Method for preparing large-area high-performance color stainless steel by laser oxidation coloring

A stainless steel, large-area technology, applied in coating, metal material coating process, solid-state diffusion coating, etc., to achieve the effect of suitable for mass production, good reproducibility, and strong bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

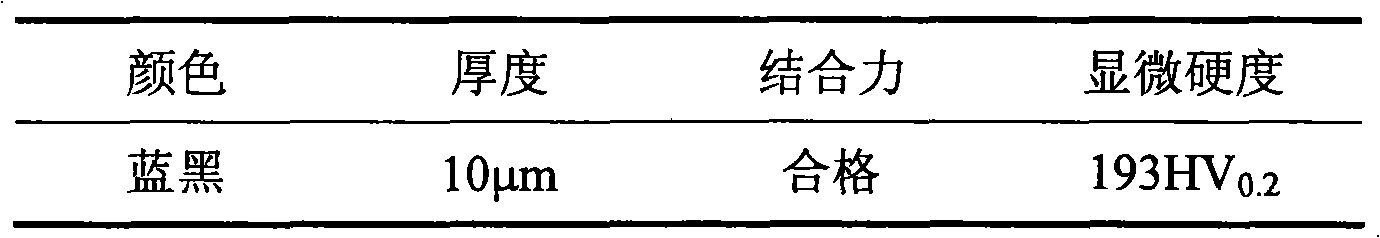

Embodiment 1

[0025] 1. Steps

[0026] 1) Grind the wire-cut stainless steel on a pre-grinder to a roughness of Ra3.0μm with No. 280-1000 sandpaper, and then use metallographic sandpaper to finely grind the stainless steel after the above treatment to a roughness of Ra1.5μm, and then use alcohol Wash in ultrasonic wave at 20°C for 10 minutes, and dry quickly in hot air after taking it out;

[0027] 2) Place the stainless steel treated in step 1) on the X-Y computer-controlled workbench, and carry out laser oxidation and coloring treatment in an environment with an oxygen flow rate of 1L / min: the X-Y computer-controlled workbench moving speed is 2mm / s, The continuous laser power is 50W, the laser rectangular spot size is 0.5mm×1mm, the laser action time is 1s, the defocusing distance is 0.01mm, and the spot overlap rate is 10%, and a blue-black oxide film on the stainless steel surface is obtained;

[0028] 3) Wash the colored stainless steel treated in step 2) with alcohol in an ultrasonic...

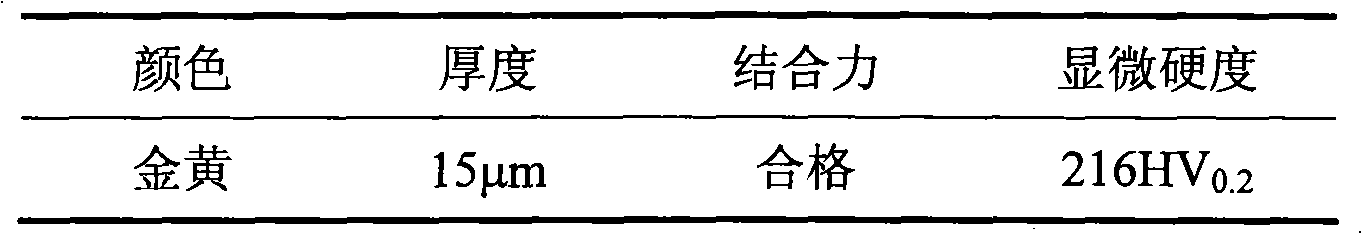

Embodiment 2

[0035] 1. Steps

[0036]1) Grind the wire-cut stainless steel on a pre-grinding machine to a roughness of Ra2.0μm with 280-1200 sandpaper, and then use metallographic sandpaper to finely grind the stainless steel after the above treatment to a roughness of Ra1.0μm, and then use alcohol Wash in ultrasonic at 30°C for 15 minutes, and dry quickly in hot air after taking it out;

[0037] 2) Place the stainless steel treated in step 1) on the X-Y computer-controlled workbench, and carry out laser oxidation and coloring treatment in an environment with an oxygen flow rate of 2L / min: the X-Y computer-controlled workbench moving speed is 5mm / s , the continuous laser power is 150W, the laser rectangular spot size is 1mm×1mm, the laser action time is 2s, the defocusing distance is 5mm, and the spot overlap rate is 20%, and a golden oxide film on the surface of stainless steel is obtained;

[0038] 3) Wash the colored stainless steel treated in step 2) with alcohol for 15 minutes in an ...

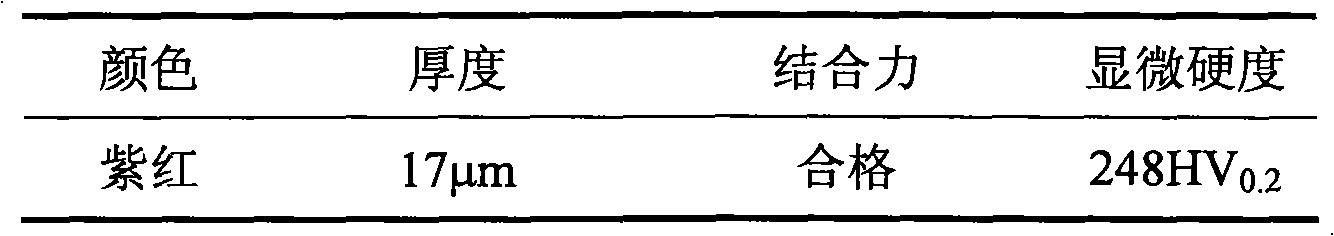

Embodiment 3

[0044] 1. Steps

[0045] 1) Grind the wire-cut stainless steel on a pre-grinding machine to a roughness of Ra1.5μm with sandpaper No. Wash in ultrasonic wave at 40°C for 20 minutes, and dry quickly in hot air after taking it out;

[0046] 2) Place the stainless steel treated in step 1) on the X-Y computer-controlled workbench, and carry out laser oxidation and coloring treatment in an environment with an oxygen flow rate of 3L / min: the X-Y computer-controlled workbench moving speed is 10mm / s, The continuous laser power is 300W, the laser rectangular spot size is 1.5mm×2mm, the laser action time is 3s, the defocusing distance is 5mm, and the spot overlap rate is 30%, and a bright purple red stainless steel surface oxide film is obtained;

[0047] 3) Wash the colored stainless steel treated in step 2) with alcohol for 20 minutes in an ultrasonic wave at 40°C, take it out, and quickly dry it in hot air to obtain a clean, stable, and high-performance colored stainless steel.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com