A thin-layer cutting device for multi-interlayer model materials

A model material and cutting device technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., to achieve the effect of good thin layer homogeneity, avoid discreteness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

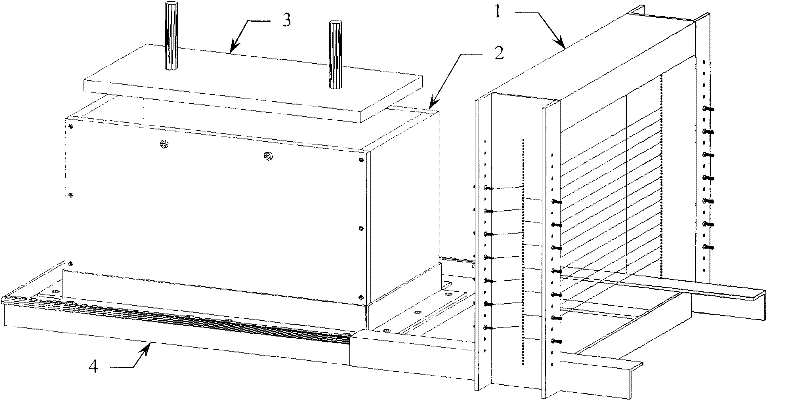

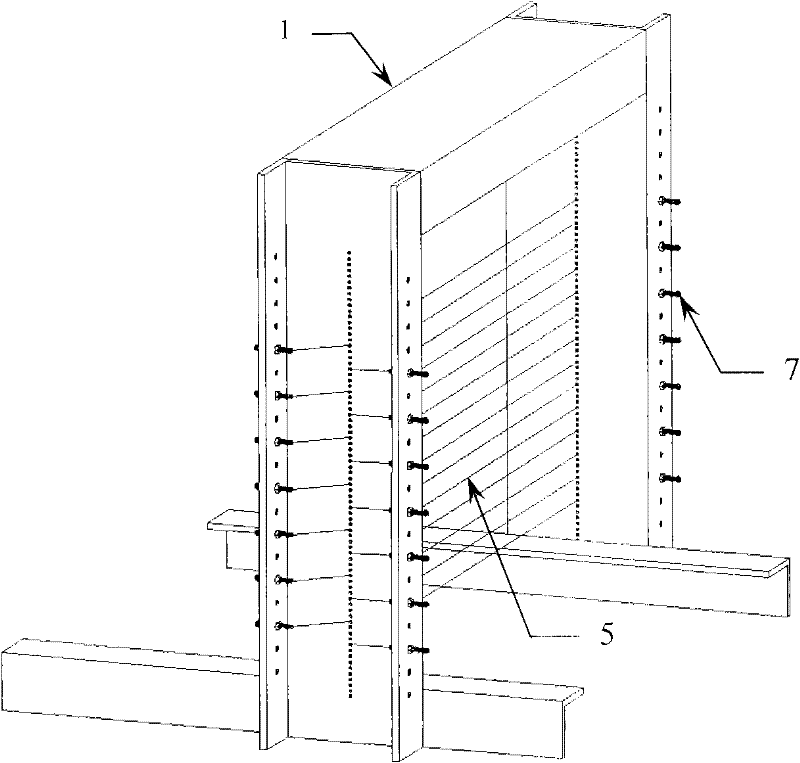

[0027] A thin-layer cutting device for multi-interlayer model materials, which includes: a cutting frame 1, a material box 2, a pressure bearing plate 3, and a base 4, and is characterized in that: the cutting frame 1 is installed on the base 4, and the material box 2 is installed on the In the groove of the base 4, the cutting frame 1 is pushed horizontally to drive a plurality of parallel steel wires 5 to horizontally cut the model material block to obtain multiple thin layers.

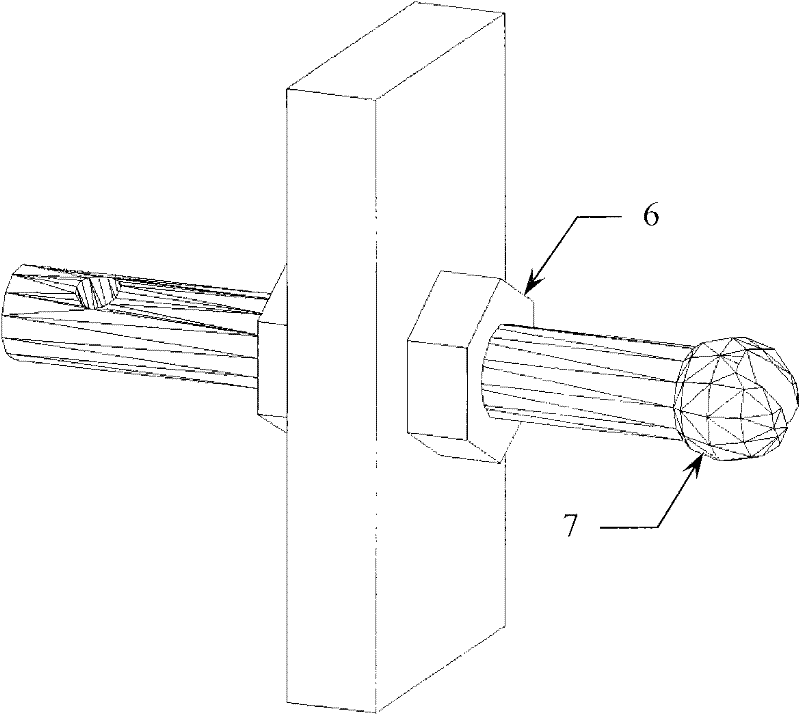

[0028] The main frame of the cutting frame 1 is welded by three channel steels and two angle steels, the two angle steels of the cutting frame 1 are stuck on the base 4, and one group (generally 10 or 11 or 12 or 13 or 14 or 15 or 16 or 17 or 18 or 19 or 20) parallel steel wires 5 with adjustable spacing.

[0029] The material box 2 is composed of five detachable plates, which are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com