Low-frequency sound-absorbing rubber-based composite material and preparing method thereof

A technology of sound-absorbing rubber and composite material, which is applied to low-frequency sound-absorbing materials and the fields of their preparation and application, can solve problems such as poor low-frequency sound-absorbing performance, and achieve the effects of good sound-absorbing performance, good economic benefits, and a simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A low-frequency sound-absorbing rubber-based composite material includes EPDM rubber and kapok fiber, wherein the mass ratio of EPDM rubber and kapok fiber is 100:10.

[0035] The above-mentioned preparation method of low-frequency sound-absorbing rubber-based composite material, the specific steps are:

[0036] The first step: mixing: keep the temperature of the rollers on the double-roller mill at room temperature, add 100 parts by mass of EPDM between the rollers on the double-roller mill, and then add 10 parts by weight to the rubber The kapok fiber is mixed with EPDM rubber and kapok fiber. The mixing temperature is 40°C and the mixing time is 20 minutes. Due to the difference in the surface speed of the two rollers, the cutter is used for manual auxiliary mixing. After mixing and mixing uniformly, peel off the mixed material from the roller, and then cut it into mixed granules for hot pressing;

[0037] The second step: hot press molding: spread the mixed scraps in the ...

Embodiment 2

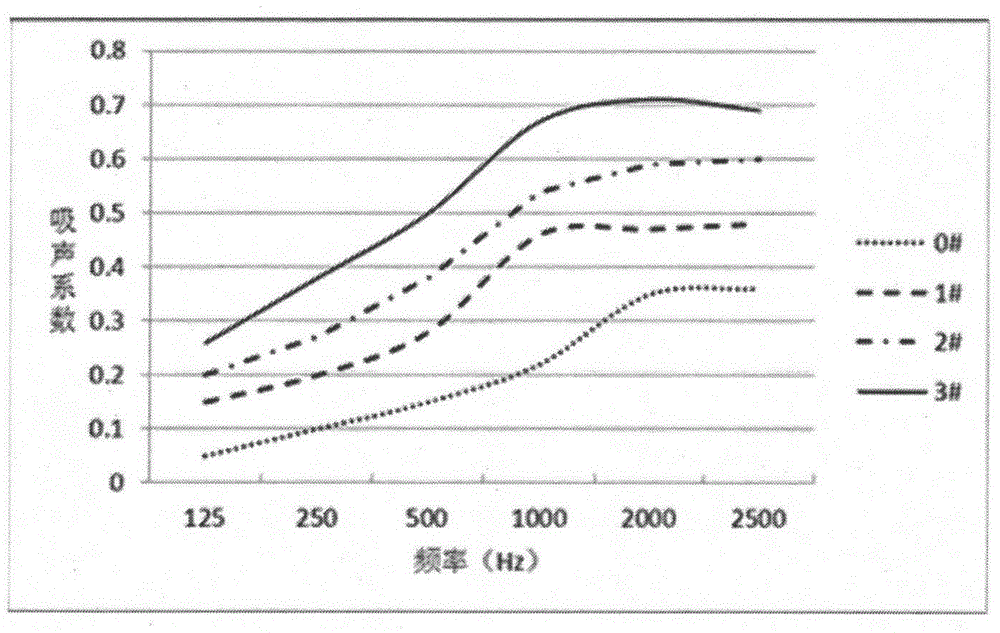

[0039] A low-frequency sound-absorbing rubber-based composite material, comprising EPDM rubber and kapok fiber, wherein the mass ratio of the EPDM rubber and the kapok fiber is 100:10, and the thickness of the low-frequency sound-absorbing rubber-based composite material It is 3mm. Composite material density is 17.9g / cm 3 . (See attached sound absorption effect figure 1 Zhong 2#)

[0040] The preparation method of the above-mentioned low-frequency sound-absorbing rubber-based composite material is the same as that of Example 1.

Embodiment 3

[0042] A low-frequency sound-absorbing rubber-based composite material includes EPDM rubber, kapok fiber and zeolite powder, wherein the mass ratio of EPDM rubber, kapok fiber and zeolite powder is 100:10:20.

[0043] The above-mentioned preparation method of low-frequency sound-absorbing rubber-based composite material, the specific steps are:

[0044] The first step: mixing: keep the temperature of the rollers on the double-roller mill at room temperature, add 100 parts by mass of EPDM between the rollers on the double-roller mill, and then add 10 parts by weight to the rubber The kapok fiber is mixed with EPDM rubber and kapok fiber. The mixing temperature is 40°C and the mixing time is 20 minutes. Due to the difference in the surface speed of the two rollers, the cutter is used for manual auxiliary mixing. Mix uniformly, add 20 parts by mass of zeolite powder to the mixture, and mix again. The temperature of the second mixing is 40°C, the mixing time is 20 minutes, and the cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com