Complete-reclaiming process of down wastewater and special feather fishing machine without driving force

A hair removal machine and driving force technology, applied in the direction of biological water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of sludge load reduction, management difficulties, waste, etc., to achieve Effect of reducing processing load and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

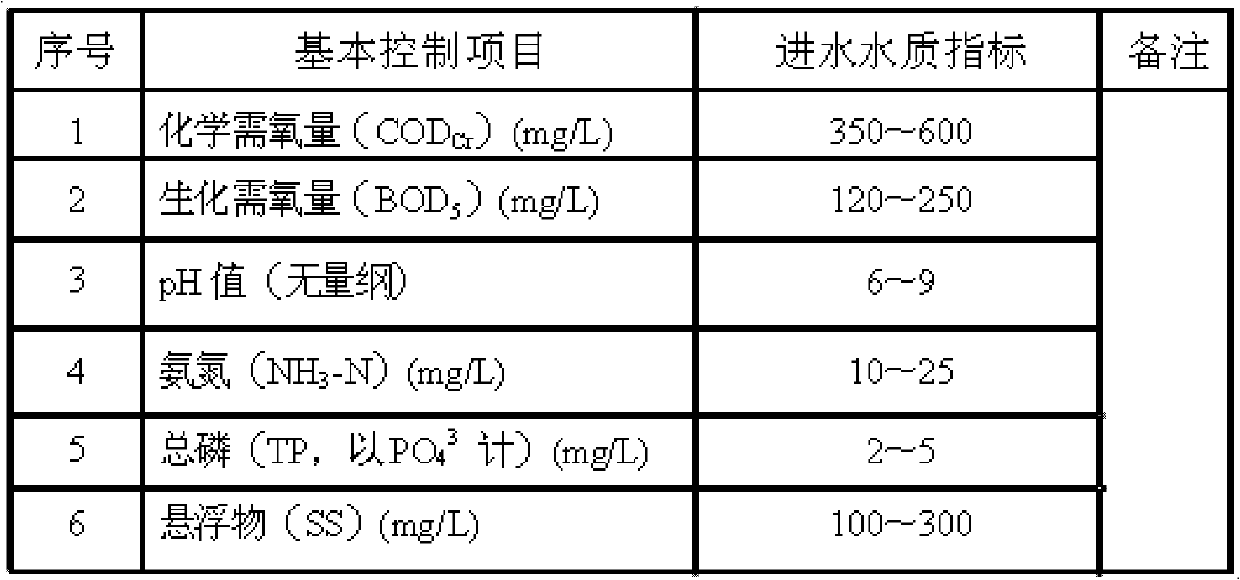

[0049] A large down product factory discharges 6,000 tons of waste water per day, and the influent water quality indicators:

[0050]

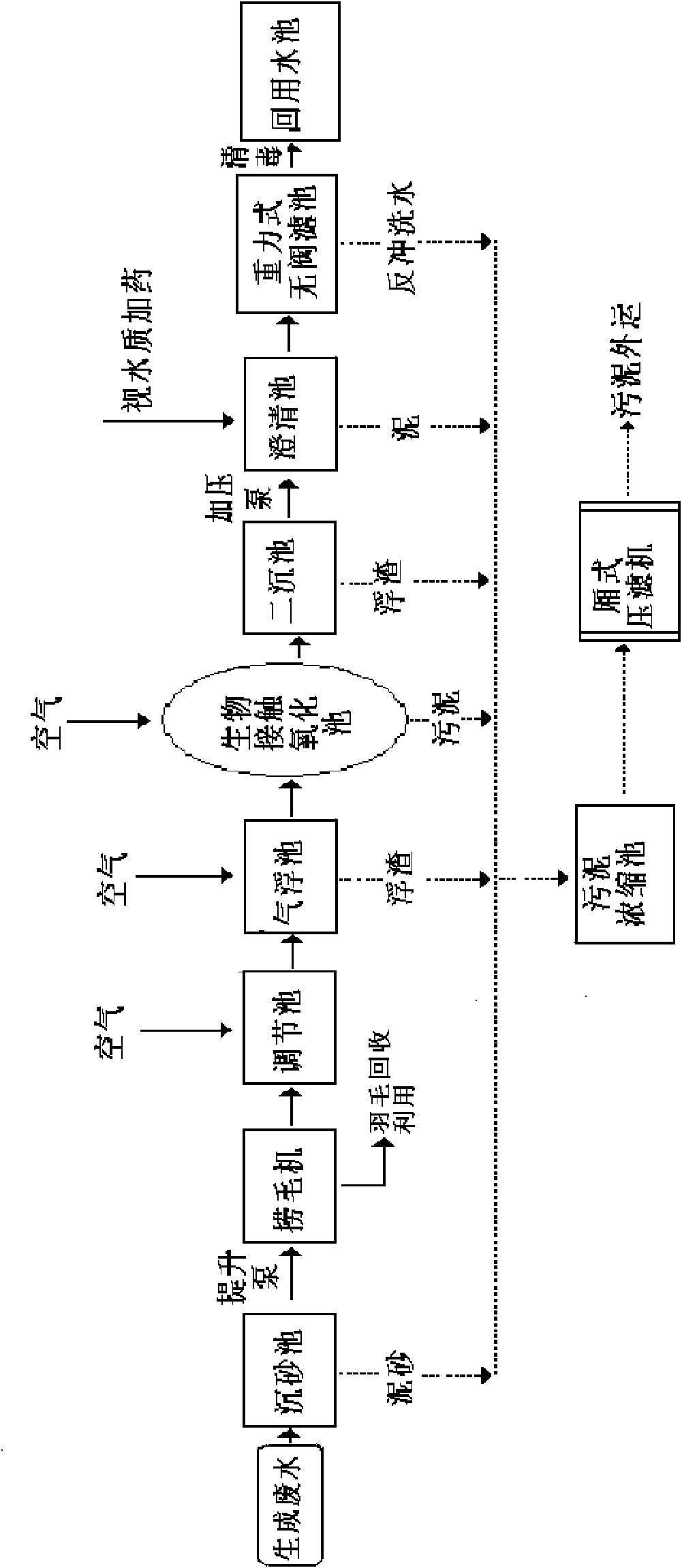

[0051] treatment techniques such as figure 1 The flow shown:

[0052] 1) The washing water, drying water and other waste water of each production line are introduced into the grit chamber through open ditch and hidden pipes to deposit mud and sand;

[0053] 2) The water in the grit chamber is lifted by the pump, and after the fine suspended matter such as down flakes is picked up by the hair scooping machine, it enters the regulating tank;

[0054]3) Pre-aeration is carried out in the regulating tank to fully homogenize the water quality and quantity;

[0055] 4) The effluent from the regulating tank flows into the air flotation tank by itself to remove a large amount of tiny suspended solids in the wastewater, so as to reduce the load of subsequent biochemical treatment;

[0056] 5) The effluent from the air flotation tank flows into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com