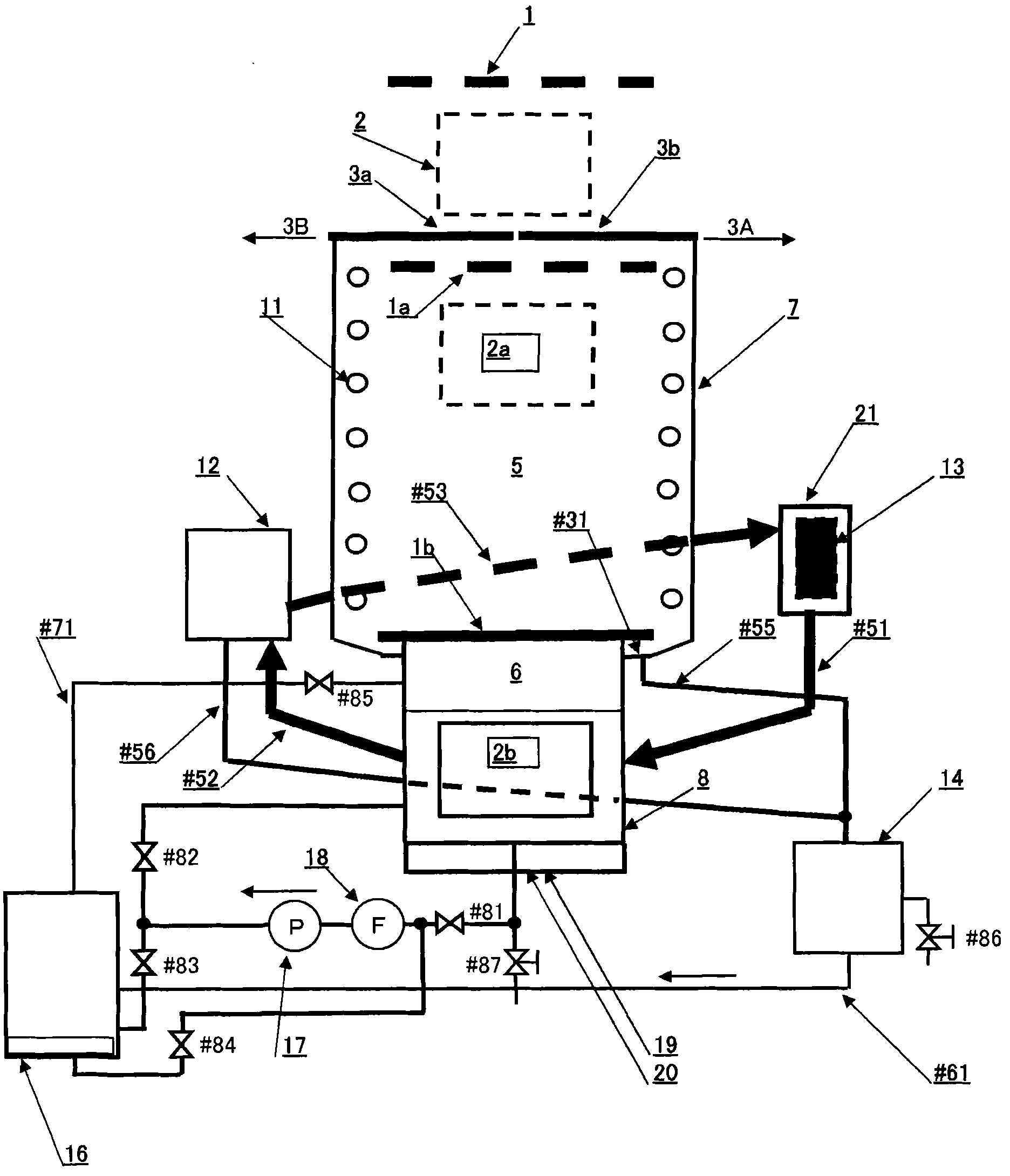

[0051] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0052] figure 1 The equipment is aimed at removing a small amount of oil cleaning objects, and an additional simple distiller is added. The present invention is a general equipment that adds a distillation device separately, because the boiling point temperature of the solvent is relatively low, and the solvent used is HFC-4310, HFC-365, HCFC-225, HFE-7000, equipment designed for less oil dissolution.

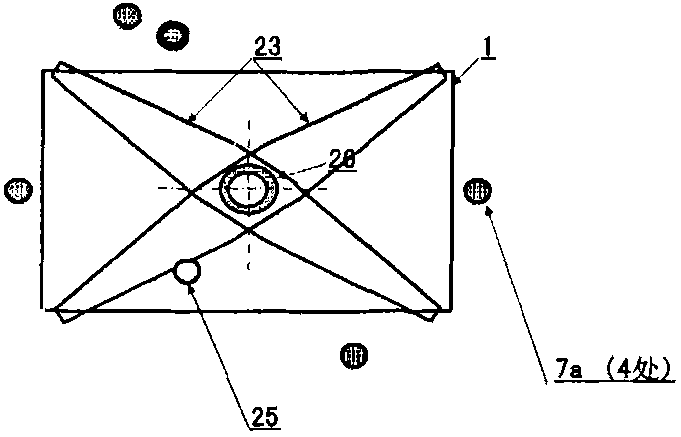

[0053] 1. It is the cleaning tank cover 1, it is the driving mechanism, and it is a frame that can move up and down.

[0054] The slot cover 1 has a first position and a second position. The first position is the position state where the tank cover 1 is at the first lowered position to 1b. The second position is the position of 1a, which is from the 1b state position of the first position from bottom to top to the state position of 1a.

[0055] In the state where the lowered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com