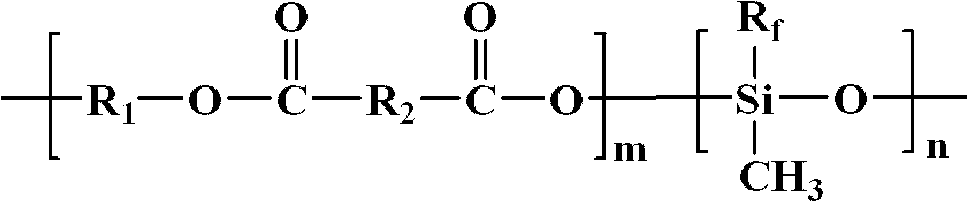

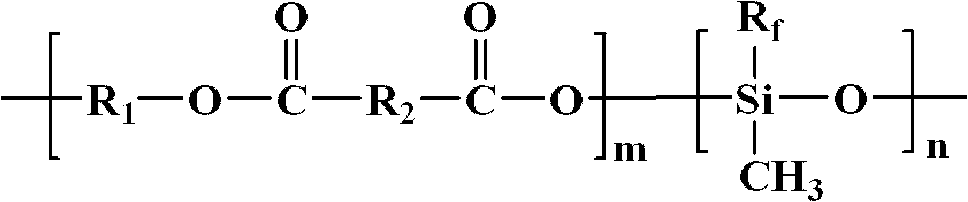

Hydrophobic modified polyester and preparation method thereof

A hydrophobic modification, polyester technology, applied in polyester coatings, coatings and other directions, can solve the problems of high cost and large consumption, and achieve the effects of simple operation, simple preparation method, and easy industrial-scale implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Bishydroxyethyl terephthalate oligomer with a degree of polymerization of 2 to 4, ethylene glycol, and a fluorine-containing silicon modifier with a degree of polymerization of 45 (R f It is a straight-chain fluoroalkyl group with 6 carbon atoms with a fluorocarbon ratio of 1:1) mixed with antimony acetate, wherein the molar ratio of bishydroxyethyl terephthalate oligomer to ethylene glycol is 1:2, fluorosilicone The quality of the modifier is 6% of the quality of the bishydroxyethyl terephthalate oligomer, the consumption of antimony acetate is 0.013% of the quality of the bishydroxyethyl terephthalate oligomer, and the above mixture is under the protection of an inert gas Raise the temperature to 190°C, react for 1.5 hours, start vacuuming, and stir, and at the same time raise the temperature to 240°C, under the pressure of 0.1MPa, react for 1.5 hours, continue to increase the reaction temperature to 280°C, continue polycondensation under the pressure of 50Pa, and stir...

Embodiment 2

[0050] Mix bishydroxyethyl terephthalate oligomers with a degree of polymerization of 2 to 4, ethylene glycol, and antimony acetate, wherein the molar ratio of bishydroxyethyl terephthalate oligomers to ethylene glycol is 1:1.8, The consumption of antimony acetate is 0.013% of the bishydroxyethyl terephthalate oligomer quality, and this mixture is heated up to 200 ℃ under the protection of inert gas, and reacts for 1.3 hours; Start to vacuumize, start stirring, and heat up to 250 ℃ simultaneously, Under the pressure of 0.1MPa, after reacting for 15 minutes, stop the vacuum and stirring, and under the protection of inert gas, add the fluorosilicone modified with a polymerization degree of 45 in an amount of 6% of the mass of the bishydroxyethyl terephthalate oligomer. agent (R f Fluorocarbon ratio 1: 1 straight-chain fluoroalkyl group with 10 carbon atoms), after stirring for 15 minutes, continue to vacuumize, and react for 1 hour; continue to increase the reaction temperature ...

Embodiment 3

[0054] Mix bishydroxyethyl terephthalate oligomers with a degree of polymerization of 2 to 4, ethylene glycol, and antimony acetate, wherein the molar ratio of bishydroxyethyl terephthalate oligomers to ethylene glycol is 1:2.4, The consumption of antimony acetate is 0.013% of the bishydroxyethyl terephthalate oligomer quality, and the mixture is heated up to 210°C under the protection of an inert gas, and reacted for 1.4 hours; vacuumizing is started, stirring is started, and the temperature is raised to 245°C simultaneously, Under the pressure of 0.1MPa, after reacting for 15 minutes, stop the vacuum and stirring, and under the protection of inert gas, add the fluorosilicone modified with a polymerization degree of 45 in an amount of 12% of the mass of the bishydroxyethyl terephthalate oligomer. agent (R f Fluorocarbon ratio 1: 1 straight-chain fluoroalkyl group with 3 carbon atoms), after stirring for 15 minutes, continue vacuuming, and react for 1 hour; continue to increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com