Steelmaking-continuous casting production operation plan and real-time dispatching optimization method and system based on mixed intelligent optimization algorithm

An intelligent optimization algorithm and job planning technology, applied in the information field, can solve problems such as production equipment failure, low efficiency of production scheduling, lack of real-time supervision functions of production planning and scheduling in the manufacturing execution system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings.

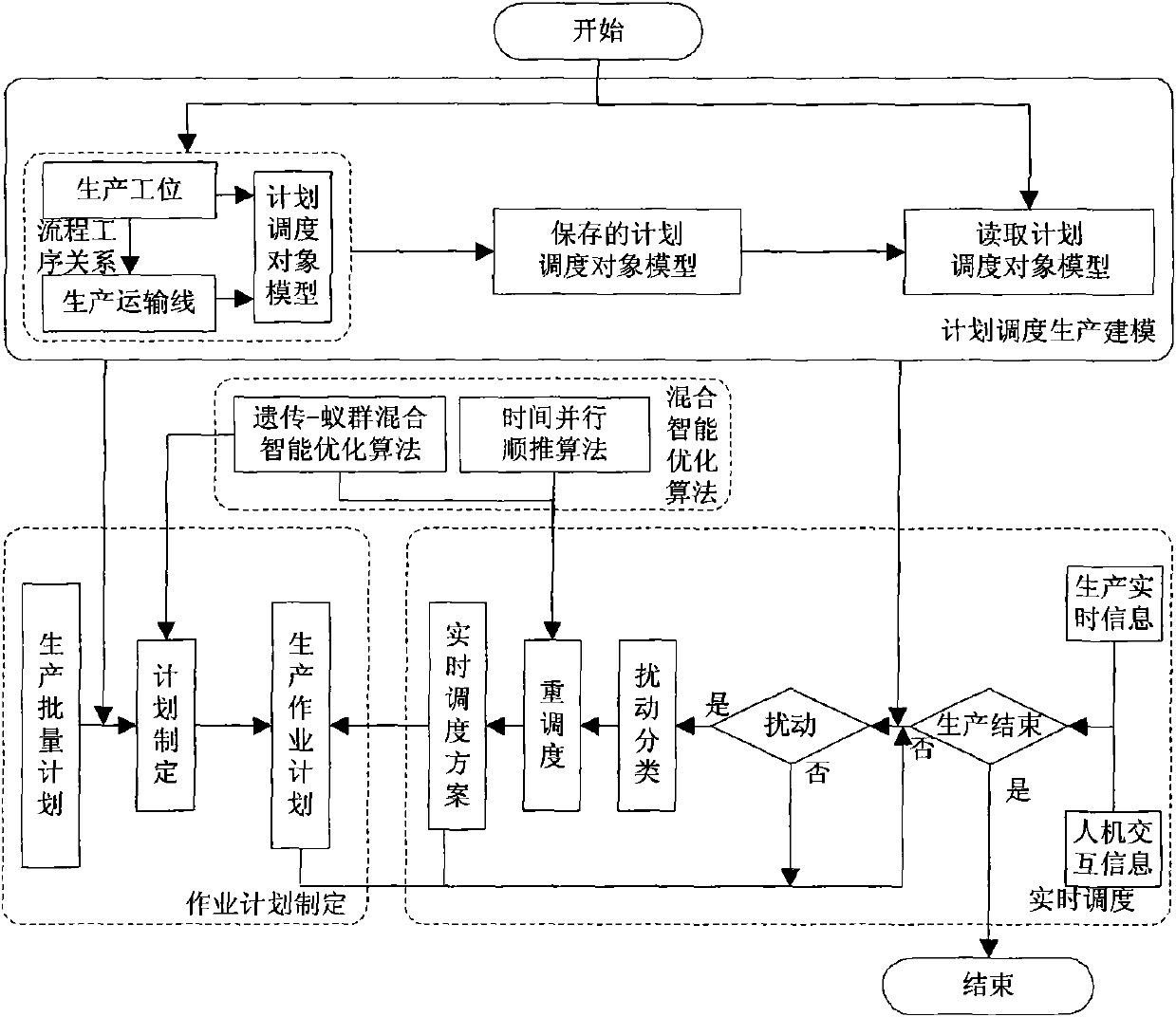

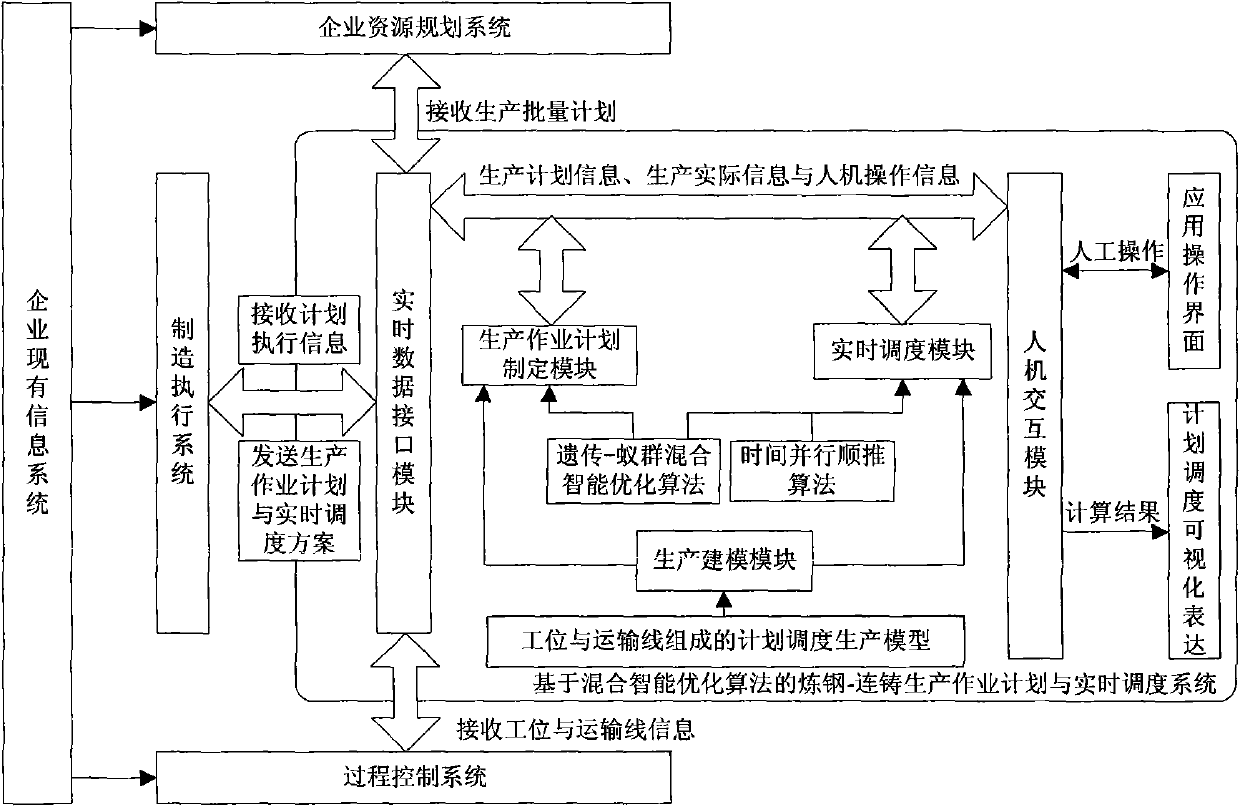

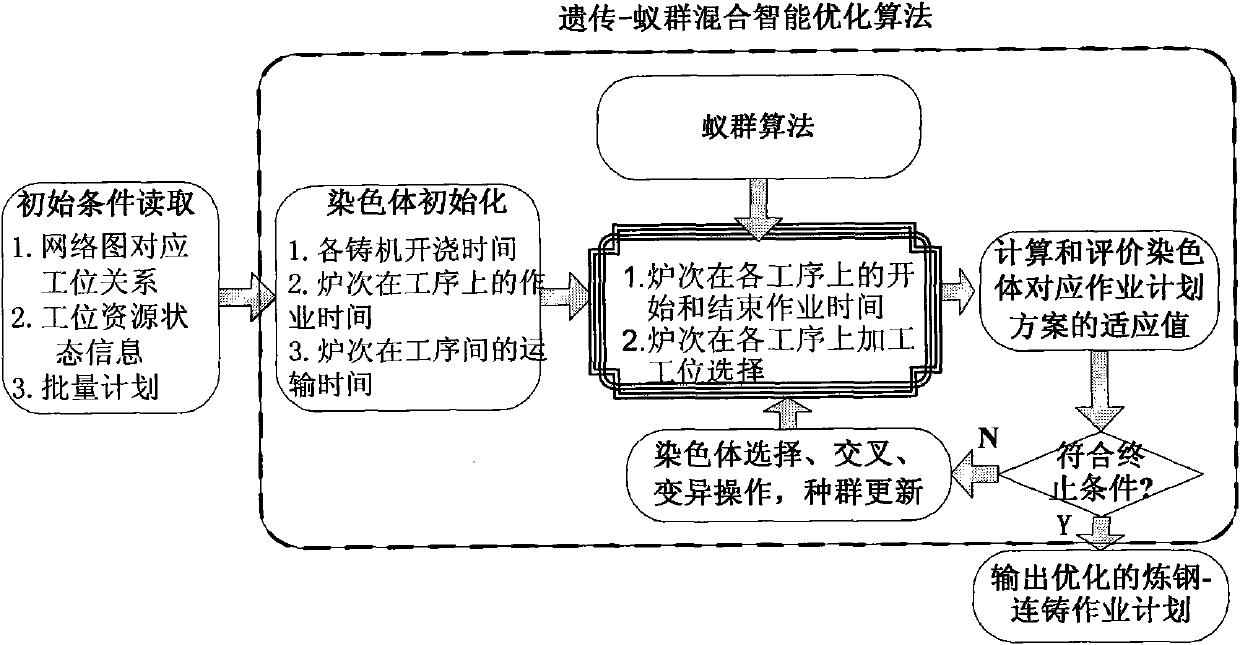

[0041] The steelmaking-continuous casting production operation planning and real-time scheduling optimization method based on the hybrid intelligent optimization algorithm includes three parts: planning and scheduling production modeling, production operation planning and real-time scheduling, and a combination of genetic-ant colony hybrid intelligent optimization algorithm and time parallel sequence A library of hybrid intelligent optimization algorithms for extrapolation, see figure 1 .

[0042] In production modeling, you can create a new planning and scheduling object model, or open an existing production model file for rapid modeling. The planning and scheduling object model is composed of the production process stations and the production and transportation lines related to the process processes.

[0043] The planning and scheduling object model is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com