Preparation method of TAT

A mass ratio, acetic anhydride technology, applied in the direction of organic chemistry, can solve the problems of lack of application prospects, large consumption of acetic anhydride, large consumption of acetic anhydride and acetyl chloride, etc., to achieve cost reduction, simple process, and constant yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

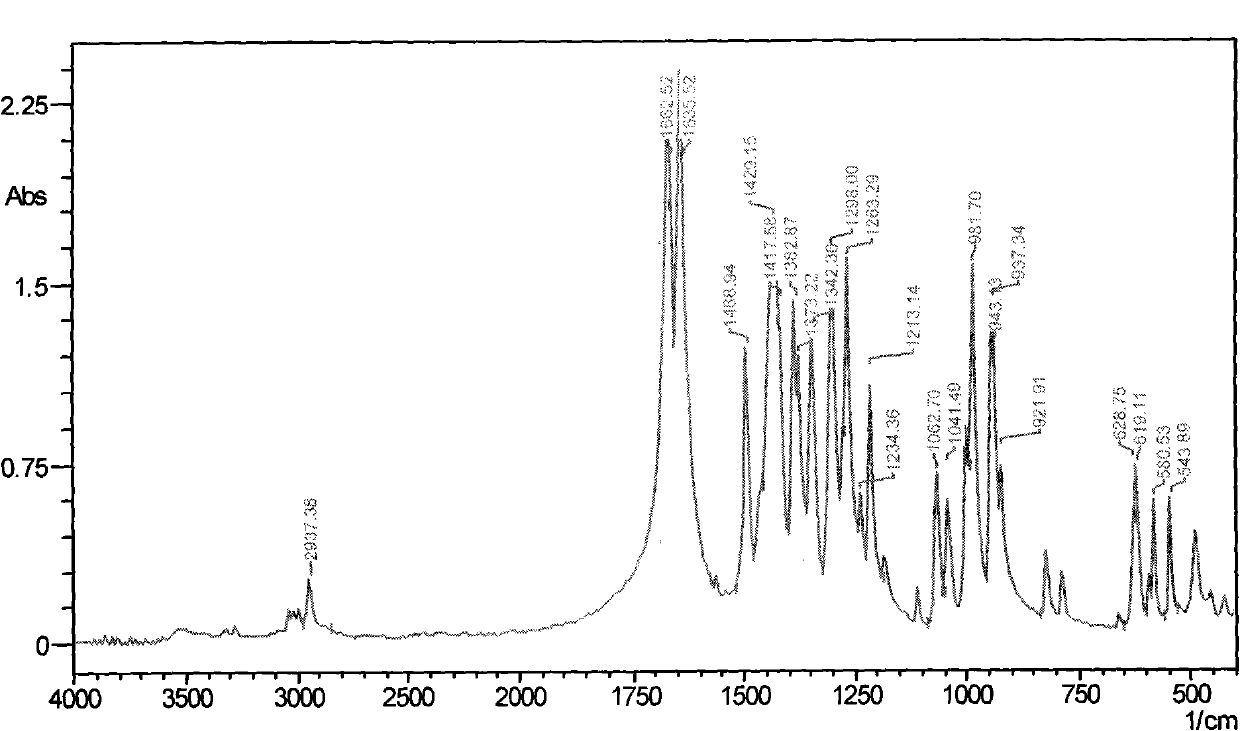

Image

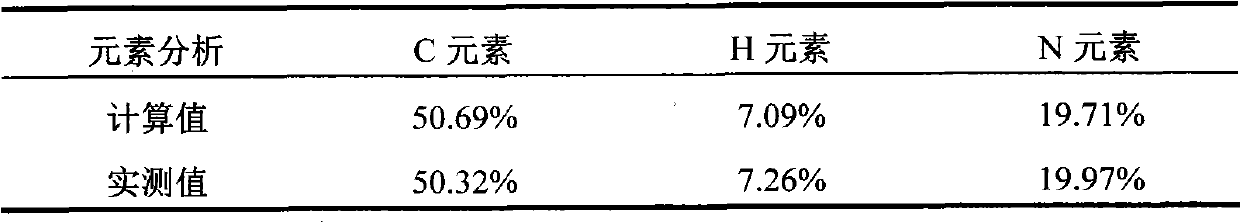

Examples

Embodiment 1

[0020] Add 7g (0.05mol) of HA, 3.1g (0.04mol) of ammonium acetate and 3.5g (0.2mol) of water into a round-bottomed flask, stir to form a slurry, control the temperature of the system at 5-10°C, and stir for 30 minutes Slowly add 15 g of acetic anhydride (0.15 mol) dropwise. After the addition, control the temperature below 10°C and continue stirring for 30 min to complete the reaction. The temperature of the reaction solution was raised to 120° C. and distilled under reduced pressure. 20 mL of acetone was added to the obtained product and heated to boil for recrystallization to obtain 10.6 g of white crystals of DAPT with a yield of 100% (based on the added HA).

[0021] Add 5g (0.024mol) of DAPT and 9.6g (0.09mol) of acetic anhydride into the reactor, heat up to 110C for 2h under stirring, cool down to 30°C, add 2mL of water for 1.5h, distill under reduced pressure, and dilute the obtained The yellow solid product was recrystallized with boiling acetone to obtain 5.48 g of th...

Embodiment 2

[0031] Add 9.5g (0.068mol) of HA, 5g (0.065mol) of ammonium acetate and 6mL (0.343mol) of water (water temperature 5-10°C) into a 50mL round bottom flask, stir to form a slurry, and control the temperature of the system at 5-10°C. ℃, slowly add 18g of acetic anhydride (0.18mol) dropwise within 50min under stirring, after the addition, control the temperature below 10℃, and continue stirring for 40min to complete the reaction. The reaction solution was heated to 120°C for distillation under reduced pressure, 40 mL of acetone was added to the distilled product, and after heating and boiling, recrystallization was carried out to obtain 14.38 g of white crystals of DAPA, with a yield of 100% (based on the added HA).

[0032] Add 8gDAPT and 16.7g acetic anhydride into a 100mL reactor, raise the temperature to 100°C for 2h under stirring, cool down to 30°C, add 4mL of water to react for 1.5h, distill under reduced pressure, and recrystallize the obtained pale yellow solid product wit...

Embodiment 3

[0034] Add 22g (0.157mol) of HA, 9.5g (0.123mol) of ammonium acetate and 11mL (0.628mol) of water (water temperature 5-10°C) into a 50mL round bottom flask, stir to form a slurry, and control the temperature of the system at 5-10°C. ℃, slowly add 50g of acetic anhydride (0.5mol) dropwise within 30min under stirring, after the addition, control the temperature below 10℃, continue stirring for 35min to complete the reaction. The temperature of the reaction solution was raised to 120° C. for distillation under reduced pressure, 30 mL of acetone was added to the product, and recrystallization was carried out after heating and boiling to obtain 33.14 g of white crystals of DAPA, with a yield of 100% (based on the added HA).

[0035] Add 10gDAPT and 19.2g acetic anhydride into a 100mL reactor, raise the temperature to 110°C for 2h under stirring, cool down to 30°C, add 3mL of water to react for 1.5h, distill under reduced pressure, and recrystallize the obtained pale yellow solid produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com