High-strength compound sand-prevention screen pipe and manufacture method thereof

A sand control screen and sand control technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well parts, etc., can solve the problems of easy accumulation of spun yarn, low internal pressure resistance, mesh damage strength, etc., to increase oil and gas flow The effect of large flow area, strong anti-deformation ability and large flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

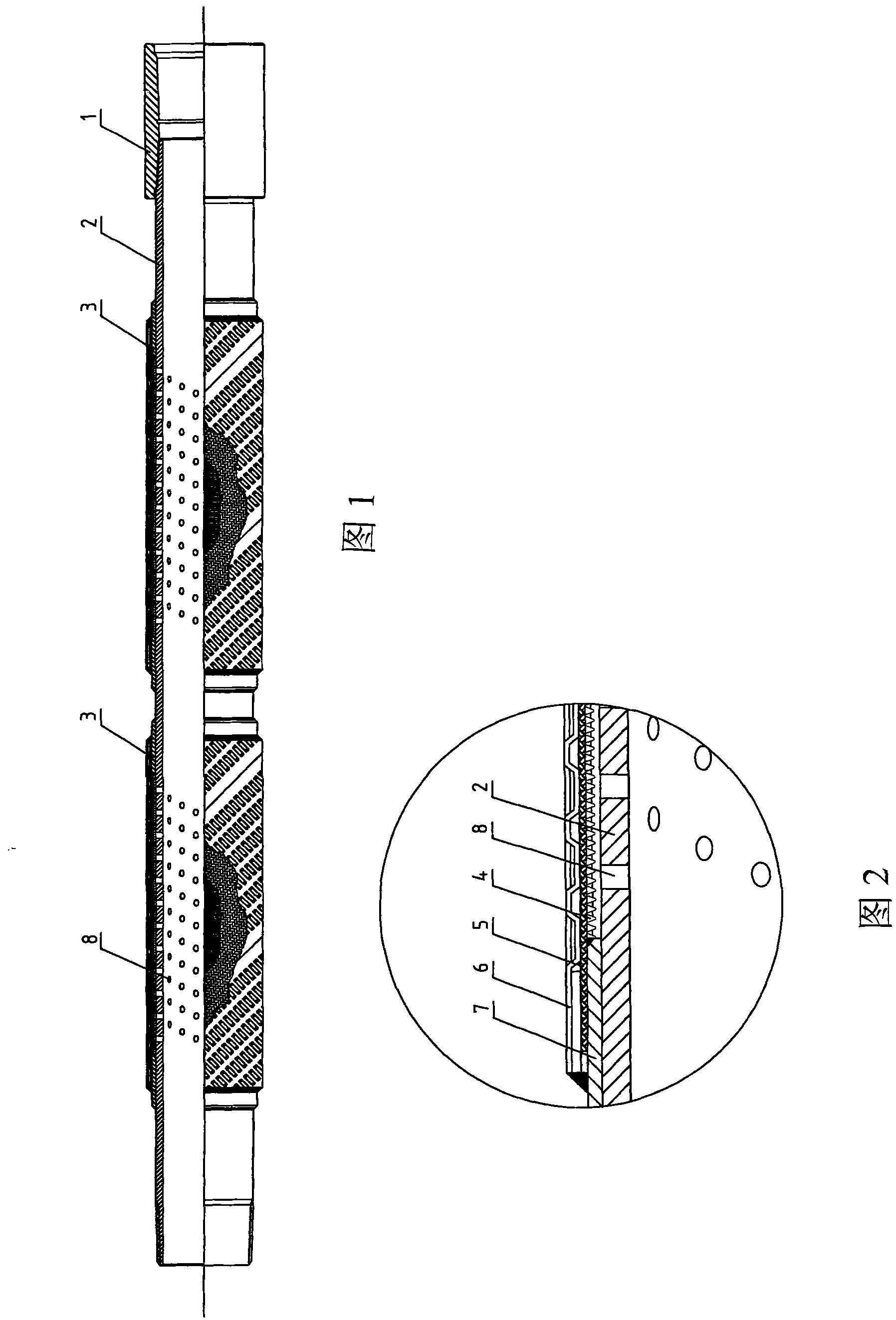

[0028] A typical embodiment of the present invention includes: a coupling 1, a base pipe 2 and a composite sand control filter sleeve 3, such as figure 1 , 2 shown.

[0029] Coupling 1 is a pipe joint with internal threads at both ends, and connects two base pipes 2 with internal threads, which belongs to the prior art;

[0030] The base pipe 2 is provided with a plurality of evenly distributed flow holes 8 on the cylindrical surface of effective one or two lengths (depending on the length of the base pipe 2). The diameter of the flow holes 8 is between 8mm and 15mm. There is an external thread at both ends, one end is connected to the collar 1, and the other end is used for connecting other components or tools downhole.

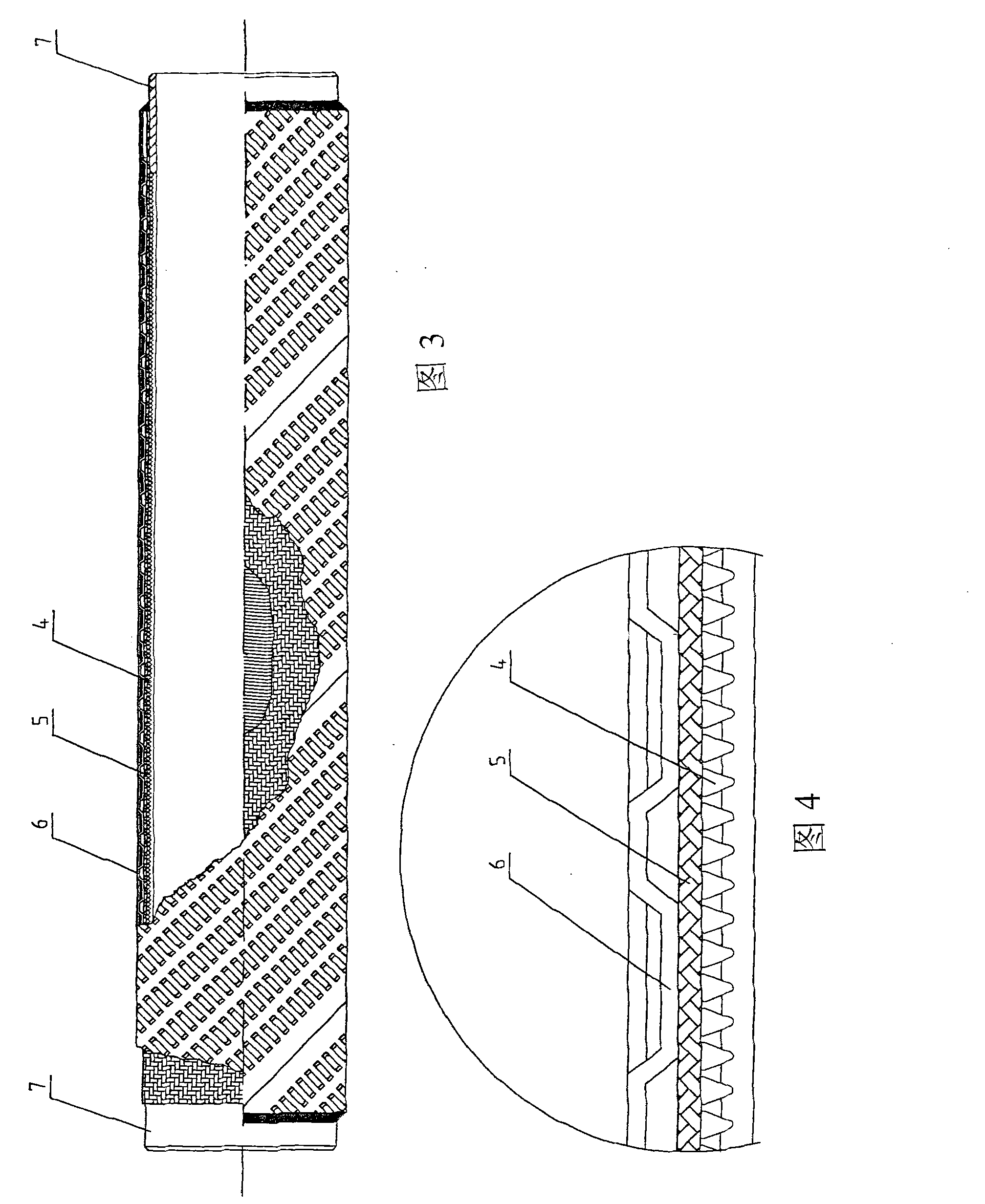

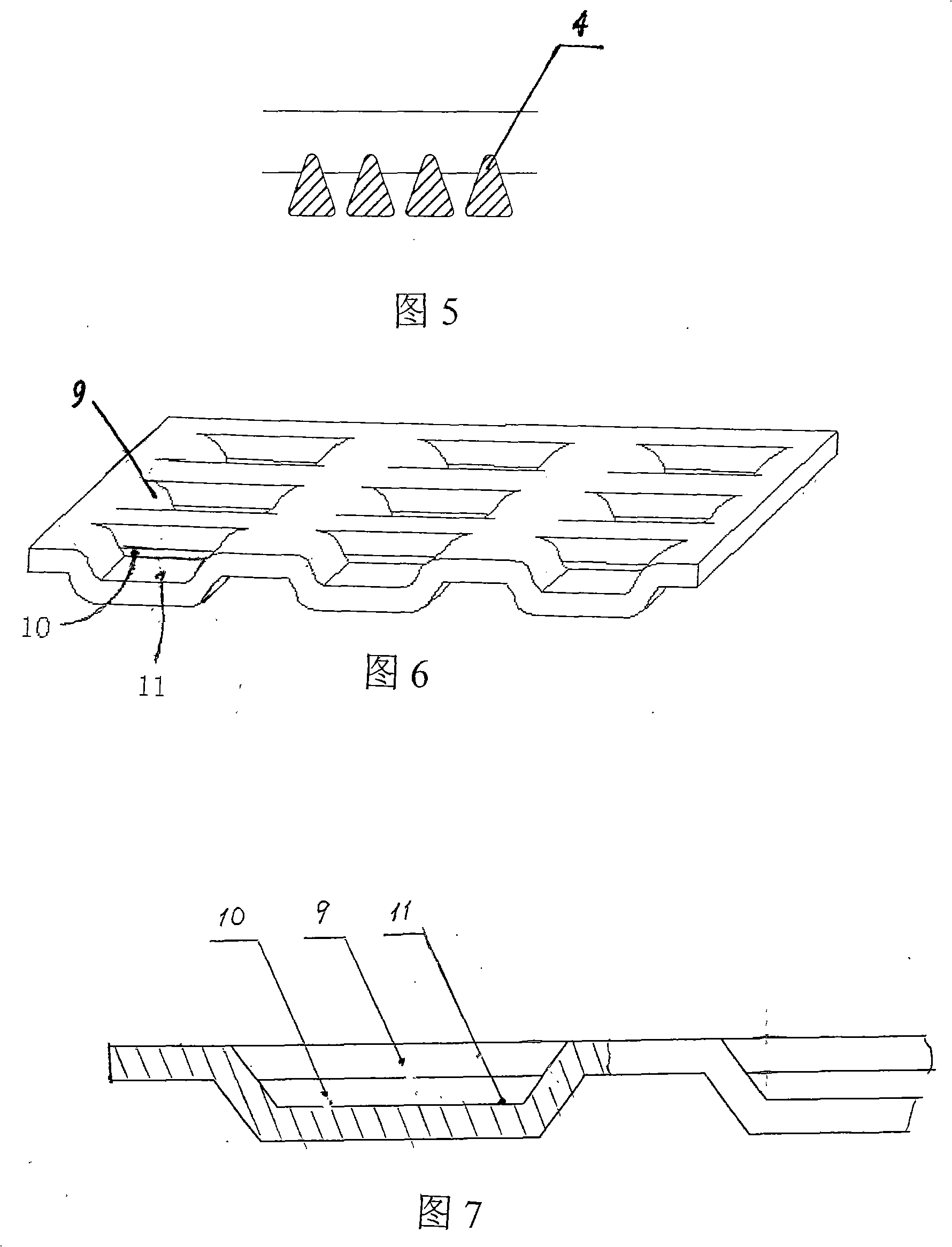

[0031] The composite sand control filter sleeve 3 is composed of an outer protective sleeve 6, a reverse twill metal mesh layer 5, a triangular wire-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com