Processing technique for residual papermaking black liquor

A technology for papermaking black liquor and processing technology, applied in papermaking, textile and papermaking, fiber raw material processing, etc., can solve problems such as damage to water bodies, farmland, fish ponds, hidden dangers of environmental pollution, and spillage of black liquor in ponds, and achieve remarkable treatment effects. , Simple operation and management, reasonable processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

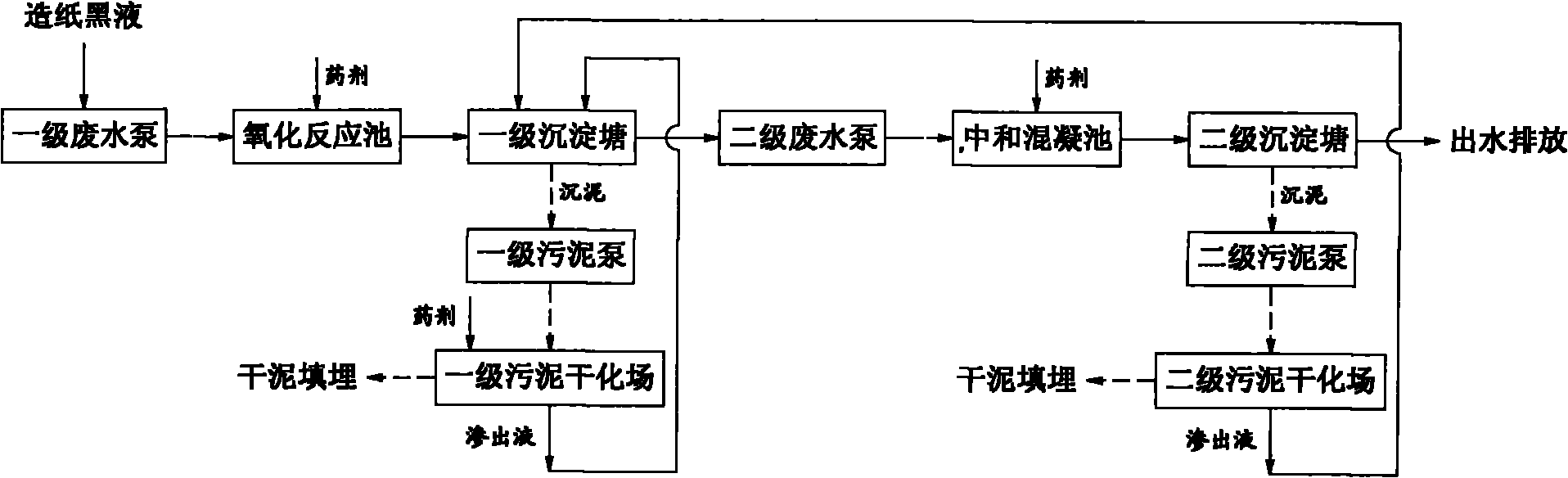

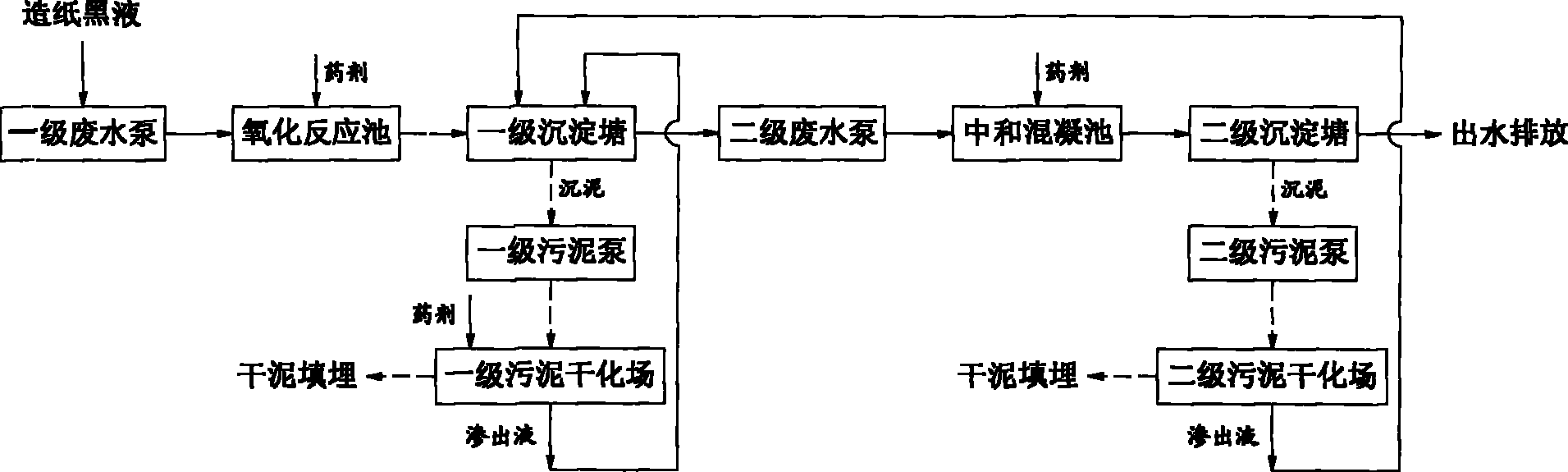

[0012] Such as figure 1 Shown, the present invention processes the papermaking black liquor that contains lignin, polysaccharide, and it processes according to the following steps:

[0013] 1), oxidation reaction; add sulfuric acid, ferrous sulfate and hydrogen peroxide to the treated papermaking black liquor, adjust the pH value of the papermaking black liquor to 4-5; then, input the mixed black liquor with a pH value of 4-5 The first-level sedimentation pond, settling for 12-16 hours to obtain light yellow supernatant and first-level sludge, and the first-level sludge is discharged into the drying field; the concentration of sulfuric acid is 98%, and the black liquor is 5.0-6.5Kg / m 3 Proportional dosing; ferrous sulfate is in powder form, mixed with black liquor at 7.0-8.0Kg / m 3 Proportional dosing; the concentration of hydrogen peroxide is 30%, and the black liquor is 3.0-4.0Kg / m 3 Ratio dosing;

[0014] 2) Neutralization and coagulation: input the light yellow superna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com