Polymer film sound absorbing material and preparation method thereof

A technology of polymer film and sound-absorbing material, applied in the field of polymer film sound-absorbing material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: prepare polyaniline film

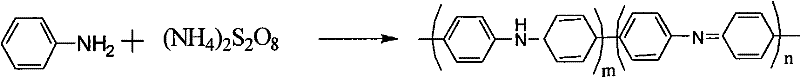

[0032] The synthetic reaction equation of basic polyaniline:

[0033]

[0034] Preparation of conductive polyaniline: Add aniline and hydrochloric acid solution in proportion to the three-neck flask, and slowly drop the hydrochloric acid solution of ammonium persulfate into the solution in an ice-water bath under high-speed stirring. After dropping, keep the reaction temperature at 0°C and react for 7-12 hours. After standing still for 12-16 hours, filter and wash until neutral, and vacuum-dry for use.

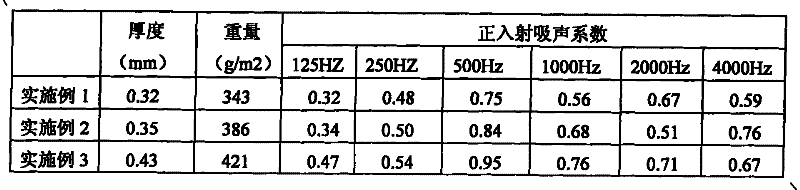

[0035] Therefore, take 10 parts of polyaniline, 2 parts of epoxy resin, 1 part of polyamide resin, 60 parts of N-methylpyrrolidone, and 20 parts of methyl ethyl ketone, make a slurry with ultrasonic waves, and then apply it on nylon cloth and dry it. Film with a thickness of 0.32 mm. The test results of the sound absorption coefficient are shown in Table 1.

Embodiment 2

[0036]Embodiment 2: prepare polyaniline graphite film

[0037] The preparation of conductive polyaniline is the same as example 1. Take 10 parts of polyaniline polymer, 2 parts of epoxy resin, 1 part of polyamide resin, 60 parts of N-methylpyrrolidone, and 20 parts of methyl ethyl ketone according to the ratio of polyaniline: nano graphite = 1: 0.2, and use ultrasonic to make a slurry , and then coated on nylon cloth, dried to make a film with a thickness of 0.35 mm. The sound absorption coefficient test results are shown in Table 1.

Embodiment 3

[0038] Embodiment 3: prepare polyaniline graphite film

[0039] The preparation of conductive polyaniline is the same as example 1. Take 10 parts of polyaniline polymer, 2 parts of epoxy resin, 1 part of polyamide resin, 60 parts of N-methylpyrrolidone, and 20 parts of methyl ethyl ketone according to the ratio of polyaniline: nanographite = 1:0.3, and use ultrasonic waves to make a slurry , and then coated on nylon cloth, dried to make a film with a thickness of 0.43 mm. The sound absorption coefficient test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com