Washing dispersion machine of degummed ramie fiber

A dispersing machine and degumming technology, applied in fiber processing, mechanical processing, textile and papermaking, etc., can solve the problems of low work efficiency, high labor intensity, high water consumption, etc., and achieve water recycling and reuse, high work efficiency, work low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is specifically realized like this:

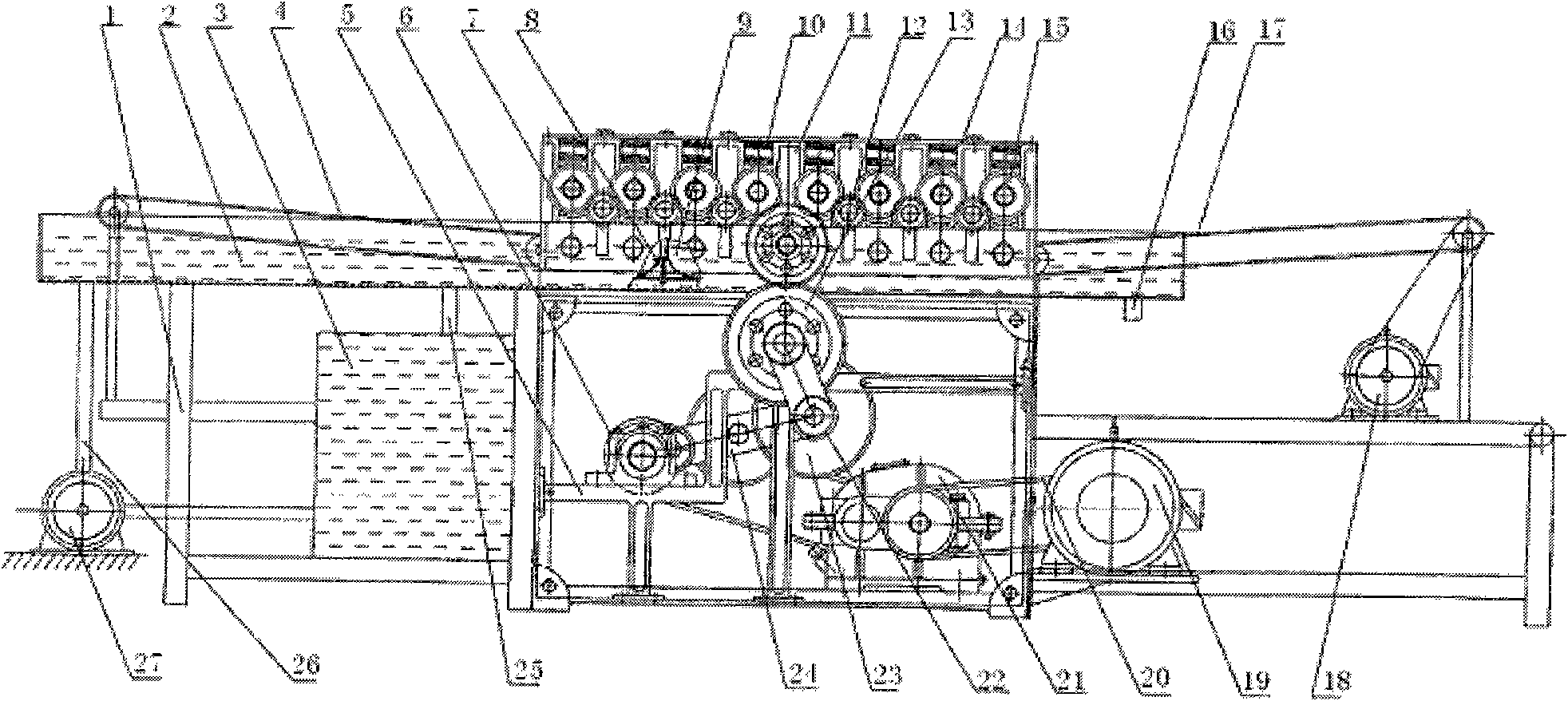

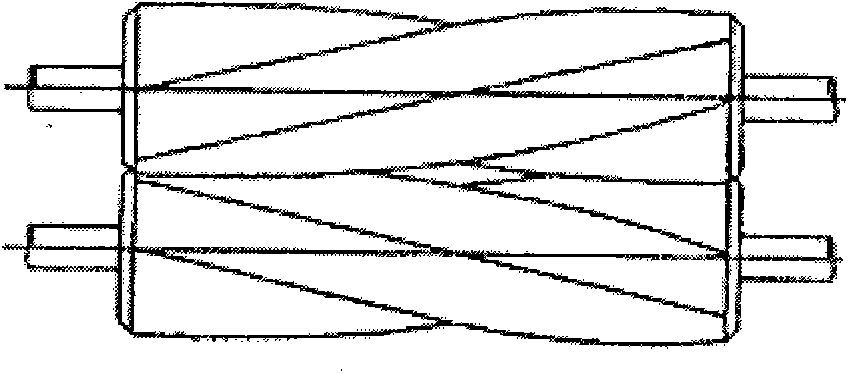

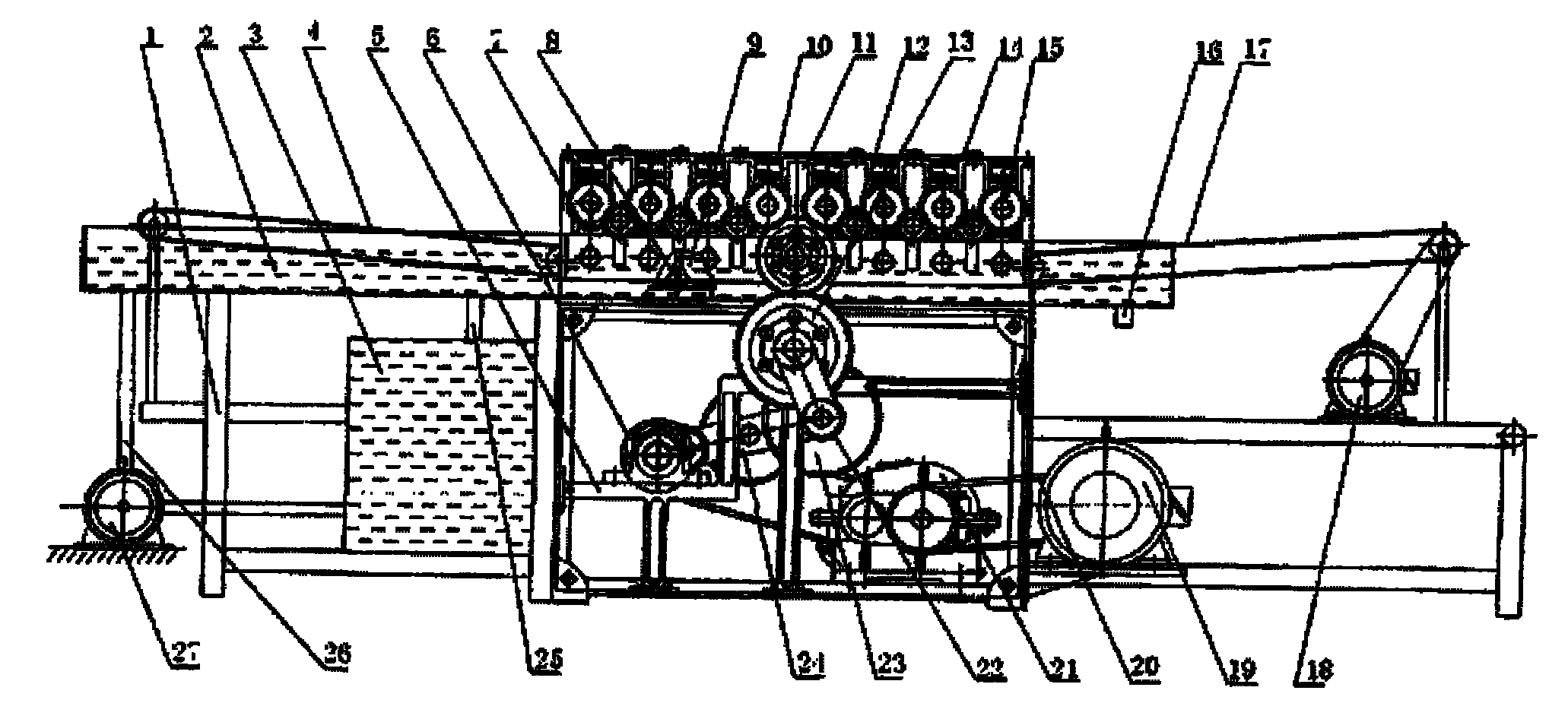

[0020] The ramie degumming fiber washing and dispersing machine, the structural features include a frame 1, a water tank 2 positioned on the frame, a hemp feeding curtain 4 and a hemp outlet curtain 17 located at both ends of the water tank, a water storage tank 3 under the water tank, through pipes and The circulating water pump is connected to the water inlet and outlet of the water tank; there are several groups of concave roller brackets 11 in the water tank, and there are several pairs of driving rollers 7 and driven rollers 9 on the brackets, and the driving rollers are meshed with the driven rollers; There is a washing spray gun 8 between the rollers; the driving roller is connected with the roller transmission gear 15, the transmission gear 15 is connected with the bridge gear 12 and the gear 13, and the gear 13 is composed of the intermediate wheel 22, the differential gear train 23 and the crank connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com